Laser Wood Cutter Machine Cost: A Comprehensive Guide for Smart Investments

Introduction

The advent of laser wood cutter machines has revolutionized the woodworking industry, empowering businesses and hobbyists alike with unparalleled precision and efficiency. However, navigating the market for these machines can be daunting due to the wide range of models and pricing options. This comprehensive guide will provide you with an in-depth understanding of laser wood cutter machine costs, helping you make an informed decision that aligns with your specific needs and budget.

Table of Content

- 1 Laser Wood Cutter Machine Cost: A Comprehensive Guide for Smart Investments

- 1.1 Introduction

- 1.2 Factors Influencing Laser Wood Cutter Machine Cost

- 1.3 Types of Laser Wood Cutter Machines

- 1.4 Factors Influencing Laser Wood Cutter Machine Cost

- 1.5 Cost Range of Laser Wood Cutter Machines

- 1.6 Choosing the Right Machine for Your Needs

- 1.7 Maintenance and Operating Costs

- 1.8 Conclusion

- 1.9 FAQs

Factors Influencing Laser Wood Cutter Machine Cost

- Laser Power: The power of the laser, measured in watts, determines the thickness and types of materials that can be cut. Higher-powered lasers typically cost more.

- Bed Size: The size of the cutting bed determines the maximum size of materials that can be cut. Larger bed sizes command higher prices.

- Brand Reputation: Reputable brands with proven track records and customer support tend to charge more for their machines.

- Features and Accessories: Additional features such as automatic focus, air assist, and rotary attachments can increase the cost of the machine.

- Market Demand: The demand for specific models and features can influence pricing.

Types of Laser Wood Cutter Machines

There are two main types of laser wood cutter machines available:

- Laser Cut Out Wooden Hearts Laser Cut Out Wooden Hearts: A Timeless Expression Of Love And Creativity

- Wooden Laser Cutting Services Wooden Laser Cutting Services: Precision And Versatility For Your Woodworking Projects

- Wooden Laser Cut Christmas Decorations Wooden Laser Cut Christmas Decorations: A Festive Touch For Your Home

- Wooden Die Cut Wooden Die Cut: A Comprehensive Guide To Precision Cutting And Customization

- Lasered Wood Signs Lasered Wood Signs: An Artful And Versatile Decorative Solution

- Laser Power: The power of the laser, measured in watts, determines the thickness and types of materials that can be cut. Higher-powered lasers typically cost more.

- Bed Size: The size of the cutting bed determines the maximum size of materials that can be cut. Larger bed sizes command higher prices.

