Snapmaker CNC: Unleashing Precision and Versatility for Woodworking

Introduction

The Snapmaker CNC is a revolutionary machine that combines the power of 3D printing, laser engraving, and CNC milling into a single, compact device. With its versatile capabilities, the Snapmaker CNC excels in cutting wood with unmatched precision and efficiency.

Table of Content

- 1 Snapmaker CNC: Unleashing Precision and Versatility for Woodworking

- 1.1 Introduction

- 1.2 Understanding CNC Woodworking

- 1.3 Benefits of Using Snapmaker CNC for Woodworking

- 1.4 Step-by-Step Guide to Cutting Wood with Snapmaker CNC

- 1.5 Understanding CNC Woodworking

- 1.6 Benefits of Using Snapmaker CNC for Woodworking

- 1.7 Advanced Techniques for Woodworking with Snapmaker CNC

- 1.8 Conclusion

- 1.9 FAQs

Understanding CNC Woodworking

Benefits of Using Snapmaker CNC for Woodworking

1. Precision and Accuracy:

The Snapmaker CNC boasts a high-precision spindle and robust construction, ensuring exceptional accuracy in wood cutting. Its rigid frame and advanced motion control system minimize vibrations and deliver consistent results.

2. Versatility:

The Snapmaker CNC is not limited to wood cutting. It can also perform 3D printing and laser engraving, making it an all-in-one solution for various fabrication needs. This versatility saves time and space by eliminating the need for multiple machines.

3. Compact and User-Friendly:

Unlike traditional CNC machines, the Snapmaker CNC is compact and easy to use. Its intuitive software and user-friendly interface make it accessible to both hobbyists and professionals alike.

4. Wide Material Compatibility:

The Snapmaker CNC can cut a wide range of wood types, including hardwoods, softwoods, and engineered woods. Its powerful spindle and variable speed settings allow for precise cutting of different materials.

Step-by-Step Guide to Cutting Wood with Snapmaker CNC

The Snapmaker CNC is a revolutionary machine that combines the power of 3D printing, laser engraving, and CNC milling into a single, compact device. With its versatile capabilities, the Snapmaker CNC excels in cutting wood with unmatched precision and efficiency.

- Thingiverse Laser Cut Thingiverse Laser Cut: Unleashing The Power Of Digital Fabrication

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

- Laser Cutting Ender 3 Laser Cutting Ender 3: A Comprehensive Guide To Enhancing Your 3D Printer’s Capabilities

- 3d Laser Cut Wood 3D Laser Cut Wood: Unlocking Intricate Designs And Precision Craftsmanship

- 3d Tube Cutting 3D Tube Cutting: A Comprehensive Guide To Advanced Manufacturing

Understanding CNC Woodworking

CNC (Computer Numerical Control) machining involves using a computer-controlled machine to cut or shape materials. In the case of woodworking, a CNC machine utilizes a rotating cutting tool to remove material from the workpiece, resulting in intricate designs and accurate cuts.

Benefits of Using Snapmaker CNC for Woodworking

1. Precision and Accuracy:

The Snapmaker CNC boasts a high-precision spindle and robust construction, ensuring exceptional accuracy in wood cutting. Its rigid frame and advanced motion control system minimize vibrations and deliver consistent results.

1. Prepare the Wood:

2. Design the Cut:

- Create a design using CAD software or import existing designs.

- Convert the design into a G-code file, which contains instructions for the CNC machine.

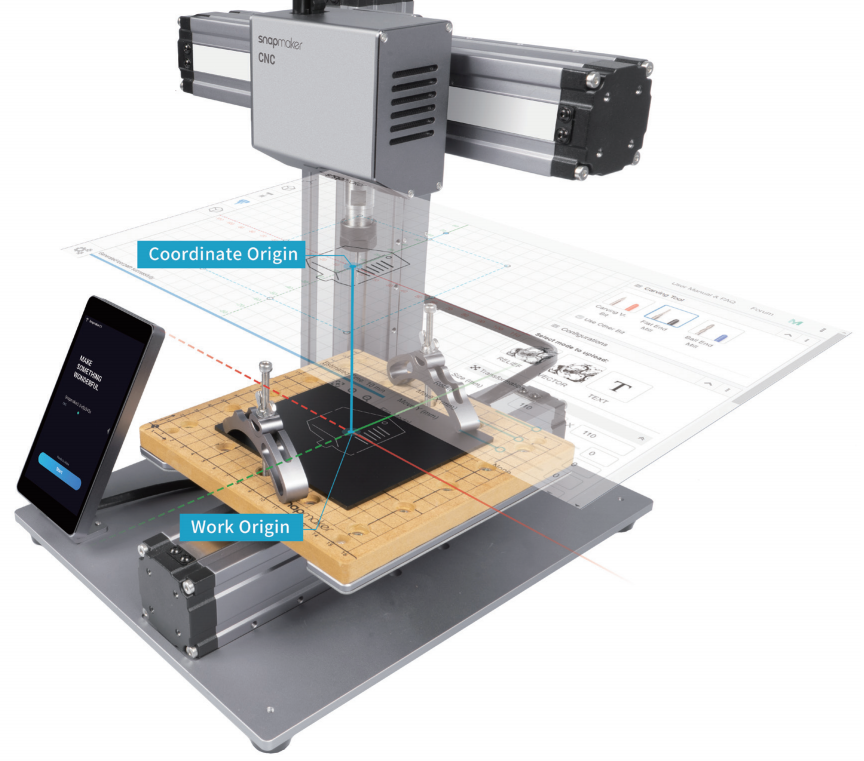

3. Set Up the Snapmaker CNC:

- Secure the wood onto the cutting bed using clamps or double-sided tape.

