Order Laser Cut Wood: A Comprehensive Guide to Precision and Customization

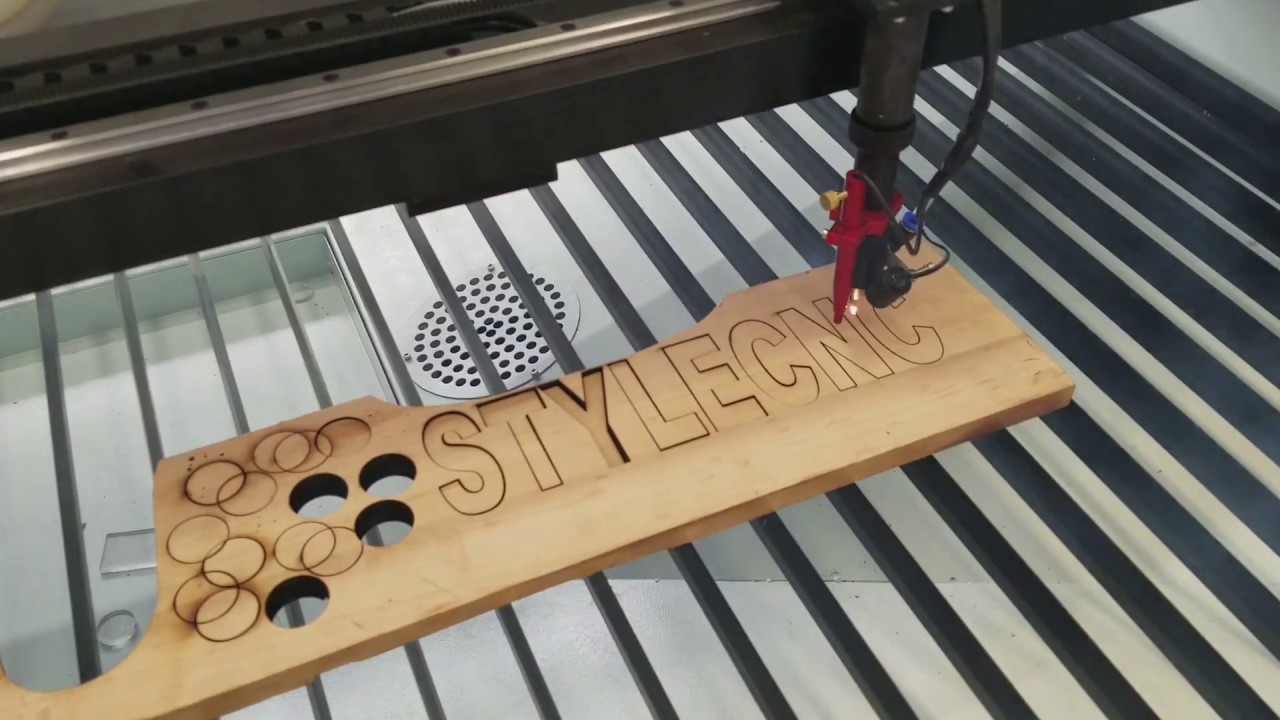

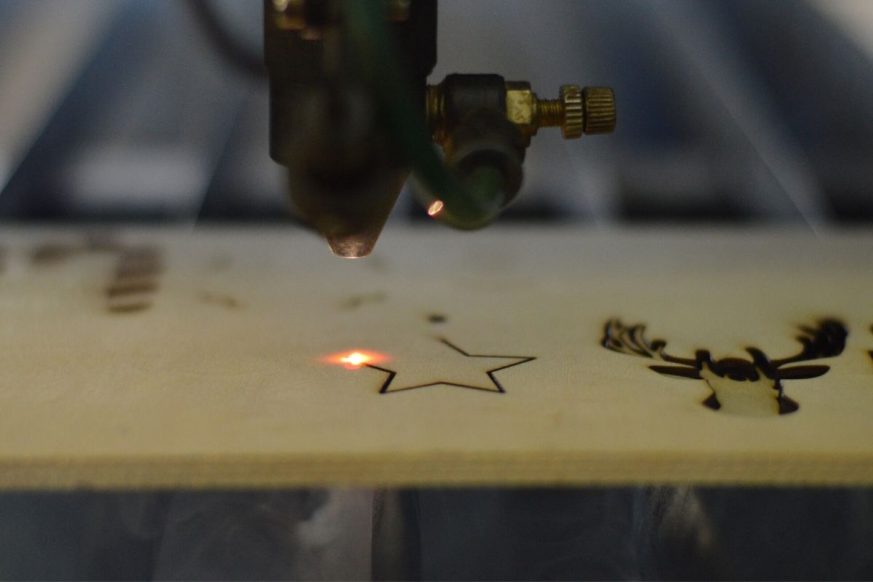

Laser cutting has revolutionized the woodworking industry, offering unparalleled precision, efficiency, and customization. Whether you’re a hobbyist, a small business owner, or a large-scale manufacturer, ordering laser cut wood can elevate your projects to new heights.

