Sculpteo Laser Cutting: A Comprehensive Guide to Precision Manufacturing

Laser cutting has revolutionized the manufacturing industry, providing businesses with a versatile and efficient method for creating intricate designs and cutting complex materials. Sculpteo, a leading online 3D printing and manufacturing platform, offers a state-of-the-art laser cutting service that empowers designers, engineers, and makers to bring their ideas to life with unparalleled precision and speed.

H1: Benefits of Sculpteo Laser Cutting

Table of Content

- 1 Sculpteo Laser Cutting: A Comprehensive Guide to Precision Manufacturing

- 1.1 H1: Benefits of Sculpteo Laser Cutting

- 1.2 H2: Materials Suitable for Laser Cutting

- 1.3 H1: Benefits of Sculpteo Laser Cutting

- 1.4 H3: Laser Cutting Process at Sculpteo

- 1.5 H4: Applications of Sculpteo Laser Cutting

- 1.6 H5: Advantages of Choosing Sculpteo for Laser Cutting

- 1.7 H6: Conclusion

- 1.8 FAQs

Sculpteo’s laser cutting service offers numerous advantages for businesses of all sizes:

H2: Materials Suitable for Laser Cutting

Sculpteo’s laser cutting service supports a variety of materials, each with unique properties and applications:

- Metals: Stainless steel, aluminum, brass, and copper are commonly used metals for laser cutting, offering durability, strength, and corrosion resistance.

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide

- Anycubic Mega Pro Laser Cutting Anycubic Mega Pro: A Comprehensive Guide To Laser Cutting Precision

- 3d Cnc Cutting Design 3D CNC Cutting Design: A Comprehensive Guide

- Afinia Emblaser 2 Afinia Emblaser 2: A Comprehensive Guide To Laser Engraving And Cutting

- Precision and Accuracy: Laser cutters utilize highly focused beams of light to cut materials with extreme precision, ensuring consistent and accurate results even for intricate designs.

- Versatility: Laser cutting can handle a wide range of materials, including metals, plastics, wood, and fabrics, making it suitable for diverse applications.

- Efficiency: Laser cutters operate at high speeds, significantly reducing production time and increasing productivity.

- Plastics: Acrylic, polycarbonate, and ABS are popular plastic materials for laser cutting, providing transparency, flexibility, and chemical resistance.

