Mazak 3D Laser Cutting: Revolutionizing Metal Fabrication

Introduction

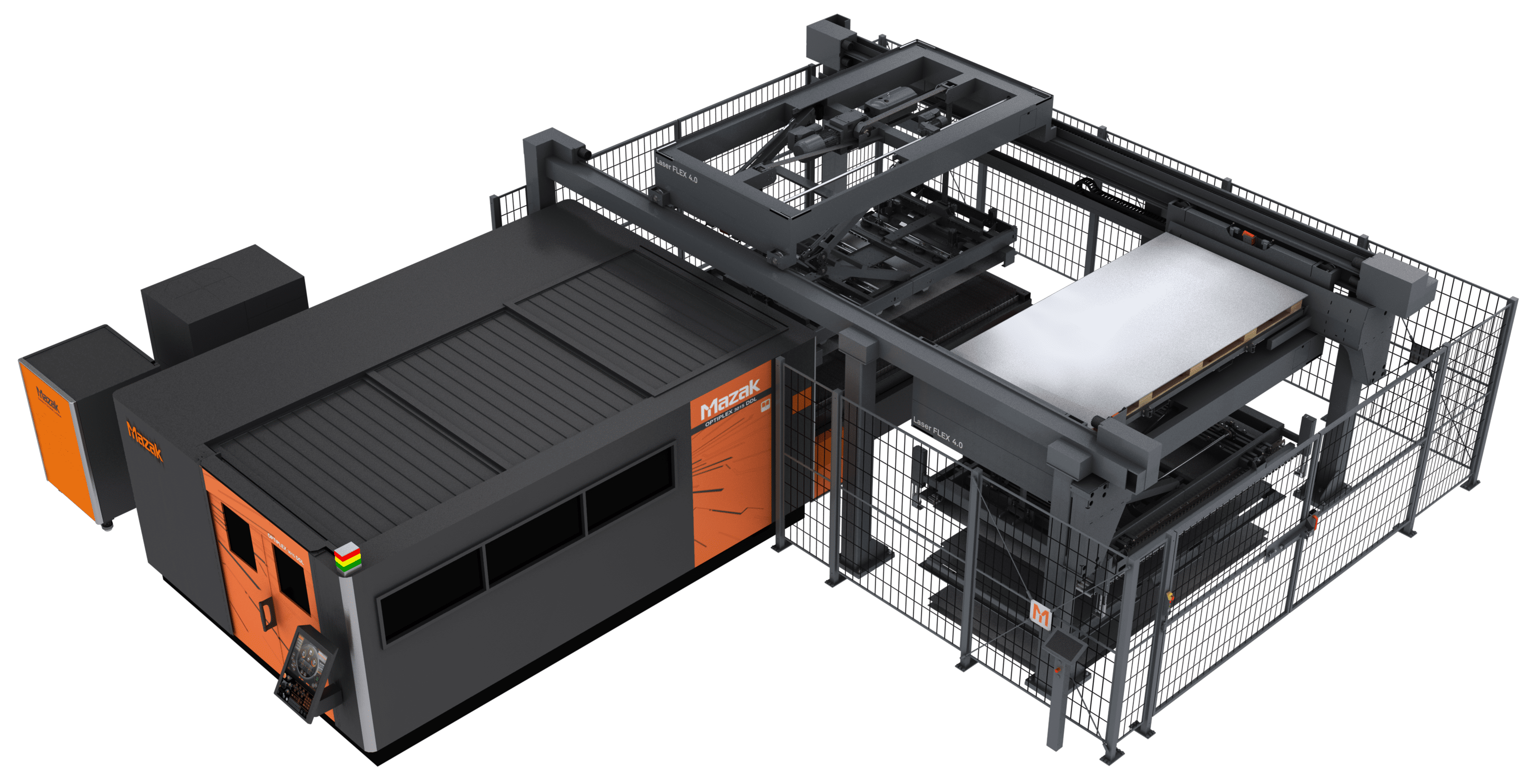

Mazak 3D Laser Cutting technology has emerged as a game-changer in the metal fabrication industry, offering unparalleled precision, speed, and versatility. With its ability to cut complex shapes and contours in three dimensions, Mazak 3D laser cutting machines empower manufacturers to produce intricate components with exceptional accuracy and efficiency.

Table of Content

- 1 Mazak 3D Laser Cutting: Revolutionizing Metal Fabrication

- 1.1 H2: Increased Speed and Efficiency

- 1.2 H2: Enhanced Versatility

- 1.3 H2: Cost Savings and Reduced Waste

- 1.4 H2: Automotive Industry

- 1.5 H2: Unmatched Precision and Accuracy

- 1.6 H2: Increased Speed and Efficiency

- 1.7 H2: Aerospace Industry

- 1.8 H2: Medical Industry

H1: The Advantages of Mazak 3D Laser Cutting

Mazak 3D laser cutting systems utilize advanced laser technology to achieve exceptional precision and accuracy. The laser beam, guided by sophisticated software, can precisely follow complex contours and cut intricate shapes with minimal tolerance variations. This precision enables manufacturers to produce high-quality components that meet demanding specifications.

