Laser Cutting Box: A Comprehensive Guide to Precision Cutting

Introduction

Laser cutting boxes, also known as laser cutters, have revolutionized the manufacturing industry with their ability to cut intricate designs and shapes with unparalleled precision. These machines utilize a focused laser beam to vaporize or melt material, allowing for clean and precise cuts on a wide range of materials. In this comprehensive guide, we will delve into the world of laser cutting boxes, exploring their capabilities, applications, and factors to consider when choosing the right machine for your needs.

Table of Content

- 1 Laser Cutting Box: A Comprehensive Guide to Precision Cutting

- 1.1 Introduction

- 1.2 How Does a Laser Cutting Box Work?

- 1.3 Types of Laser Cutting Boxes

- 1.4 Materials Suitable for Laser Cutting

- 1.5 How Does a Laser Cutting Box Work?

- 1.6 Types of Laser Cutting Boxes

- 1.7 Applications of Laser Cutting Boxes

- 1.8 Factors to Consider When Choosing a Laser Cutting Box

- 1.9 Conclusion

- 1.10 FAQs

How Does a Laser Cutting Box Work?

As the laser beam strikes the material, it interacts with its atoms and molecules, causing them to vaporize or melt. This process creates a narrow kerf, or cut, in the material. The laser beam is precisely controlled by computer software, allowing for highly accurate and repeatable cuts.

Types of Laser Cutting Boxes

Laser cutting boxes come in a variety of sizes and configurations to meet the specific needs of different industries and applications. The main types include:

- Flatbed Laser Cutters: These machines have a flatbed work surface on which the material is placed. The laser head moves over the workpiece, cutting out the desired shapes.

- Gantry Laser Cutters: Gantry laser cutters feature a gantry system that moves the laser head over the workpiece. This allows for cutting on larger materials and more complex shapes.

- Galvo Laser Cutters: Galvo laser cutters use a high-speed galvo mirror system to direct the laser beam. They are suitable for cutting small, intricate shapes with high precision.

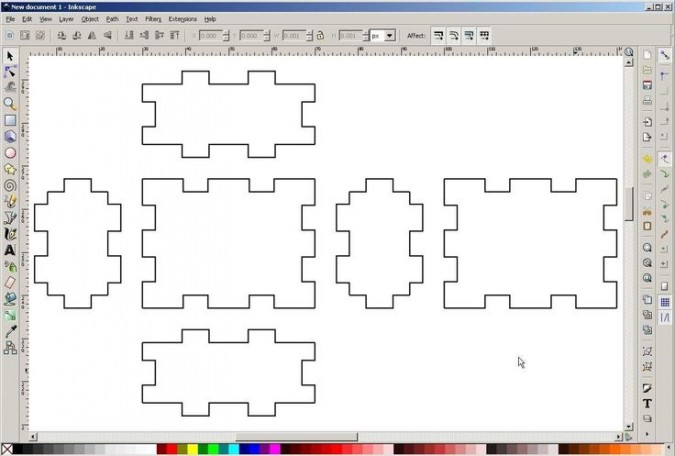

DOWNLOAD SVG FILES FOR LASER CUTTING

Materials Suitable for Laser Cutting

Laser cutting boxes can cut a wide range of materials, including:

Laser cutting boxes, also known as laser cutters, have revolutionized the manufacturing industry with their ability to cut intricate designs and shapes with unparalleled precision. These machines utilize a focused laser beam to vaporize or melt material, allowing for clean and precise cuts on a wide range of materials. In this comprehensive guide, we will delve into the world of laser cutting boxes, exploring their capabilities, applications, and factors to consider when choosing the right machine for your needs.