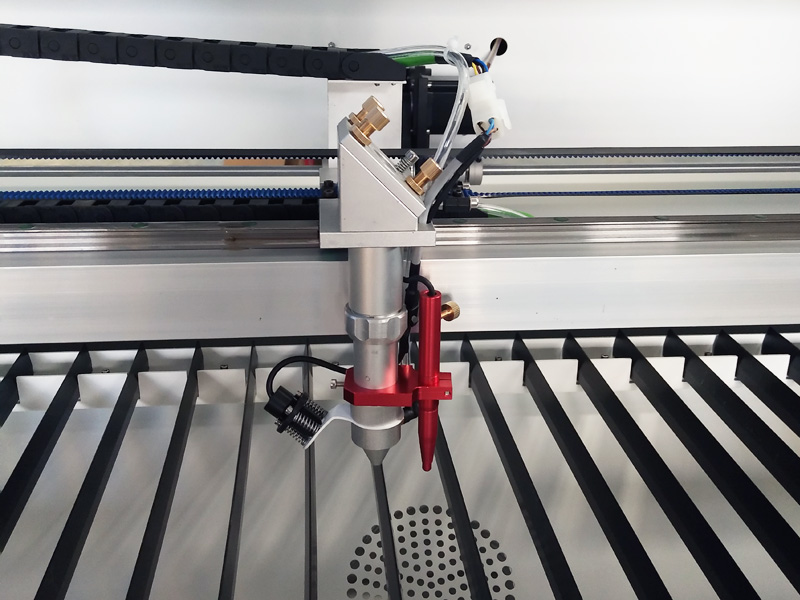

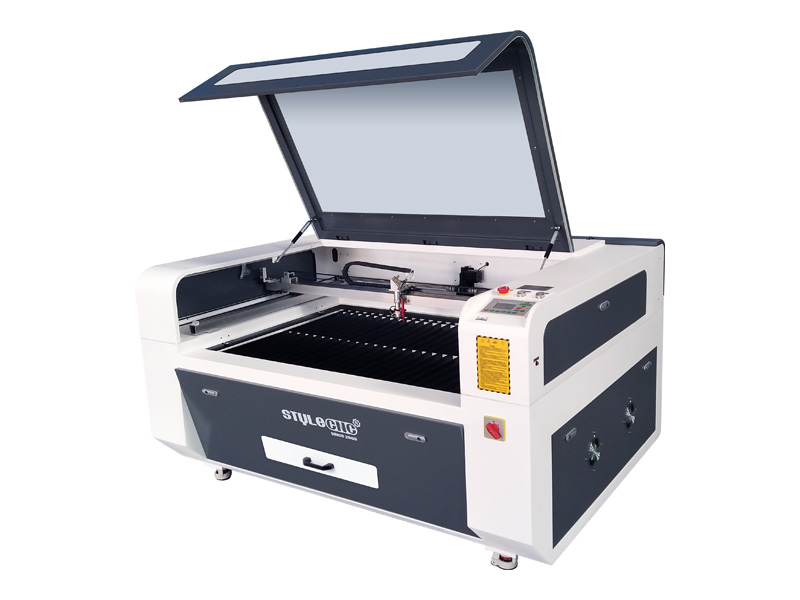

- CO2 Laser Machines: These machines use carbon dioxide gas to generate a laser beam. They are commonly used for cutting and engraving wood, acrylic, and other non-metallic materials.

