Small Wood Laser Cutter Machine: A Comprehensive Guide

Introduction

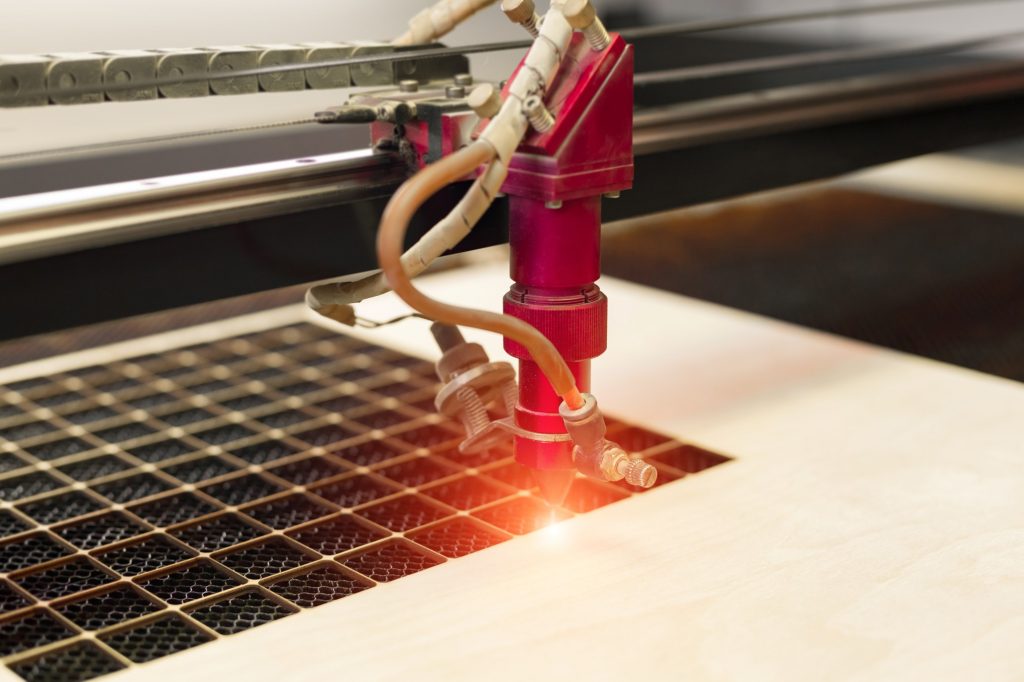

Small wood laser cutter machines have revolutionized the woodworking industry, enabling hobbyists and professionals alike to create intricate designs and precise cuts with ease. These compact machines offer a versatile and cost-effective solution for cutting, engraving, and marking a wide range of wood materials. This comprehensive guide will delve into the features, benefits, and applications of small wood laser cutter machines, providing valuable insights for potential users.

Table of Content

- 1 Small Wood Laser Cutter Machine: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Key Features of Small Wood Laser Cutter Machines