Benefits of Laser Cutting Wood

Table of Content

- 1 Order Laser Cut Wood: A Comprehensive Guide to Precision and Customization

- 1.1 Benefits of Laser Cutting Wood

- 1.2 Choosing a Laser Cutting Service

- 1.3 Benefits of Laser Cutting Wood

- 1.4 Preparing Your Design

- 1.5 Ordering Laser Cut Wood

- 1.6 Receiving and Using Laser Cut Wood

- 1.7 FAQs

- 1.8 Conclusion

- Speed and Efficiency: Laser cutters operate at high speeds, significantly reducing production time compared to traditional methods.

- Customization: Laser cutting allows for the creation of unique and personalized designs that would be difficult or impossible to achieve with other methods.

- Versatility: Laser cutters can process a wide range of wood species, including hardwoods, softwoods, and engineered wood products.

- Clean and Precise Cuts: Laser cutting produces clean and precise cuts with minimal burring or charring, ensuring a high-quality finish.

Choosing a Laser Cutting Service

DOWNLOAD SVG FILES FOR LASER CUTTING

Selecting the right laser cutting service is crucial for optimal results. Consider the following factors:

- Capabilities: Ensure the service can handle the thickness and size of your wood and meet your precision requirements.

- Materials: Verify that the service offers the specific wood species you need.

- Custom Cut Wood Custom Cut Wood: Precision And Perfection For Your Projects

- Laser Etching Wood Laser Etching Wood: A Comprehensive Guide To Precision And Creativity

- Best Wood Laser Engraver Best Wood Laser Engraver: A Comprehensive Guide To Choosing The Perfect Machine

- Best Laser Wood Engraver Best Laser Wood Engraver: A Comprehensive Guide For Precision And Creativity

- Wood Laser Cutting Near Me Wood Laser Cutting Near Me: A Comprehensive Guide To Finding The Best Services

- Precision and Accuracy: Laser cutting utilizes a highly focused laser beam to etch or cut intricate designs with unmatched precision.

- Speed and Efficiency: Laser cutters operate at high speeds, significantly reducing production time compared to traditional methods.

- Customization: Laser cutting allows for the creation of unique and personalized designs that would be difficult or impossible to achieve with other methods.

- Versatility: Laser cutters can process a wide range of wood species, including hardwoods, softwoods, and engineered wood products.

- Experience: Opt for a service with a proven track record and positive customer reviews.

- Pricing: Compare pricing from different services to find the best value for your needs.

- Turnaround Time: Consider the service’s turnaround time to ensure it aligns with your project deadlines.

- File Format: Save your design in a compatible file format, such as DXF, DWG, or AI.

- Scale: Ensure your design is scaled correctly to the desired size.

- Line Thickness: Use appropriate line thicknesses for laser cutting.

- Curves and Corners: Smooth out curves and avoid sharp corners to prevent burn marks.

- Test Cut: If possible, request a test cut to verify the accuracy and quality of the results.

- Contact the Service: Reach out to the chosen laser cutting service and provide your design file.

- Specify Materials: Indicate the type and thickness of wood you require.

- Provide Dimensions: Specify the dimensions of the cut pieces.

- Set Quantity: Determine the quantity of pieces you need.

- Confirm Turnaround Time: Agree on the expected turnaround time.

- Finalize Order: Submit your order and make the necessary payment.

- Sanding: Lightly sand the edges to remove any burrs or sharp edges.

- Finishing: Apply a suitable finish, such as stain, paint, or varnish, to protect and enhance the wood’s appearance.

- Assembly: If your design requires assembly, follow the instructions carefully.

- Storage: Store laser cut wood in a dry and well-ventilated area to prevent warping or damage.

Benefits of Laser Cutting Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Preparing Your Design

To ensure the best possible laser cutting results, it’s essential to prepare your design properly.

Ordering Laser Cut Wood

Once your design is ready, follow these steps to order laser cut wood:

Receiving and Using Laser Cut Wood

Upon receiving your laser cut wood, carefully inspect it for any imperfections or discrepancies. Follow these tips for optimal use:

FAQs

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness of wood that can be laser cut varies depending on the laser cutter’s capabilities. Generally, most laser cutters can handle wood up to 1 inch in thickness.

Q: How much does laser cutting wood cost?

A: The cost of laser cutting wood varies based on factors such as the size, complexity, and quantity of the cut pieces, as well as the laser cutting service’s pricing.

Q: Can laser cutting wood produce fumes?

A: Yes, laser cutting wood produces fumes due to the vaporization of wood particles. Proper ventilation is necessary to ensure a safe working environment.

Q: How long does it take to laser cut wood?

A: The cutting time depends on the size, complexity, and thickness of the wood. Small and simple cuts can be completed in a matter of minutes, while larger and more intricate designs may take several hours.

Q: Can laser cutting wood be used for outdoor applications?

A: While laser cutting wood is suitable for some outdoor applications, it’s important to use weather-resistant wood species and apply appropriate protective finishes to ensure durability.

Conclusion

Laser cutting wood offers a wealth of benefits, enabling the creation of precise, customized, and high-quality wood products. By choosing a reputable laser cutting service, preparing your design properly, and following best practices for receiving and using laser cut wood, you can unlock the full potential of this innovative technology and elevate your woodworking projects to the next level.