Laser Cutting 3D Prints: A Comprehensive Guide

Introduction

Laser cutting is a precise and versatile manufacturing technique that utilizes a focused laser beam to cut or engrave various materials. In recent years, it has gained significant traction for post-processing 3D prints, enabling the creation of intricate and customized designs. This article provides a comprehensive guide to laser cutting 3D prints, covering the process, benefits, challenges, and best practices.

Table of Content

- 1 Laser Cutting 3D Prints: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H2: Process of Laser Cutting 3D Prints

- 1.3 H2: Benefits of Laser Cutting 3D Prints

- 1.4 H2: Process of Laser Cutting 3D Prints

- 1.5 H2: Challenges of Laser Cutting 3D Prints

- 1.6 H2: Best Practices for Laser Cutting 3D Prints

- 1.7 H2: Conclusion

- 1.8 FAQs

H2: Process of Laser Cutting 3D Prints

1. Material Selection:

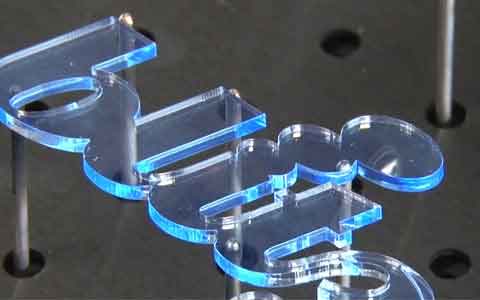

Suitable materials for laser cutting include acrylic, wood, leather, cardboard, and certain plastics. The material’s thickness and composition determine the laser power and speed settings required.

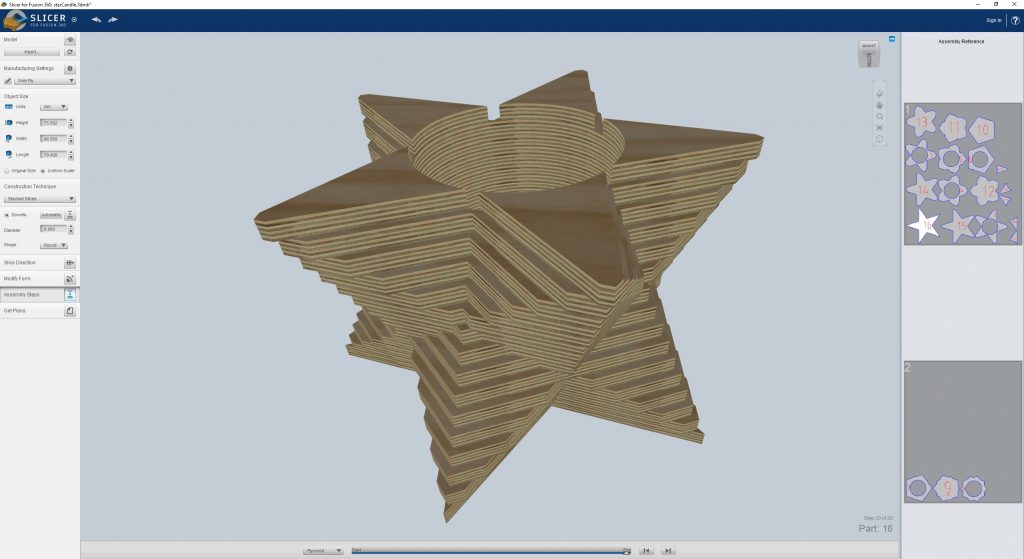

2. File Preparation:

The 3D model is exported into a compatible file format, typically SVG or DXF. The file should contain the desired cut or engraving design.

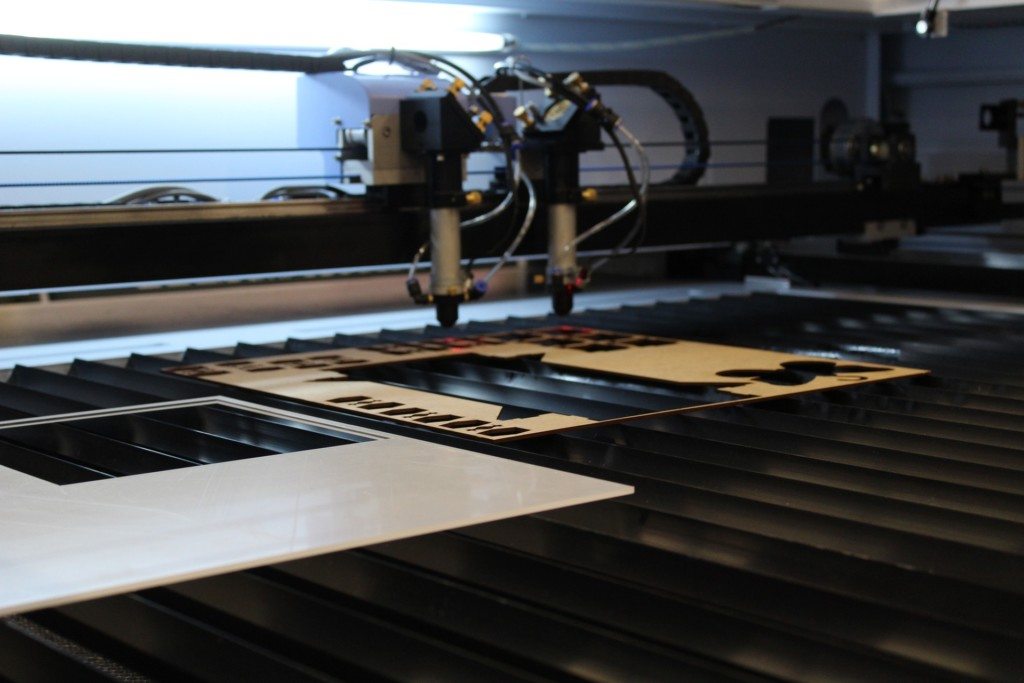

3. Laser Machine Setup:

The laser cutter is calibrated and the laser power, speed, and focus are adjusted based on the material and design.

