Simple 3D Laser Cut: A Comprehensive Guide

Introduction

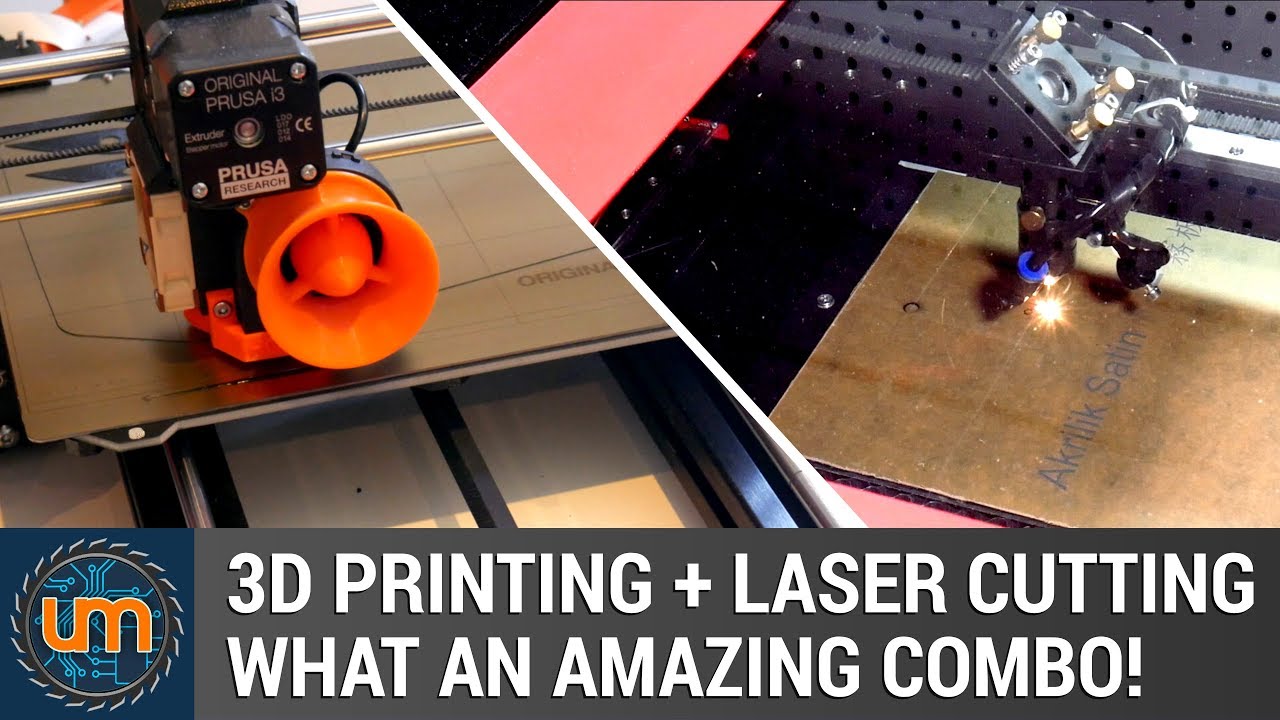

3D laser cutting is a versatile manufacturing technique that offers precision, speed, and design flexibility. With its ability to create complex shapes and intricate details from a wide range of materials, 3D laser cutting has become an indispensable tool in various industries, including automotive, aerospace, medical, and consumer electronics. This article provides a comprehensive guide to simple 3D laser cutting, covering its principles, applications, and best practices.

Table of Content

- 1 Simple 3D Laser Cut: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Principles of 3D Laser Cutting

- 1.3 Materials for 3D Laser Cutting

- 1.4 Applications of 3D Laser Cutting

- 1.5 Principles of 3D Laser Cutting

- 1.6 Materials for 3D Laser Cutting

- 1.7 Best Practices for 3D Laser Cutting

- 1.8 Advantages of 3D Laser Cutting

- 1.9 Limitations of 3D Laser Cutting

- 1.10 Conclusion

- 1.11 FAQs

Principles of 3D Laser Cutting

Materials for 3D Laser Cutting

3D laser cutting can be performed on a wide range of materials, including:

- Metals: Steel, stainless steel, aluminum, titanium

- Plastics: Acrylic, polycarbonate, polyethylene

- Wood: Plywood, MDF, hardwoods

- Composites: Carbon fiber, fiberglass

- Ceramics: Glass, porcelain

Applications of 3D Laser Cutting

3D laser cutting is a versatile manufacturing technique that offers precision, speed, and design flexibility. With its ability to create complex shapes and intricate details from a wide range of materials, 3D laser cutting has become an indispensable tool in various industries, including automotive, aerospace, medical, and consumer electronics. This article provides a comprehensive guide to simple 3D laser cutting, covering its principles, applications, and best practices.