- Laser Cutting Cardboard Laser Cutting Cardboard: A Comprehensive Guide

- Laser Cut Paper Box Laser Cut Paper Box: An Exquisite Craft For Unparalleled Presentations

- Laser Cut Birthday Cards Laser Cut Birthday Cards: A Unique And Personalized Way To Celebrate Special Occasions

- Laser Cut Happy Birthday Sign Laser Cut Happy Birthday Sign: A Unique And Personalized Way To Celebrate

- Laser Cut Happy Birthday Laser Cut Happy Birthday: A Comprehensive Guide To Crafting Personalized Celebrations

How Does a Laser Cutting Box Work?

Laser cutting boxes operate on the principle of laser ablation, which involves using a high-powered laser beam to remove material from a surface. The laser beam is generated by a laser source, typically a carbon dioxide (CO2) or fiber laser, and is focused through a series of lenses and mirrors onto the workpiece.

DOWNLOAD SVG FILES FOR LASER CUTTING

As the laser beam strikes the material, it interacts with its atoms and molecules, causing them to vaporize or melt. This process creates a narrow kerf, or cut, in the material. The laser beam is precisely controlled by computer software, allowing for highly accurate and repeatable cuts.

Types of Laser Cutting Boxes

Laser cutting boxes come in a variety of sizes and configurations to meet the specific needs of different industries and applications. The main types include:

- Metals: Aluminum, stainless steel, mild steel, copper, brass

- Plastics: Acrylic, polycarbonate, polyethylene, polypropylene

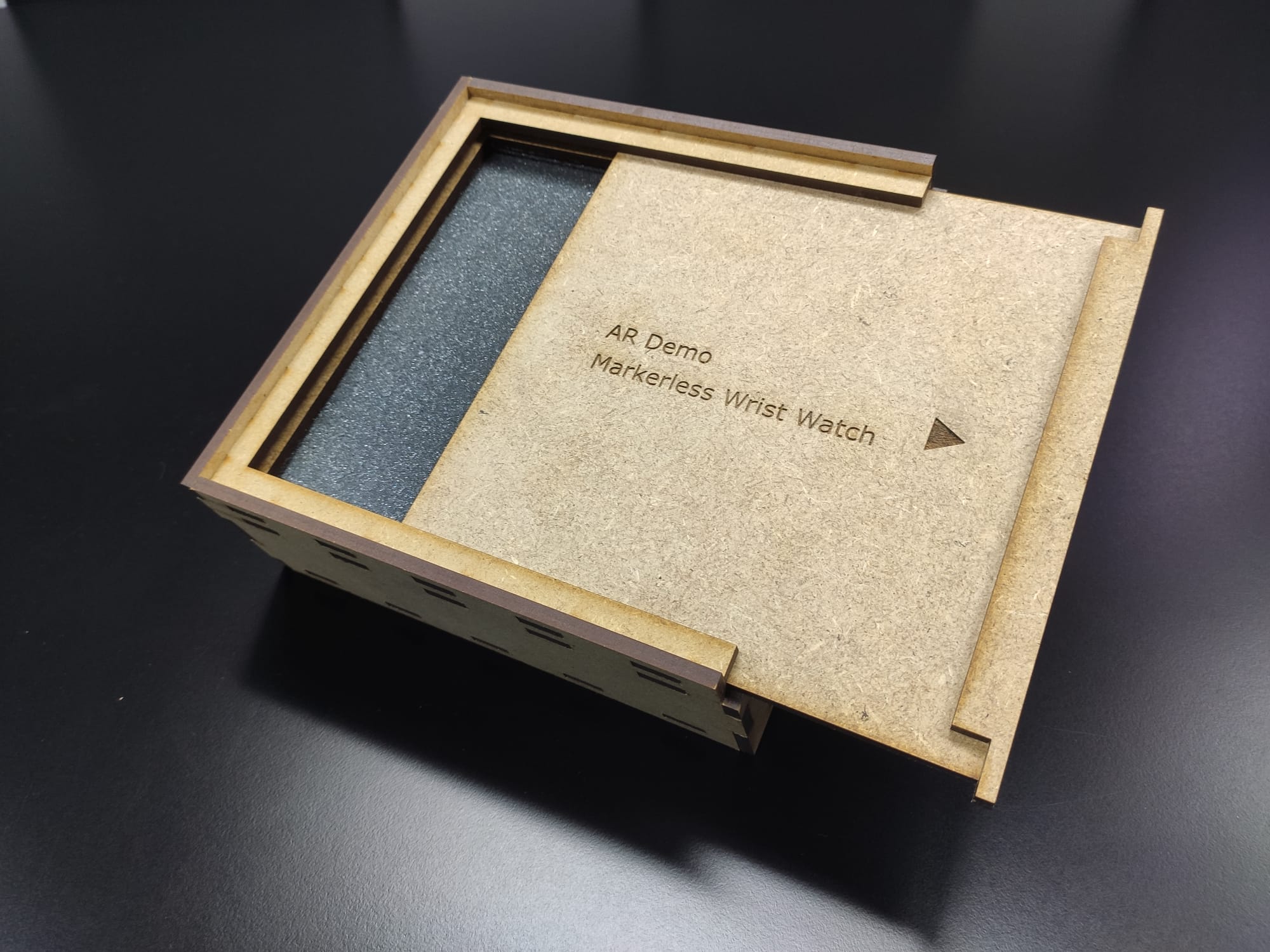

- Wood: Plywood, MDF, hardwoods, softwoods

- Glass: Tempered glass, float glass

- Fabric: Polyester, nylon, cotton

Applications of Laser Cutting Boxes

Laser cutting boxes have numerous applications across various industries, including:

- Fabrication: Cutting sheet metal, tubing, and other components for manufacturing

- Prototyping: Creating prototypes and models for design verification

- Art and Design: Cutting intricate shapes for sculptures, jewelry, and decorative items

- Medical: Cutting medical devices, implants, and surgical instruments

- Automotive: Cutting automotive parts, such as body panels and exhaust systems

Factors to Consider When Choosing a Laser Cutting Box

When selecting a laser cutting box, it is important to consider several factors:

- Laser Power: The laser power determines the thickness and types of materials that can be cut.

- Work Area: The work area size determines the maximum dimensions of the materials that can be processed.

- Cutting Speed: The cutting speed affects the productivity and efficiency of the machine.

- Precision: The precision of the laser cut depends on factors such as the laser beam quality and the machine’s motion control system.

- Software: The software used to control the laser cutter determines its ease of use and the range of features available.

- Price: Laser cutting boxes range in price from a few thousand dollars to hundreds of thousands of dollars, depending on the capabilities and features.

Conclusion

Laser cutting boxes offer a versatile and precise solution for cutting a wide range of materials. By understanding the principles of laser cutting, the different types of machines available, and the factors to consider when choosing a machine, you can select the right laser cutter for your specific needs. This powerful technology has transformed manufacturing and design industries, enabling the creation of intricate shapes and components with unparalleled accuracy and efficiency.

FAQs

Q: What are the benefits of using a laser cutting box?

A: Laser cutting boxes offer several benefits, including precision cutting, fast processing, high repeatability, and the ability to cut complex shapes.

Q: What materials can be cut with a laser cutting box?

A: Laser cutting boxes can cut a wide range of materials, including metals, plastics, wood, glass, and fabric.

Q: How does the laser power affect the cutting process?

A: The laser power determines the thickness and types of materials that can be cut. Higher laser power allows for cutting thicker materials and harder materials.

Q: What is the difference between a flatbed laser cutter and a gantry laser cutter?

A: Flatbed laser cutters have a flatbed work surface, while gantry laser cutters have a gantry system that moves the laser head over the workpiece. Gantry laser cutters are suitable for cutting larger materials and more complex shapes.

Q: How do I choose the right laser cutting box for my needs?

A: When selecting a laser cutting box, consider factors such as laser power, work area size, cutting speed, precision, software, and price. Determine the specific requirements of your application and choose a machine that meets those needs.