Laser Cutter Wood Thickness: A Comprehensive Guide

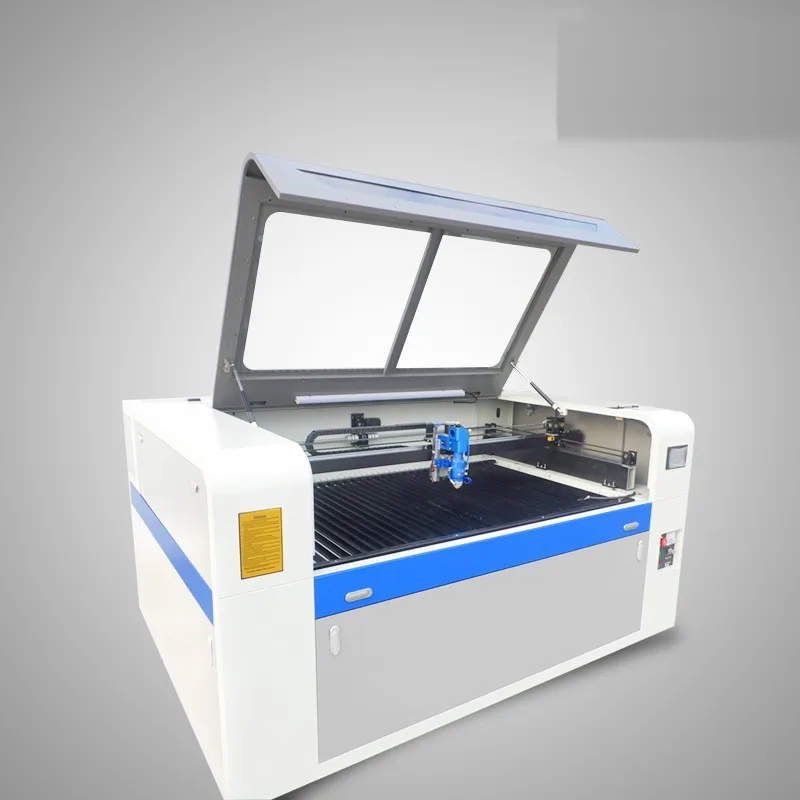

Laser cutters have revolutionized the woodworking industry, allowing for precise and intricate cuts with minimal effort. One of the key considerations when using a laser cutter is the thickness of the wood being cut. In this comprehensive guide, we will delve into the various aspects of laser cutter wood thickness, including the optimal thickness for different applications, factors affecting cut quality, and safety guidelines.

Optimal Wood Thickness for Laser Cutting

Table of Content

The ideal wood thickness for laser cutting depends on the specific project requirements and the capabilities of the laser cutter. Generally, the following thickness ranges are considered optimal:

Factors Affecting Cut Quality

Several factors influence the quality of laser cuts on wood, including:

DOWNLOAD SVG FILES FOR LASER CUTTING

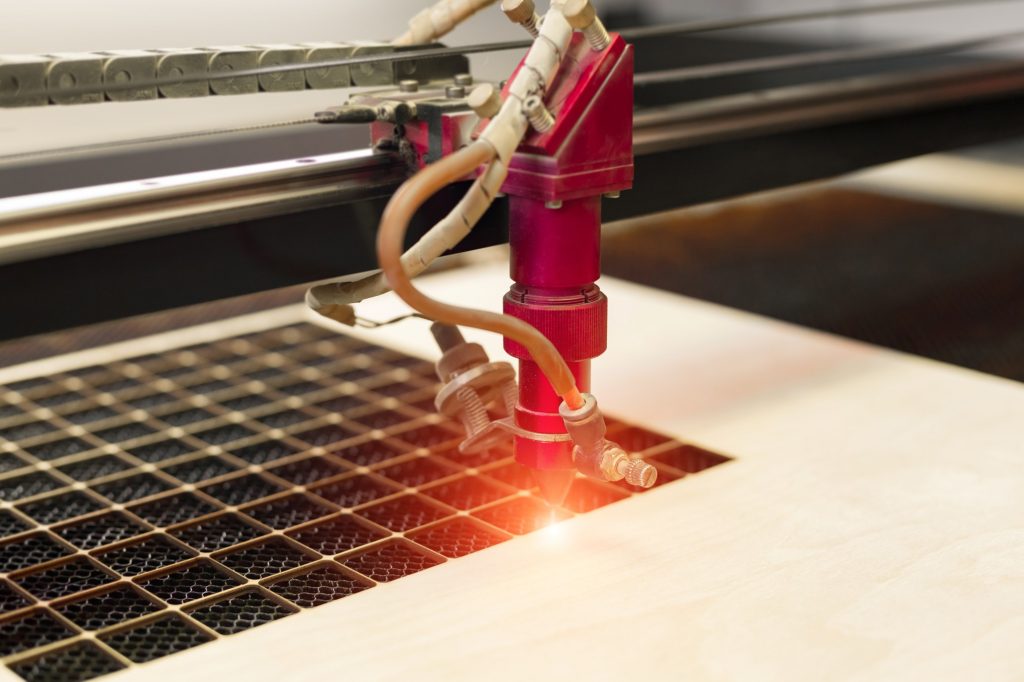

1. Laser Power: Higher laser power allows for cutting thicker wood and achieving cleaner cuts.

2. Beam Focus: A well-focused laser beam ensures precise cutting and minimal charring.

3. Wood Type: Different wood species have varying densities and grain patterns, affecting the cutting speed and quality.

4. Cutting Speed: The optimal cutting speed depends on the wood thickness and the laser power. Too high speeds can result in rough cuts, while too low speeds can lead to excessive burning.

Optimal Wood Thickness for Laser Cutting

- Wooden Toys Laser Cutting Wooden Toys Laser Cutting: A Comprehensive Guide

- Buy Wood Laser Cutter H1: Unleash Your Creativity: A Comprehensive Guide To Buying The Perfect Wood Laser Cutter

- Best Laser Wood Cutter For Small Business Best Laser Wood Cutter For Small Business: A Comprehensive Guide

- Wood Laser Cutter Price Wood Laser Cutter Price: A Comprehensive Guide To Costs And Considerations

- Auto Wood Laser Cutter Auto Wood Laser Cutter: Precision Cutting For Intricate Designs

The ideal wood thickness for laser cutting depends on the specific project requirements and the capabilities of the laser cutter. Generally, the following thickness ranges are considered optimal:

- Thin Wood (0.1-0.25mm): Suitable for delicate projects such as laser engraving, intricate cutouts, and veneers.

- Medium Wood (0.25-0.5mm): Ideal for laser cutting small objects, models, and decorative pieces.

- Thick Wood (0.5-1mm): Can be cut with higher-powered lasers for larger projects, such as furniture components, toys, and signs.

DOWNLOAD SVG FILES FOR LASER CUTTING

5. Air Assist: A jet of compressed air during cutting helps remove smoke and debris, improving cut quality and reducing charring.

Safety Guidelines for Laser Cutting Wood

Laser cutting wood involves potential hazards, and adhering to the following safety guidelines is crucial:

1. Proper Ventilation: Ensure adequate ventilation to remove smoke and fumes generated during cutting.

2. Eye Protection: Wear appropriate laser safety glasses to protect your eyes from laser radiation.

3. Fire Safety: Keep a fire extinguisher nearby and monitor the cutting area for potential fire hazards.

4. Material Selection: Only use wood that is compatible with laser cutting and free of knots or impurities.

5. Secure Workpiece: Secure the workpiece firmly to prevent movement during cutting.

Conclusion

Understanding laser cutter wood thickness is essential for achieving optimal results and ensuring safety. By considering the appropriate thickness for the project, optimizing cutting parameters, and adhering to safety guidelines, you can unlock the full potential of your laser cutter and create precise and intricate woodworking projects.

FAQs

1. What is the maximum wood thickness that can be cut with a laser cutter?

The maximum wood thickness that can be cut with a laser cutter depends on the laser power. Generally, laser cutters can cut wood up to 1-2mm thick with high precision.

2. Can I cut plywood with a laser cutter?

Yes, you can cut plywood with a laser cutter. However, it is important to use high-quality plywood that is free of voids or knots.

3. What is the best wood for laser cutting?

Hardwoods such as oak, maple, and walnut are suitable for laser cutting due to their durability and fine grain patterns.

4. How do I clean up after laser cutting wood?

After laser cutting wood, it is important to remove any smoke or debris from the workpiece and the cutting area. Use a damp cloth or compressed air to clean the surfaces.

5. What are the environmental considerations for laser cutting wood?

Laser cutting wood releases smoke and fumes, so it is important to use proper ventilation and consider the environmental impact of the process.