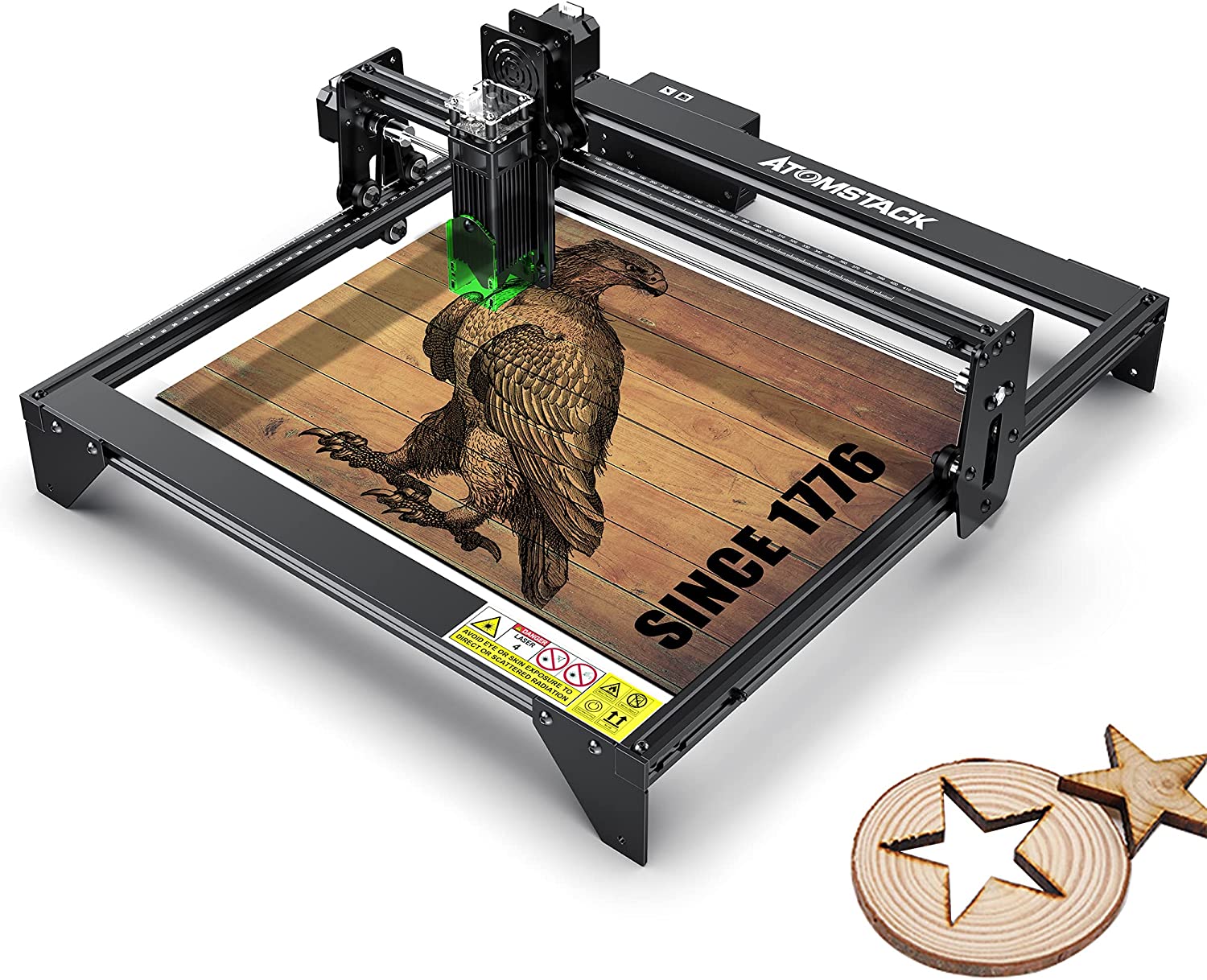

- Fiber Laser Machines: These machines use a fiber optic cable to deliver a laser beam. They are known for their high precision, speed, and ability to cut a wider range of materials, including metals.

- CO2 Laser Machines: Range from $2,000 to $20,000 for entry-level models to over $100,000 for high-end industrial machines.

- Fiber Laser Machines: Range from $10,000 to $50,000 for entry-level models to over $200,000 for high-power industrial machines.

- Intended Use: Determine the types of materials and projects you will be working on.

- Budget: Set a realistic budget that includes not only the machine cost but also maintenance and operating expenses.

- Features and Capabilities: Identify the features and capabilities that are essential for your specific needs.

- Customer Support: Look for a supplier that offers reliable customer support and technical assistance.

- Maintenance: Regular cleaning, calibration, and replacement of consumables are necessary to ensure optimal performance.

- Materials: The cost of materials such as wood, acrylic, or metal can vary depending on the project requirements.

- Electricity: Laser wood cutter machines consume electricity during operation, which can impact operating expenses.

The advent of laser wood cutter machines has revolutionized the woodworking industry, empowering businesses and hobbyists alike with unparalleled precision and efficiency. However, navigating the market for these machines can be daunting due to the wide range of models and pricing options. This comprehensive guide will provide you with an in-depth understanding of laser wood cutter machine costs, helping you make an informed decision that aligns with your specific needs and budget.

Factors Influencing Laser Wood Cutter Machine Cost

Several factors significantly impact the cost of laser wood cutter machines:

DOWNLOAD SVG FILES FOR LASER CUTTING

Fiber laser machines generally cost more than CO2 laser machines due to their advanced technology.

Cost Range of Laser Wood Cutter Machines

The cost of laser wood cutter machines can vary significantly depending on the factors discussed above. As a general guideline:

Choosing the Right Machine for Your Needs

To select the appropriate laser wood cutter machine, consider the following factors:

Maintenance and Operating Costs

In addition to the initial purchase price, laser wood cutter machines require ongoing maintenance and operating costs. These include:

Conclusion

Understanding the factors influencing laser wood cutter machine cost is crucial for making an informed investment. By carefully considering your needs, budget, and the available options, you can select the machine that best suits your requirements. Remember to factor in ongoing maintenance and operating costs to ensure a sustainable and cost-effective solution for your woodworking projects.

FAQs

Q: What is the best type of laser wood cutter machine for beginners?

A: Entry-level CO2 laser machines are a good option for beginners due to their lower cost and ease of use.

Q: Can laser wood cutter machines cut metal?

A: Fiber laser machines are capable of cutting metal, while CO2 laser machines are not.

Q: How often do laser wood cutter machines require maintenance?

A: Regular maintenance, such as cleaning and calibration, is recommended every 50-100 hours of operation.

Q: What is the lifespan of a laser wood cutter machine?

A: With proper maintenance, laser wood cutter machines can have a lifespan of up to 10 years or more.

Q: Can I use a laser wood cutter machine in a home environment?

A: Yes, small-scale laser wood cutter machines are suitable for home use. However, proper ventilation and safety precautions are essential.