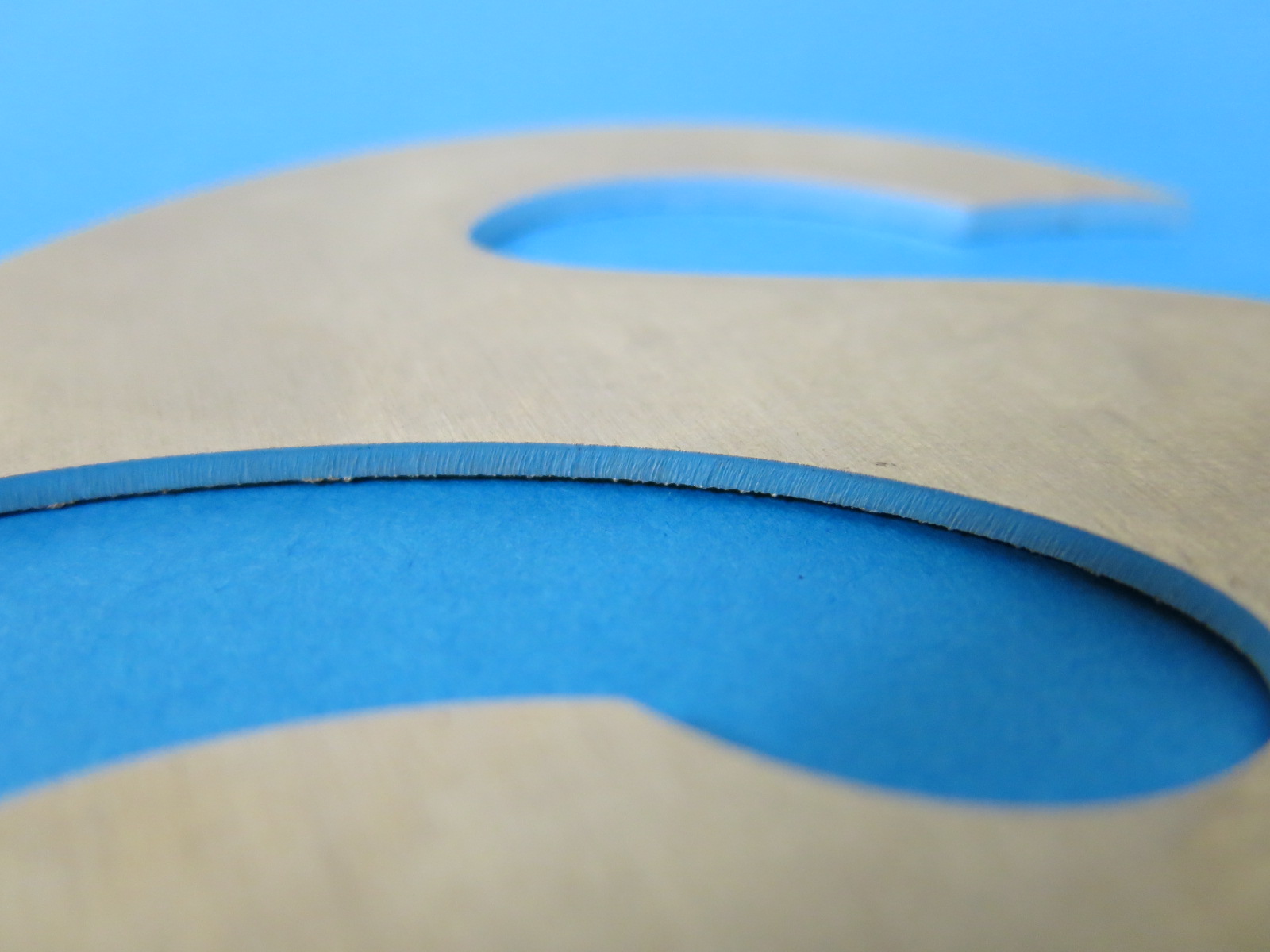

- Wood: Plywood, MDF, and hardwood are suitable for laser cutting, offering natural aesthetics and versatility.

- Fabrics: Leather, felt, and textiles can be laser cut for applications such as garment manufacturing, interior design, and prototyping.