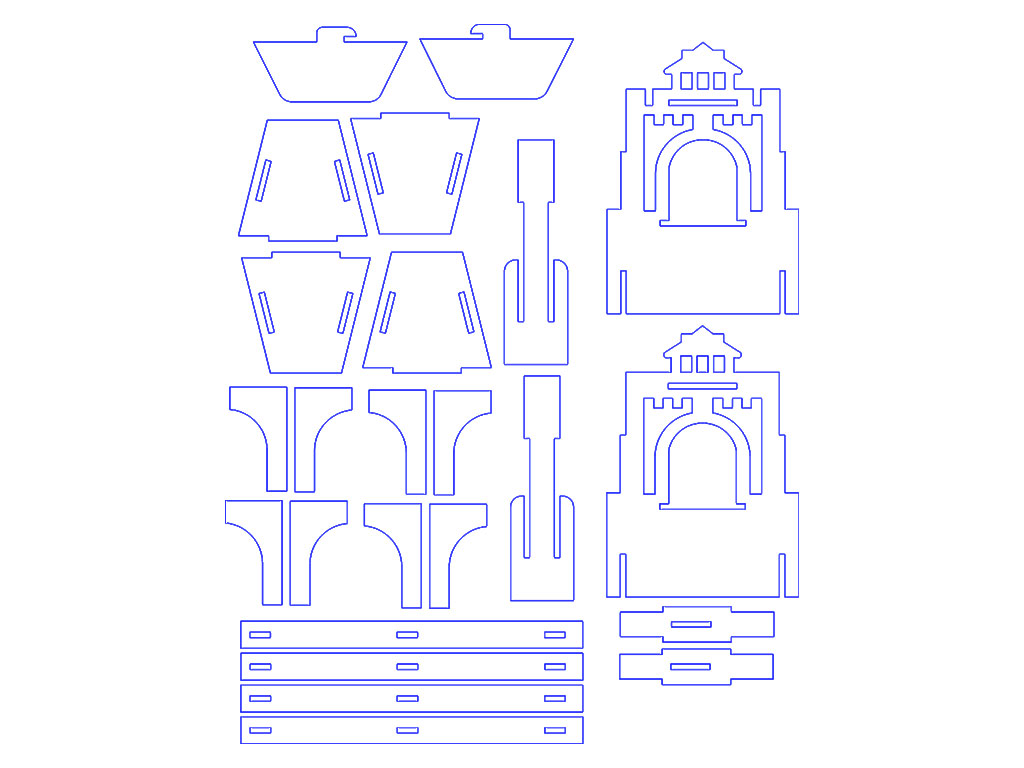

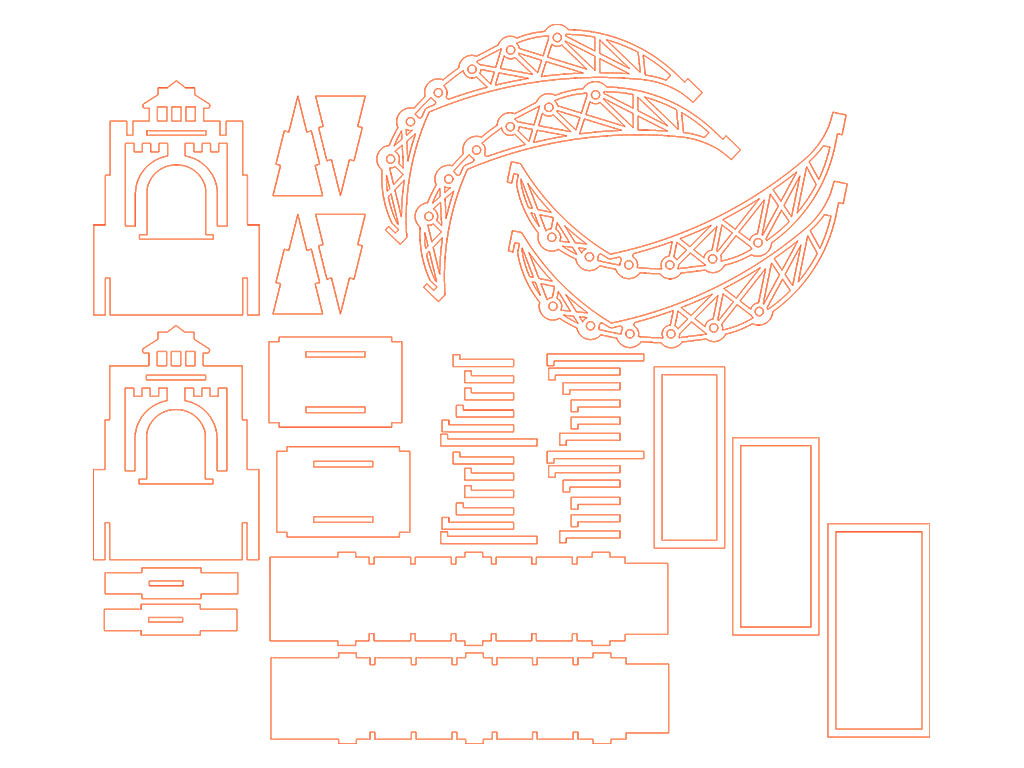

- Laser Cut Plan Puzzle 3d Gratuit Laser Cut Plan Puzzle 3d Gratuit: A Comprehensive Guide To Free Laser-Cut Puzzle Plans

- 3d Laser Cut Acrylic Letters 3D Laser Cut Acrylic Letters: A Comprehensive Guide