- 1.2.1 2. Work Area

- 1.2.2 3. Cutting and Engraving Speed

- 1.2.3 4. Software and Connectivity

- 1.3 Benefits of Small Wood Laser Cutter Machines

- 1.3.4 1. Precision and Accuracy

- 1.4 Key Features of Small Wood Laser Cutter Machines

- 1.4.5 1. Laser Power and Wavelength

- 1.4.6 2. Work Area

- 1.4.7 2. Versatility

- 1.4.8 3. Cost-Effectiveness

- 1.4.9 4. Safety and Convenience

- 1.5 Applications of Small Wood Laser Cutter Machines

- 1.5.10 1. Home and Hobby Projects

- 1.5.11 2. Small-Scale Production

- 1.5.12 3. Education and Research

- 1.6 Conclusion

- 1.7 FAQs

Key Features of Small Wood Laser Cutter Machines

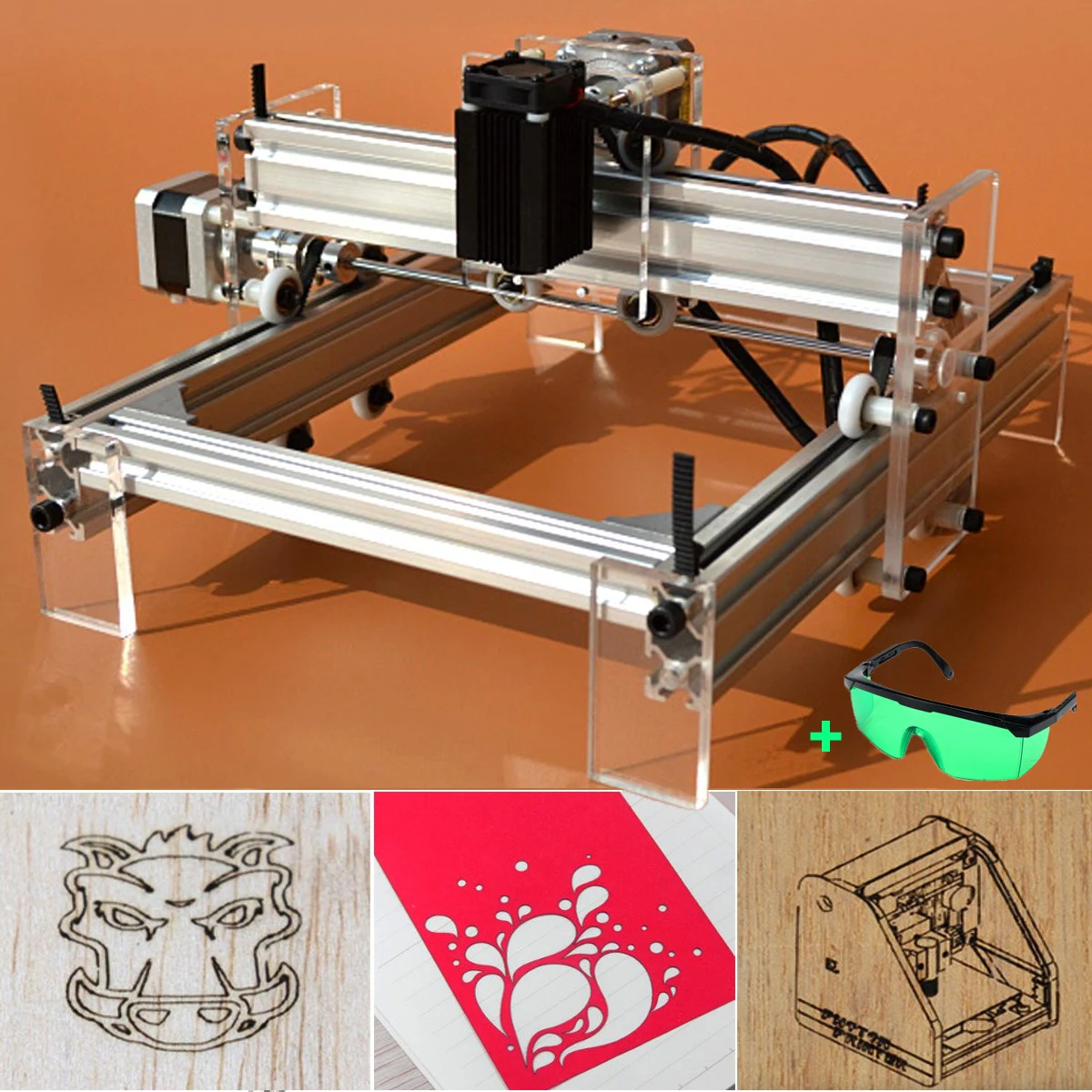

The laser power, measured in watts (W), determines the thickness and speed at which the laser can cut through wood. Small wood laser cutter machines typically have laser power ranging from 40W to 100W, suitable for cutting and engraving various wood types. The laser wavelength, typically 1064nm, is optimized for wood processing.

2. Work Area

The work area, measured in millimeters (mm), defines the maximum size of material that can be processed. Small wood laser cutter machines typically have work areas ranging from 300mm x 200mm to 600mm x 400mm, providing ample space for most projects.

3. Cutting and Engraving Speed

The cutting and engraving speed, measured in millimeters per second (mm/s), determines the efficiency of the machine. Faster speeds enable faster production, while slower speeds result in higher precision. Small wood laser cutter machines offer variable cutting and engraving speeds to accommodate different materials and project requirements.

4. Software and Connectivity

DOWNLOAD SVG FILES FOR LASER CUTTING

The software included with the machine allows users to design and control the cutting and engraving process. Compatibility with popular design software, such as CorelDRAW and AutoCAD, ensures seamless integration into existing workflows. Connectivity options, such as USB and Ethernet, enable easy file transfer and remote operation.

Benefits of Small Wood Laser Cutter Machines

1. Precision and Accuracy

Laser cutting technology provides unmatched precision and accuracy, resulting in clean, sharp cuts and intricate designs. This eliminates the need for manual cutting and sanding, saving time and reducing errors.

