Laser Cutting Wooden Box: A Comprehensive Guide

Introduction

Laser cutting, a revolutionary technology, has transformed the way we create wooden boxes, offering unparalleled precision, efficiency, and design flexibility. This article delves into the intricate details of laser cutting wooden boxes, exploring the process, benefits, materials, and applications.

Table of Content

- 1 Laser Cutting Wooden Box: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: The Process of Laser Cutting Wooden Boxes

- 1.3 H2: Benefits of Laser Cutting Wooden Boxes

- 1.4 H3: Materials for Laser Cutting Wooden Boxes

- 1.5 H4: Applications of Laser Cut Wooden Boxes

- 1.6 H1: The Process of Laser Cutting Wooden Boxes

- 1.7 H2: Benefits of Laser Cutting Wooden Boxes

- 1.8 H2: Conclusion

- 1.9 FAQs

H1: The Process of Laser Cutting Wooden Boxes

H2: Benefits of Laser Cutting Wooden Boxes

1. Precision and Accuracy: Laser cutting ensures unmatched precision, enabling the creation of complex designs and intricate patterns with high repeatability.

2. Design Flexibility: Laser cutting empowers designers with the freedom to explore unique and innovative designs, pushing the boundaries of creativity.

3. Efficiency and Speed: Compared to traditional cutting methods, laser cutting offers significantly faster production times, reducing labor costs and increasing throughput.

4. Material Versatility: Laser cutting is compatible with a wide range of wood types, including hardwoods, softwoods, and engineered woods, allowing for diverse applications.

H3: Materials for Laser Cutting Wooden Boxes

DOWNLOAD SVG FILES FOR LASER CUTTING

1. Hardwood: Known for its durability and strength, hardwood is ideal for high-end and decorative boxes. Examples include mahogany, oak, and walnut.

2. Softwood: Softwood is a more economical option, offering a softer texture and lighter weight. Pine, fir, and spruce are commonly used for laser cutting.

3. Engineered Wood: Engineered wood combines the strength of hardwood with the affordability of softwood, making it a versatile choice for various applications.

H4: Applications of Laser Cut Wooden Boxes

Laser cutting, a revolutionary technology, has transformed the way we create wooden boxes, offering unparalleled precision, efficiency, and design flexibility. This article delves into the intricate details of laser cutting wooden boxes, exploring the process, benefits, materials, and applications.

- Etsy Wooden Laser Cut Words H1: Elevate Your Home Decor With Etsy Wooden Laser Cut Words

- Wooden Laser Cut Projects Wooden Laser Cut Projects: A Comprehensive Guide For Beginners And Enthusiasts

- Wooden Laser Cut Car Wooden Laser Cut Car: A Detailed Guide To Customization, Design, And Assembly

- Fiber Laser Wood Fiber Laser Wood: A Comprehensive Guide

- Wooden Laser Cut Flowers H1: Wooden Laser Cut Flowers: A Guide To Crafting Enchanting Floral Decor

H1: The Process of Laser Cutting Wooden Boxes

Laser cutting involves directing a focused beam of light onto a wooden surface, vaporizing the material along its path. This process is controlled by a computer program that guides the laser, resulting in precise cuts and intricate designs.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Benefits of Laser Cutting Wooden Boxes

1. Precision and Accuracy: Laser cutting ensures unmatched precision, enabling the creation of complex designs and intricate patterns with high repeatability.

2. Design Flexibility: Laser cutting empowers designers with the freedom to explore unique and innovative designs, pushing the boundaries of creativity.

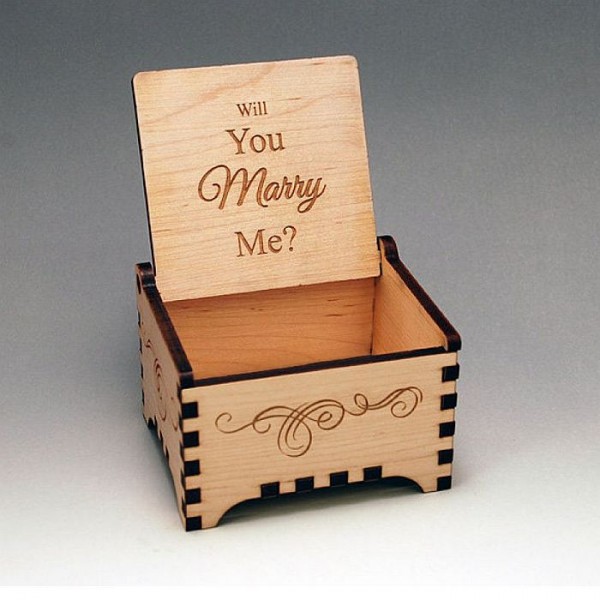

1. Jewelry Boxes: Laser cutting enables the creation of intricate and elegant jewelry boxes, showcasing the beauty of the contents within.

2. Gift Boxes: Laser cut wooden boxes add a touch of sophistication to gifts, providing a memorable and personalized touch.

3. Decorative Boxes: Laser cutting allows for the production of decorative boxes with unique patterns and designs, enhancing home décor and adding a touch of style.

4. Storage Boxes: Laser cut wooden boxes offer a practical and aesthetically pleasing solution for storing various items, from books to toys to collectibles.

H2: Conclusion

Laser cutting wooden boxes has revolutionized the industry, offering unparalleled precision, efficiency, and design flexibility. By leveraging the versatility of various wood types and the ingenuity of laser technology, we can create stunning and functional boxes that cater to a wide range of applications.

FAQs

1. What is the maximum thickness of wood that can be laser cut?

The maximum thickness of wood that can be laser cut depends on the laser’s power and the specific type of wood. Typically, laser cutters can cut wood up to a thickness of 1/4 inch.

2. What is the best type of wood for laser cutting?

Hardwoods, such as mahogany and oak, are ideal for laser cutting due to their durability and strength. Softwoods, like pine and fir, are also suitable for laser cutting but may require lower laser power settings.

3. Can laser cutting damage the wood?

Laser cutting can damage the wood if the laser power or speed is not set correctly. It is important to adjust the laser settings based on the type of wood and the desired cut quality.