- Laser Cut 3d Model Files Laser Cut 3D Model Files: A Comprehensive Guide

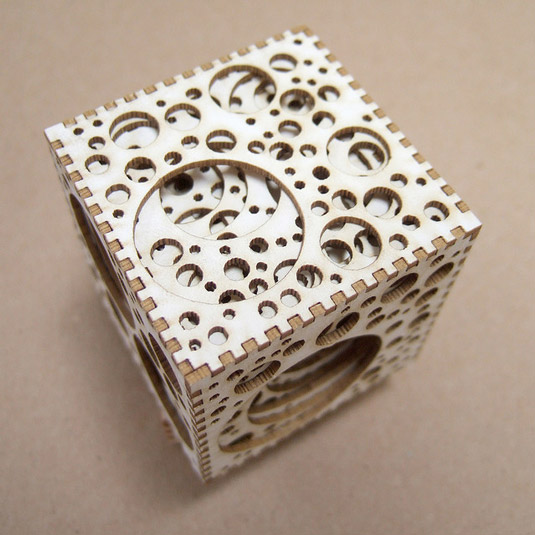

- 3d Laser Cut Crystal Cubes 3D Laser Cut Crystal Cubes: The Ultimate Guide To Captivating Decor And Personalized Gifts

- 3d Laser Cutter Projects 3D Laser Cutter Projects: Unleashing Creativity And Precision