Small wood laser cutter machines have revolutionized the woodworking industry, enabling hobbyists and professionals alike to create intricate designs and precise cuts with ease. These compact machines offer a versatile and cost-effective solution for cutting, engraving, and marking a wide range of wood materials. This comprehensive guide will delve into the features, benefits, and applications of small wood laser cutter machines, providing valuable insights for potential users.

- Laser Engraver For Wood And Glass Laser Engraver For Wood And Glass: The Ultimate Guide To Precision Engraving

- Laser Cut Wooden Signs Near Me Laser Cut Wooden Signs Near Me: Elevate Your Décor With Precision And Style

- Wood Laser Cutting Machine Wood Laser Cutting Machine: Precision And Versatility For Woodworking

- Best Laser Wood Engraver Best Laser Wood Engraver: A Comprehensive Guide For Precision And Creativity

- Wood Laser Cutter Bunnings Wood Laser Cutter Bunnings: The Ultimate Guide To Choosing And Using

Key Features of Small Wood Laser Cutter Machines

1. Laser Power and Wavelength

DOWNLOAD SVG FILES FOR LASER CUTTING

The laser power, measured in watts (W), determines the thickness and speed at which the laser can cut through wood. Small wood laser cutter machines typically have laser power ranging from 40W to 100W, suitable for cutting and engraving various wood types. The laser wavelength, typically 1064nm, is optimized for wood processing.

2. Work Area

The work area, measured in millimeters (mm), defines the maximum size of material that can be processed. Small wood laser cutter machines typically have work areas ranging from 300mm x 200mm to 600mm x 400mm, providing ample space for most projects.

2. Versatility

Small wood laser cutter machines can process a wide range of wood materials, including hardwoods, softwoods, plywood, and MDF. They can perform a variety of tasks, including cutting, engraving, etching, and marking, making them ideal for diverse applications.

3. Cost-Effectiveness

Compared to traditional woodworking tools, small wood laser cutter machines offer a cost-effective solution. They reduce material waste, eliminate the need for expensive tooling, and increase productivity, resulting in significant savings over time.

4. Safety and Convenience

Laser cutting is a non-contact process, eliminating the risk of injuries associated with traditional cutting tools. The machines are designed with safety features, such as enclosed work areas and fume extraction systems, ensuring a safe and convenient user experience.

Applications of Small Wood Laser Cutter Machines

1. Home and Hobby Projects

Small wood laser cutter machines are perfect for hobbyists and DIY enthusiasts. They enable the creation of personalized gifts, home décor, and small-scale products with intricate designs and precise cuts.

2. Small-Scale Production

Entrepreneurs and small businesses can use small wood laser cutter machines for small-scale production of wood products, such as custom signs, engraved gifts, and personalized items. They offer a cost-effective and efficient way to produce high-quality products.

3. Education and Research

Educational institutions and research labs can utilize small wood laser cutter machines for prototyping, model making, and teaching purposes. They provide a safe and accessible way to explore laser cutting technology and its applications in various fields.

Conclusion

Small wood laser cutter machines are a valuable asset for both hobbyists and professionals. They offer precision, accuracy, versatility, cost-effectiveness, and safety, making them an ideal solution for a wide range of applications. When choosing a small wood laser cutter machine, consider the laser power, work area, cutting and engraving speed, software compatibility, and safety features to ensure it meets your specific requirements.

FAQs

Q: What materials can a small wood laser cutter machine cut?

A: Small wood laser cutter machines can cut a wide range of wood materials, including hardwoods, softwoods, plywood, and MDF.

Q: How thick can a small wood laser cutter machine cut?

A: The cutting thickness depends on the laser power of the machine. Typically, small wood laser cutter machines with 40W to 100W laser power can cut wood up to 10mm thick.

Q: Is it safe to use a small wood laser cutter machine?

A: Yes, small wood laser cutter machines are designed with safety features, such as enclosed work areas and fume extraction systems, ensuring a safe user experience. However, it is important to follow the manufacturer’s instructions and wear appropriate safety gear.

Q: What software do I need to use a small wood laser cutter machine?

A: Most small wood laser cutter machines come with proprietary software or are compatible with popular design software, such as CorelDRAW and AutoCAD.

Q: How do I maintain a small wood laser cutter machine?

A: Regular maintenance is crucial to ensure optimal performance and longevity. Clean the lens, mirrors, and work area regularly, and check the alignment of the laser beam. Follow the manufacturer’s recommended maintenance schedule for specific instructions.