H2: Increased Speed and Efficiency

Compared to traditional cutting methods, Mazak 3D laser cutting offers significantly faster cutting speeds. The high-power laser beam rapidly melts and vaporizes the metal, resulting in reduced cycle times and increased productivity. This speed advantage allows manufacturers to meet tight production deadlines and optimize their operations.

H2: Enhanced Versatility

Mazak 3D laser cutting machines are highly versatile and can process a wide range of materials, including steel, stainless steel, aluminum, and titanium. This versatility enables manufacturers to produce a diverse array of components for various industries, such as automotive, aerospace, and medical.

H2: Cost Savings and Reduced Waste

The precision and efficiency of Mazak 3D laser cutting lead to cost savings and reduced waste. By minimizing material waste and reducing the need for rework, manufacturers can optimize their material usage and lower production costs.

H1: Applications of Mazak 3D Laser Cutting

H2: Automotive Industry

Mazak 3D laser cutting is widely used in the automotive industry for producing complex components such as chassis, body panels, and exhaust systems. The high precision and speed of the technology enable manufacturers to meet the demanding quality and production requirements of the industry.

Mazak 3D Laser Cutting technology has emerged as a game-changer in the metal fabrication industry, offering unparalleled precision, speed, and versatility. With its ability to cut complex shapes and contours in three dimensions, Mazak 3D laser cutting machines empower manufacturers to produce intricate components with exceptional accuracy and efficiency.

- Laser Cutting Ender 3 Laser Cutting Ender 3: A Comprehensive Guide To Enhancing Your 3D Printer’s Capabilities

- 3d Printers And Laser Cutters 3D Printers And Laser Cutters: A Comprehensive Guide

- 3d Printing And Laser Cutting 3D Printing And Laser Cutting: A Comprehensive Guide

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide To Precision Fabrication

- 3d Laser Cutting Metal 3D Laser Cutting Metal: A Comprehensive Guide

H1: The Advantages of Mazak 3D Laser Cutting

H2: Unmatched Precision and Accuracy

Mazak 3D laser cutting systems utilize advanced laser technology to achieve exceptional precision and accuracy. The laser beam, guided by sophisticated software, can precisely follow complex contours and cut intricate shapes with minimal tolerance variations. This precision enables manufacturers to produce high-quality components that meet demanding specifications.

H2: Increased Speed and Efficiency

Compared to traditional cutting methods, Mazak 3D laser cutting offers significantly faster cutting speeds. The high-power laser beam rapidly melts and vaporizes the metal, resulting in reduced cycle times and increased productivity. This speed advantage allows manufacturers to meet tight production deadlines and optimize their operations.

H2: Aerospace Industry

In the aerospace industry, Mazak 3D laser cutting is essential for producing lightweight and durable aircraft components. The technology allows manufacturers to cut intricate shapes and contours with precision, meeting the stringent specifications of the industry.

H2: Medical Industry

Mazak 3D laser cutting finds applications in the medical industry, where it is used to produce surgical instruments, medical implants, and other medical devices. The technology enables manufacturers to create complex geometries and precise cuts, ensuring the accuracy and reliability of medical equipment.

H1: Conclusion

Mazak 3D Laser Cutting technology has revolutionized metal fabrication by offering unparalleled precision, speed, versatility, and cost savings. Manufacturers across various industries can leverage this advanced technology to produce complex components with exceptional quality and efficiency. As the technology continues to evolve, it is expected to further enhance productivity and innovation in the metal fabrication sector.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting cuts flat sheet metal, while 3D laser cutting can cut complex shapes and contours in three dimensions.

Q: What materials can be cut with Mazak 3D laser cutting?

A: Mazak 3D laser cutting machines can process a wide range of materials, including steel, stainless steel, aluminum, and titanium.

Q: How does Mazak 3D laser cutting ensure precision?

A: Mazak 3D laser cutting systems utilize advanced laser technology and sophisticated software to achieve exceptional precision and accuracy, ensuring minimal tolerance variations.

Q: Is Mazak 3D laser cutting suitable for high-volume production?

A: Yes, Mazak 3D laser cutting offers high-speed cutting capabilities, making it suitable for high-volume production environments where efficiency is crucial.

Q: How does Mazak 3D laser cutting reduce waste?

A: The precision and accuracy of Mazak 3D laser cutting minimize material waste and reduce the need for rework, leading to cost savings for manufacturers.