Laser Cutting Machine 3D Model: A Comprehensive Guide

Introduction

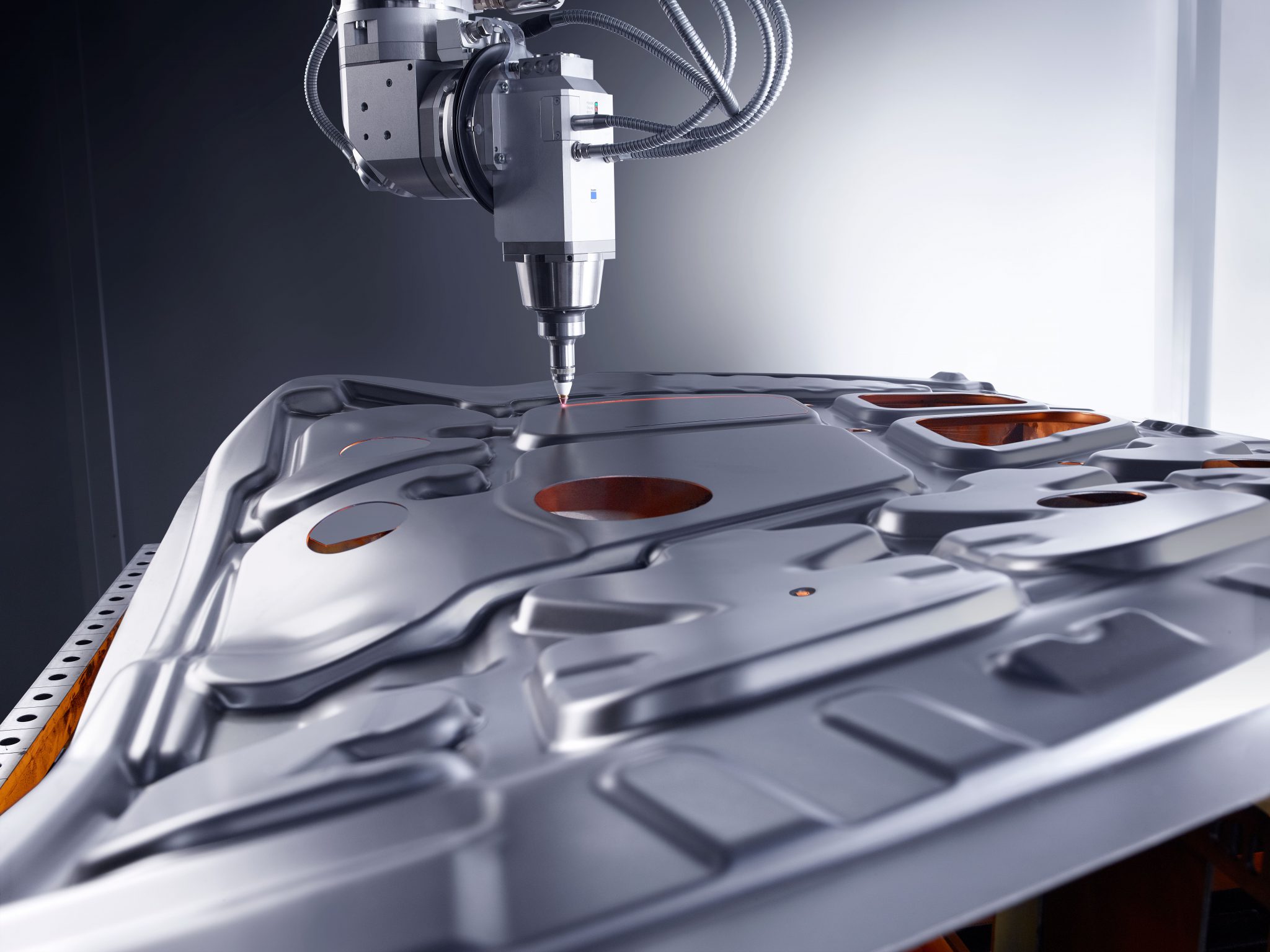

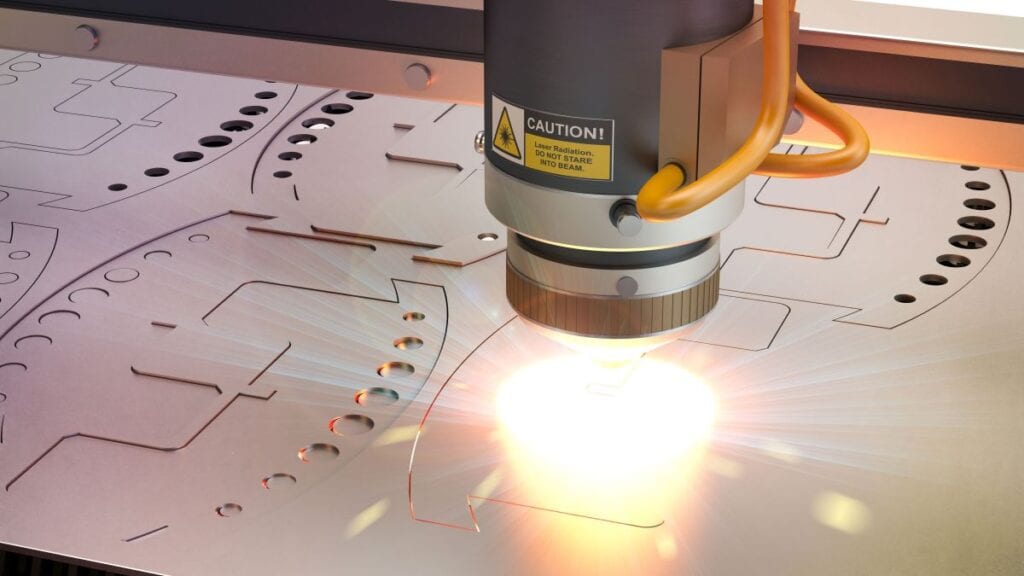

Laser cutting machines have revolutionized the manufacturing industry, enabling precise and intricate cutting of various materials. These machines use a focused beam of light to melt, vaporize, or burn through materials, creating clean and accurate cuts. This article provides a comprehensive guide to laser cutting machine 3D models, covering their features, applications, benefits, and considerations.

Table of Content

- 1 Laser Cutting Machine 3D Model: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Features of Laser Cutting Machine 3D Models

- 1.3 Features of Laser Cutting Machine 3D Models

- 1.4 Applications of Laser Cutting Machine 3D Models

- 1.5 Benefits of Laser Cutting Machine 3D Models

- 1.6 Considerations for Selecting a Laser Cutting Machine 3D Model

- 1.7 Conclusion

- 1.8 FAQs

Features of Laser Cutting Machine 3D Models

- CO2 Laser: High-power laser source for cutting thick and hard materials

- Fiber Laser: Compact and energy-efficient laser source for precision cutting

2. Cutting Bed

- Single Table: Fixed cutting bed for simple operations

- Shuttle Table: Automated table that allows continuous loading and unloading

3. Axis System

Laser cutting machines have revolutionized the manufacturing industry, enabling precise and intricate cutting of various materials. These machines use a focused beam of light to melt, vaporize, or burn through materials, creating clean and accurate cuts. This article provides a comprehensive guide to laser cutting machine 3D models, covering their features, applications, benefits, and considerations.

- 3d Laser Cut Sticker 3D Laser Cut Stickers: Elevate Your Brand With Dimension And Impact

- 3d Laser Cut Fish 3D Laser Cut Fish: A Comprehensive Guide

- 3d Laser Cut Files Free 3D Laser Cut Files Free: Unleash Your Creativity

- 3d Laser Cut Animal 3D Laser Cut Animal: A Comprehensive Guide To Laser Cutting Animal Designs

- 3d Laser Cut Kit 3D Laser Cut Kit: Unleashing Precision And Creativity In Model Making