4. Laser Cutting:

The 3D print is placed on the laser cutting bed and the laser is activated. The laser beam follows the design path, cutting or engraving the material.

H2: Benefits of Laser Cutting 3D Prints

1. Precision and Accuracy:

Laser cutting is a precise and versatile manufacturing technique that utilizes a focused laser beam to cut or engrave various materials. In recent years, it has gained significant traction for post-processing 3D prints, enabling the creation of intricate and customized designs. This article provides a comprehensive guide to laser cutting 3D prints, covering the process, benefits, challenges, and best practices.

- Laser Cut 3d Puzzle Dxf Files Laser Cut 3D Puzzle DXF Files: An In-Depth Guide For Hobbyists And Designers

- Laser Cut 3d Pop Cards Laser Cut 3D Pop Cards: A Captivating Expression Of Creativity And Emotion

- Laser Cut 3d Terrain Laser Cut 3D Terrain: Unleashing The Power Of Precision And Creativity

- 3d Laser Engraving Machine 3D Laser Engraving Machine: Unlocking Precision And Versatility In Manufacturing

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

H2: Process of Laser Cutting 3D Prints

The laser cutting process for 3D prints involves the following steps:

1. Material Selection:

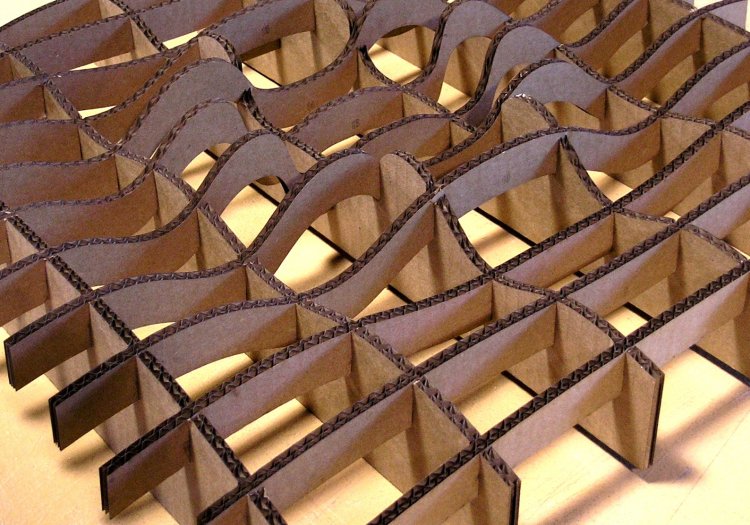

Suitable materials for laser cutting include acrylic, wood, leather, cardboard, and certain plastics. The material’s thickness and composition determine the laser power and speed settings required.

2. File Preparation:

Laser cutting offers exceptional precision and accuracy, ensuring clean and sharp cuts or engravings.

2. Intricate Designs:

Laser cutting enables the creation of intricate and detailed designs that would be challenging or impossible to achieve through traditional methods.

3. Material Versatility:

A wide range of materials can be laser cut, allowing for customization and the creation of unique products.

4. Speed and Efficiency:

Laser cutting is a relatively fast and efficient process, reducing production time and costs.

H2: Challenges of Laser Cutting 3D Prints

1. Material Distortion:

Certain materials may warp or distort during laser cutting due to the heat generated.

2. Laser Fading:

The laser beam can potentially fade or discolor the material, especially with prolonged exposure.

3. Smoke and Fumes:

Laser cutting releases smoke and fumes that require proper ventilation and filtration.

H2: Best Practices for Laser Cutting 3D Prints

1. Ventilation and Safety:

Ensure adequate ventilation and wear appropriate protective gear during laser cutting.

2. Material Testing:

Test different laser settings on scrap material to determine the optimal parameters for the desired result.

3. Design Optimization:

Optimize the design to minimize material distortion and ensure proper fit and alignment.

4. Regular Maintenance:

Regularly clean and maintain the laser cutter to ensure optimal performance and safety.

H2: Conclusion

Laser cutting offers a powerful tool for post-processing 3D prints, enabling the creation of precise, intricate, and customized designs. By understanding the process, benefits, challenges, and best practices, users can effectively utilize laser cutting to enhance their 3D printing projects.

FAQs

1. What is the best laser power for cutting 3D prints?

The optimal laser power depends on the material and thickness. It is recommended to start with lower power settings and gradually increase them as needed.

2. How do I prevent material distortion during laser cutting?

Use materials with high thermal stability or consider using a cooling system to minimize heat-induced distortion.

3. Can I laser cut 3D prints made of metal?

Yes, but it requires specialized laser cutters designed for metal cutting.

4. What is the maximum thickness of material that can be laser cut?

The maximum thickness depends on the laser cutter’s power and the material’s properties. Generally, thicker materials require higher laser power.

5. Is laser cutting safe for indoor use?

Laser cutting requires proper ventilation and filtration systems to remove smoke and fumes. It is not recommended for indoor use without adequate safety precautions.