- Install the appropriate cutting tool (e.g., end mill, drill bit).

- Set the cutting parameters, such as speed, feed rate, and depth of cut.

4. Start the Cut:

- Load the G-code file into the Snapmaker software.

- Start the cutting process and monitor the progress.

Advanced Techniques for Woodworking with Snapmaker CNC

1. Inlay and Engraving:

The Snapmaker CNC can be used to create intricate inlays by cutting recesses into the wood and filling them with different materials. It can also engrave designs or text onto wood surfaces.

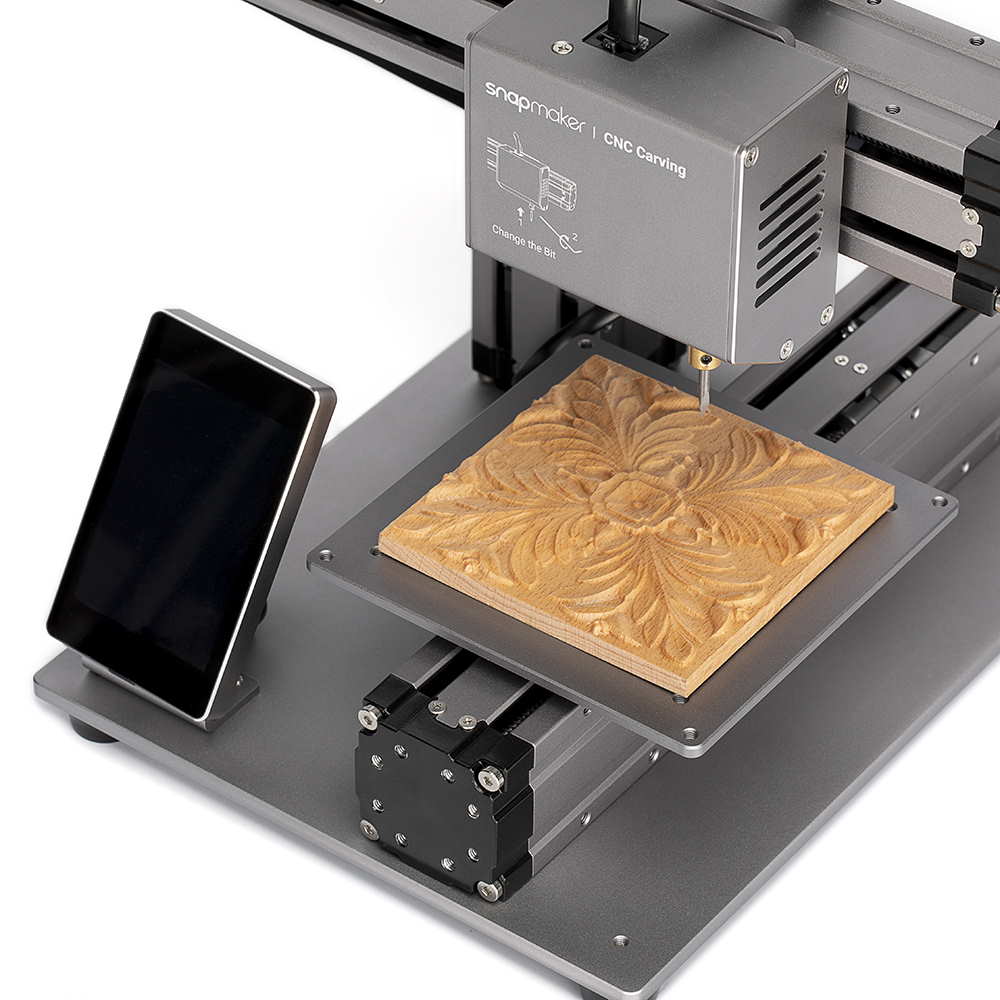

2. 3D Carving:

By combining 3D printing and CNC cutting, the Snapmaker CNC can produce complex 3D carvings from wood. This technique allows for the creation of unique and highly detailed objects.

3. Intarsia:

Intarsia is a woodworking technique that involves cutting and assembling pieces of different woods to create a larger design. The Snapmaker CNC’s precision and versatility make it ideal for this intricate art form.

Conclusion

The Snapmaker CNC is a game-changer for woodworking enthusiasts and professionals alike. Its precision, versatility, and ease of use make it an exceptional tool for cutting wood with unmatched accuracy and efficiency. Whether you’re a hobbyist looking to create custom projects or a professional seeking to expand your capabilities, the Snapmaker CNC is the ultimate solution.

FAQs

1. What types of wood can the Snapmaker CNC cut?

The Snapmaker CNC can cut a wide range of wood types, including hardwoods, softwoods, and engineered woods.

2. What is the maximum cutting depth of the Snapmaker CNC?

The maximum cutting depth depends on the cutting tool used. Generally, it ranges from 0.5mm to 10mm.

3. Can the Snapmaker CNC be used to cut metal?

No, the Snapmaker CNC is not designed for metal cutting. However, it can be used to engrave metal surfaces.

4. Is the Snapmaker CNC software easy to use?

Yes, the Snapmaker software is intuitive and user-friendly, making it accessible to both beginners and experienced users.

5. Where can I find support for using the Snapmaker CNC?

Snapmaker provides comprehensive support through its online documentation, community forums, and dedicated customer service team.