Principles of 3D Laser Cutting

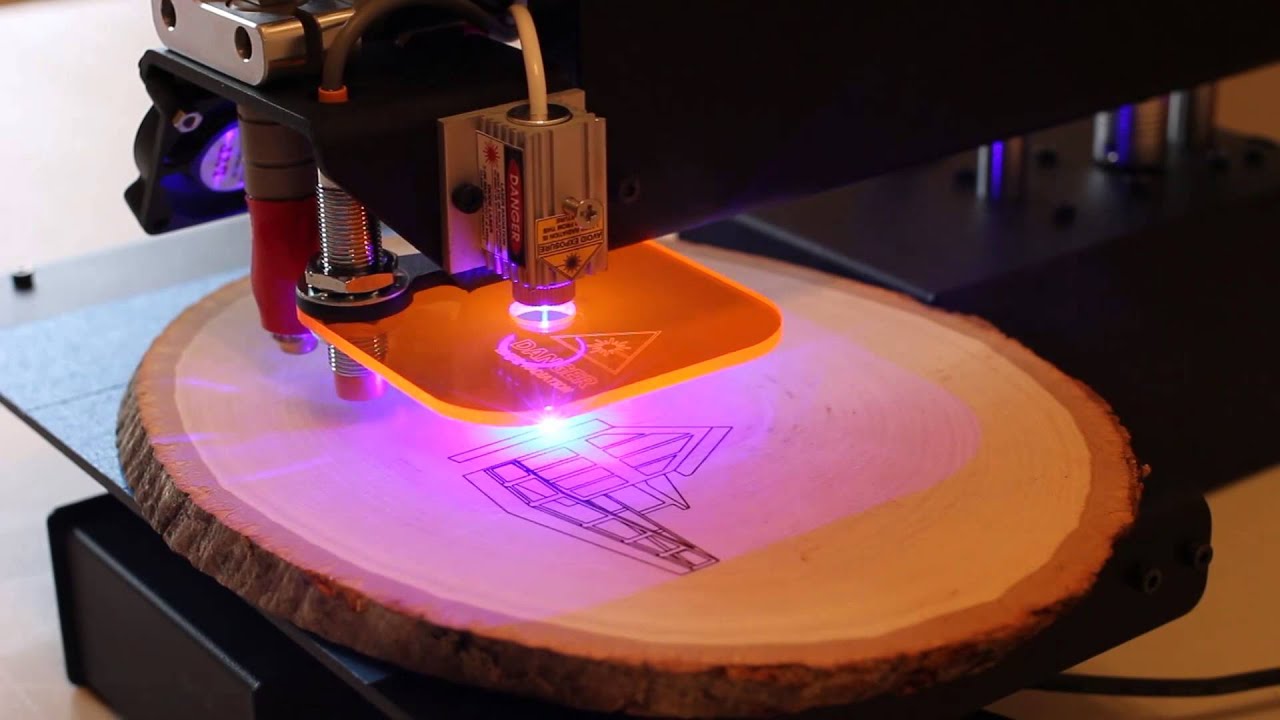

3D laser cutting involves directing a highly focused laser beam onto a workpiece, melting or vaporizing the material and removing it layer by layer. The laser beam is controlled by a computer-aided design (CAD) file, which defines the desired shape and dimensions of the cut. The laser’s power, wavelength, and pulse duration are carefully calibrated to optimize the cutting process for specific materials and applications.

Materials for 3D Laser Cutting

3D laser cutting can be performed on a wide range of materials, including:

- Automotive: Vehicle parts, interior trim, exhaust systems

- Aerospace: Aircraft components, engine parts, satellite structures

- Medical: Surgical instruments, implants, prosthetics

- Consumer Electronics: Smartphone cases, laptop chassis, gaming consoles

- Industrial: Machinery components, tooling, molds

- Use high-quality materials: Choose materials with consistent thickness and density to avoid imperfections during cutting.

- Optimize laser parameters: Calibrate laser power, wavelength, and pulse duration based on the material and desired cut quality.

- Proper ventilation: Laser cutting generates fumes and debris; ensure adequate ventilation to maintain a safe working environment.

- Use proper safety equipment: Wear appropriate personal protective equipment, including laser safety glasses and gloves.

- Maintain laser equipment: Regularly service and maintain laser equipment to prevent breakdowns and ensure optimal performance.

- Precision and Accuracy: Laser cutting provides exceptional precision and accuracy, enabling the creation of complex shapes with tight tolerances.

- Speed and Efficiency: Laser cutting is a fast and efficient process, reducing production time and increasing productivity.

- Design Flexibility: 3D laser cutting allows for the production of intricate designs and geometries that are difficult or impossible to achieve with traditional manufacturing methods.

- Material Versatility: Laser cutting can be performed on a wide range of materials, offering design and application flexibility.

- Cost-effectiveness: Laser cutting can be cost-effective for both prototyping and mass production, especially for small-batch or custom orders.

- Material Thickness: Laser cutting is limited by the thickness of the material that can be cut; thicker materials may require multiple passes or specialized equipment.

- Heat-Affected Zone: Laser cutting can create a heat-affected zone (HAZ) around the cut edge, which may affect the material’s properties and require post-processing.

- Fume Generation: Laser cutting generates fumes and debris, requiring proper ventilation to ensure a safe working environment.

- Equipment Cost: Laser cutting equipment can be expensive, especially for high-power systems or large-format machines.

- Maintenance and Expertise: Laser cutting equipment requires regular maintenance and technical expertise to ensure optimal performance.

3D laser cutting is used in numerous applications across various industries:

Best Practices for 3D Laser Cutting

To ensure optimal results and minimize potential issues, follow these best practices for 3D laser cutting:

Advantages of 3D Laser Cutting

Limitations of 3D Laser Cutting

Conclusion

3D laser cutting is a powerful manufacturing technique that offers precision, speed, and design flexibility for a wide range of applications. By following best practices and understanding its advantages and limitations, manufacturers can leverage 3D laser cutting to create innovative products and enhance their production processes.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting involves cutting flat materials, while 3D laser cutting enables the creation of three-dimensional shapes by cutting and stacking multiple layers of material.

Q: What materials can be laser cut in 3D?

A: 3D laser cutting can be performed on a wide range of materials, including metals, plastics, wood, composites, and ceramics.

Q: What are the advantages of 3D laser cutting?

A: 3D laser cutting offers precision, speed, design flexibility, material versatility, and cost-effectiveness.

Q: What are the limitations of 3D laser cutting?

A: 3D laser cutting is limited by material thickness, heat-affected zone, fume generation, equipment cost, and maintenance requirements.

Q: How can I ensure the quality of 3D laser cut parts?

A: Use high-quality materials, optimize laser parameters, ensure proper ventilation, use proper safety equipment, and maintain laser equipment regularly.

_Ha2aI1A.jpg)