Features of Laser Cutting Machine 3D Models

1. Laser Source

- CO2 Laser: High-power laser source for cutting thick and hard materials

- Fiber Laser: Compact and energy-efficient laser source for precision cutting

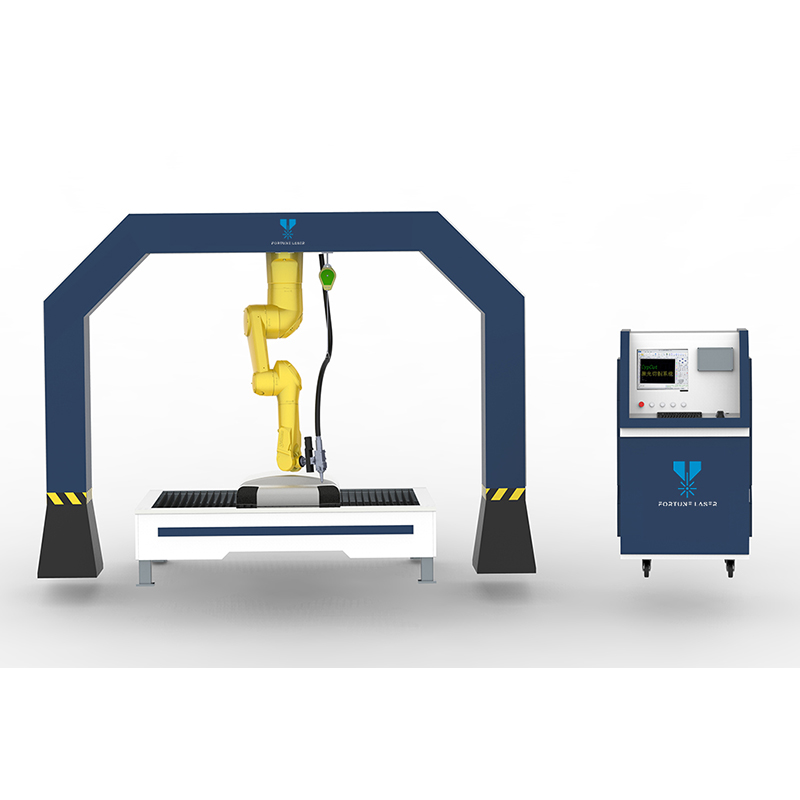

- 3-Axis System: X, Y, and Z axes for cutting 2D shapes

- 5-Axis System: Additional A and B axes for cutting 3D shapes

- User-friendly interface for designing and controlling cutting operations

- CAD/CAM compatibility for seamless integration with design software

- Enclosure with safety interlocks to prevent operator exposure to laser beam

- Exhaust system to remove fumes and debris

- Automotive: Cutting metal parts for vehicles

- Aerospace: Fabricating lightweight and complex aircraft components

- Electronics: Precision cutting of PCBs and other electronic components

- Medical: Creating medical devices and implants

- Jewelry: Intricate cutting of precious metals

- Precision and Accuracy: Laser cutting provides extremely precise and accurate cuts with minimal burrs

- Speed and Efficiency: Laser cutting is a high-speed process, reducing production time and costs

- Versatility: Laser cutting can handle a wide range of materials, including metals, plastics, and wood

- Reduced Waste: Laser cutting minimizes material waste, as it only cuts the necessary areas

- Automation: Automated cutting processes reduce labor requirements and increase productivity

- Material Thickness and Type: Consider the thickness and type of materials you need to cut

- Cutting Speed and Accuracy: Determine the desired cutting speed and accuracy requirements

- Work Area Size: Choose a machine with a work area that accommodates your cutting needs

- Budget: Set a budget and research machines that fit within your financial constraints

- Maintenance and Support: Consider the availability of maintenance and technical support services

4. Control Software

5. Safety Features

Applications of Laser Cutting Machine 3D Models

Laser cutting machines are widely used in various industries, including:

Benefits of Laser Cutting Machine 3D Models

Considerations for Selecting a Laser Cutting Machine 3D Model

Conclusion

Laser cutting machine 3D models offer a powerful solution for precise and efficient cutting of various materials. By understanding their features, applications, benefits, and considerations, manufacturers can select the right machine for their specific needs. Laser cutting technology continues to evolve, enabling new possibilities in manufacturing and design.

FAQs

Q: What is the difference between a 3-axis and a 5-axis laser cutting machine?

A: A 3-axis machine cuts 2D shapes, while a 5-axis machine can cut 3D shapes with additional rotational axes.

Q: Can laser cutting machines cut all types of materials?

A: Laser cutting machines can cut a wide range of materials, including metals, plastics, and wood. However, some materials may require specialized laser sources or cutting parameters.

Q: How do I ensure the safety of a laser cutting machine?

A: Laser cutting machines must have safety interlocks, an enclosure, and an exhaust system to protect operators from the laser beam and fumes.

Q: What is the cost of a laser cutting machine 3D model?

A: The cost of a laser cutting machine varies depending on its features, size, and manufacturer. Research different models and compare prices to find the best option for your budget.

Q: How do I maintain a laser cutting machine 3D model?

A: Regular maintenance is crucial for optimal performance. Follow manufacturer’s guidelines for cleaning, lubrication, and calibration.