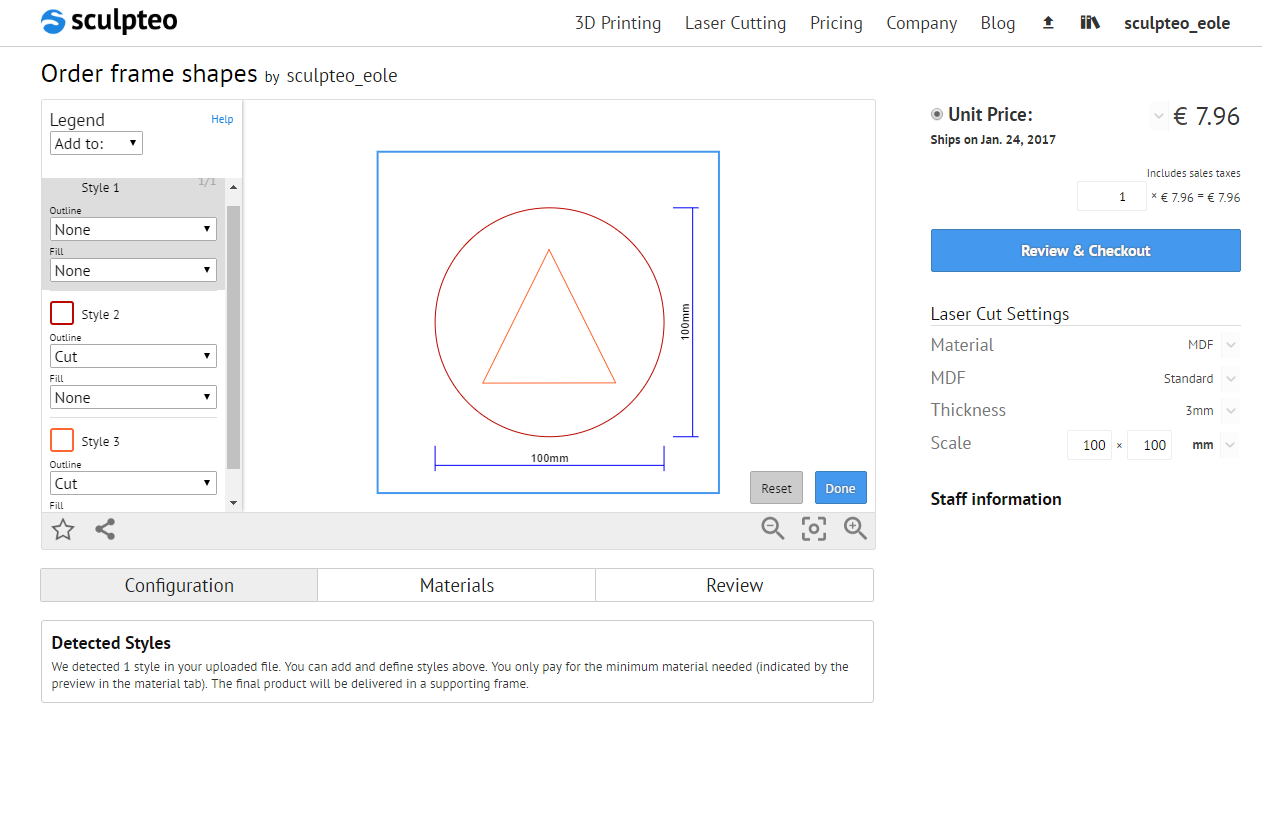

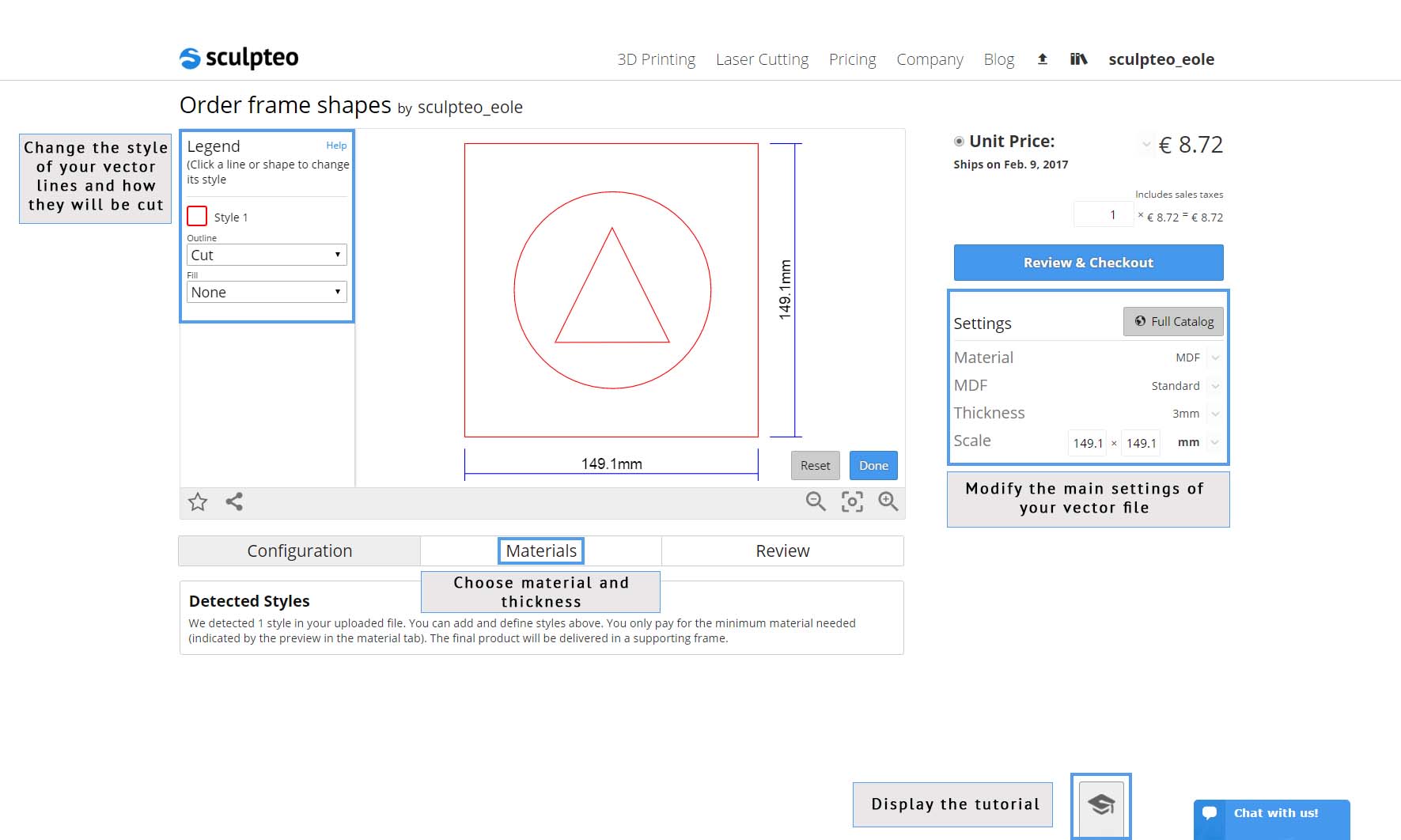

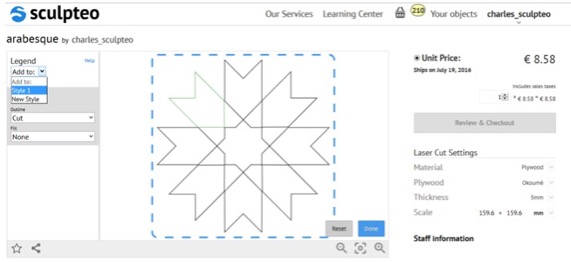

- File Preparation: Customers upload their 3D or 2D design files in standard formats such as STL, STEP, or DXF.

- Material Selection: The appropriate material is selected based on the project requirements and design specifications.

- Laser Cutting: The laser cutter precisely cuts the material according to the design, creating intricate patterns and shapes.

- Post-Processing: Depending on the material and application, post-processing steps such as deburring, polishing, or painting may be required.

- Industrial Manufacturing: Precision parts, prototypes, and custom components for automotive, aerospace, and medical devices.

- Architecture and Construction: Facade panels, decorative elements, and architectural models.

- Design and Art: Jewelry, sculptures, and home decor items with intricate designs.

- Signage and Displays: Custom signs, promotional displays, and marketing materials.

- Product Development: Prototyping, testing, and production of new products with complex geometries.

- Online Platform: Convenient and accessible online platform for ordering and managing laser cutting projects.

- Expertise and Support: Team of experts providing guidance and support throughout the process.

- Quality Control: Rigorous quality control measures ensure the highest standards of accuracy and precision.

- Fast Turnaround: Efficient production processes and flexible delivery options to meet project deadlines.

- Sustainable Practices: Commitment to sustainable manufacturing practices and reducing environmental impact.

H1: Benefits of Sculpteo Laser Cutting

Sculpteo’s laser cutting service offers numerous advantages for businesses of all sizes:

H3: Laser Cutting Process at Sculpteo

Sculpteo’s laser cutting process involves several key steps:

H4: Applications of Sculpteo Laser Cutting

Laser cutting has a wide range of applications across various industries:

H5: Advantages of Choosing Sculpteo for Laser Cutting

Partnering with Sculpteo for laser cutting offers several advantages:

H6: Conclusion

Sculpteo Laser Cutting is a powerful tool that empowers businesses and individuals to create innovative and precise products. Its versatility, efficiency, and cost-effectiveness make it an ideal solution for a wide range of applications. By partnering with Sculpteo, customers can leverage the latest laser cutting technology and benefit from exceptional quality, fast turnaround, and industry-leading support.

FAQs

Q: What is the minimum order quantity for laser cutting?

A: Sculpteo offers flexible production options, with no minimum order quantity required.

Q: Can Sculpteo handle complex designs with tight tolerances?

A: Yes, Sculpteo’s laser cutters are highly precise and can handle intricate designs with tolerances as low as ±0.05mm.

Q: What file formats does Sculpteo accept for laser cutting?

A: Sculpteo supports industry-standard file formats such as STL, STEP, and DXF.

Q: How long does it take to receive my laser-cut parts?

A: Production time varies depending on the project complexity and material selection. Sculpteo provides flexible delivery options to meet customer deadlines.

Q: What post-processing options are available for laser-cut parts?

A: Sculpteo offers various post-processing services, including deburring, polishing, painting, and anodizing.