Wood Laser Cutter Australia: The Ultimate Guide to Laser Cutting Technology

Introduction

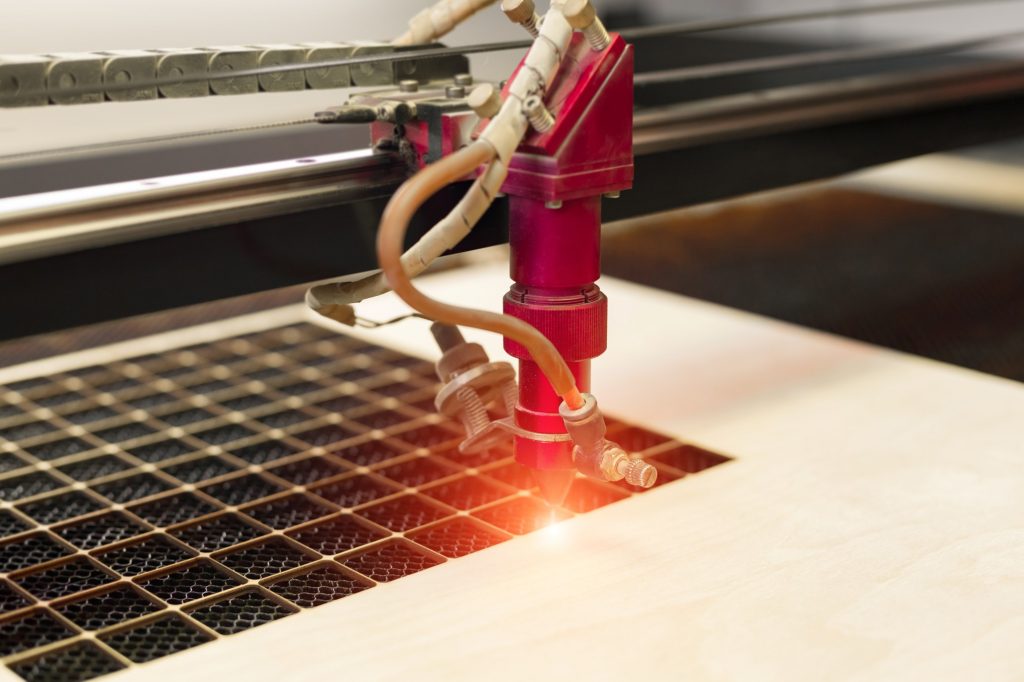

Laser cutting is a revolutionary technology that has transformed the woodworking industry. With the advent of wood laser cutters in Australia, businesses and hobbyists alike can now create intricate and precise cuts in wood with unprecedented speed and accuracy. This article will delve into the world of wood laser cutters, exploring their capabilities, benefits, and applications in the Australian market.

Table of Content

- 1 Wood Laser Cutter Australia: The Ultimate Guide to Laser Cutting Technology

- 1.1 Introduction

- 2 H1: Understanding Wood Laser Cutters

- 2.2 H3: Types of Wood Laser Cutters

- 2.3 H2: Benefits of Wood Laser Cutters

- 3 H1: Understanding Wood Laser Cutters

- 3.4 H2: How Laser Cutting Works

- 3.5 H3: Types of Wood Laser Cutters

- 4 H1: Applications of Wood Laser Cutters in Australia

- 4.6 H2: Industrial Applications

- 4.7 H3: Small Business and Home Use

- 5 H1: Choosing the Right Wood Laser Cutter for Your Needs

- 5.8 H2: Factors to Consider

- 6 H1: Conclusion

- 7 H1: FAQs

- 7.9 H2: What are the safety precautions for using a wood laser cutter?

- 7.10 H2: Can wood laser cutters cut metal?

- 7.11 H2: How do I maintain a wood laser cutter?

H1: Understanding Wood Laser Cutters

Laser cutting involves directing a high-powered laser beam onto the surface of wood, vaporizing the material and creating a clean, precise cut. The laser beam is typically generated by a carbon dioxide (CO2) laser or a fiber laser.

H3: Types of Wood Laser Cutters

There are two main types of wood laser cutters:

- CO2 Laser Cutters: CO2 lasers emit infrared light and are commonly used for cutting and engraving wood, acrylic, and other non-metallic materials.

- Fiber Laser Cutters: Fiber lasers emit visible light and are known for their high power density and cutting speed. They are suitable for cutting a wider range of materials, including metals.

H2: Benefits of Wood Laser Cutters

Laser cutting offers numerous advantages over traditional woodworking methods:

- Best Laser Wood Cutter Best Laser Wood Cutter: A Comprehensive Guide

- Laser Cut Wooden Rabbit Laser Cut Wooden Rabbit: A Unique And Charming Creation

- Wooden Laser Cutting Design Wooden Laser Cutting Design: A Comprehensive Guide

- Laser Cut Wooden Bow Tie Laser Cut Wooden Bow Tie: A Stylish And Sustainable Accessory

- Laser Cut Wooden Stars Laser Cut Wooden Stars: A Guide To Crafting Stunning Ornaments And Decorations

- Precision: Lasers produce incredibly precise cuts with minimal burrs or rough edges.

- Speed: Laser cutters can cut wood at high speeds, significantly reducing production time.

- Versatility: Laser cutters can cut a wide variety of wood species and thicknesses.

- Intricate Designs: Lasers can create complex and intricate designs with ease, enabling the production of unique and personalized products.

- Reduced Waste: Laser cutting minimizes material waste by utilizing a non-contact process.

Laser cutting is a revolutionary technology that has transformed the woodworking industry. With the advent of wood laser cutters in Australia, businesses and hobbyists alike can now create intricate and precise cuts in wood with unprecedented speed and accuracy. This article will delve into the world of wood laser cutters, exploring their capabilities, benefits, and applications in the Australian market.

H1: Understanding Wood Laser Cutters

H2: How Laser Cutting Works

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting involves directing a high-powered laser beam onto the surface of wood, vaporizing the material and creating a clean, precise cut. The laser beam is typically generated by a carbon dioxide (CO2) laser or a fiber laser.

H3: Types of Wood Laser Cutters

There are two main types of wood laser cutters:

H1: Applications of Wood Laser Cutters in Australia

H2: Industrial Applications

Wood laser cutters are widely used in industrial settings for various applications, including:

- Furniture Manufacturing: Cutting intricate designs for furniture components, such as tabletops, chair legs, and headboards.

- Architectural Elements: Producing decorative trims, moldings, and other architectural features.

- Toys and Games: Creating wooden toys, game pieces, and puzzles with precise shapes and details.

H3: Small Business and Home Use

Laser cutters are also gaining popularity among small businesses and hobbyists in Australia:

- Craft and DIY Projects: Creating custom signs, home décor, and other decorative items.

- Jewelry Making: Cutting intricate designs in wood for jewelry making.

- Model Building: Producing detailed model parts for hobbies such as model trains and airplanes.

H1: Choosing the Right Wood Laser Cutter for Your Needs

H2: Factors to Consider

When selecting a wood laser cutter, consider the following factors:

- Power: The laser power determines the thickness and speed at which you can cut wood.

- Cutting Area: The cutting area defines the maximum size of wood you can cut.

- Material Compatibility: Ensure the laser cutter can handle the types of wood you intend to cut.

- Software Compatibility: Choose a laser cutter that is compatible with your design software.

- Safety Features: Look for laser cutters with safety features such as enclosed work areas and fume extraction systems.

H1: Conclusion

Wood laser cutters have revolutionized the woodworking industry in Australia, providing businesses and individuals with a powerful tool for creating precise, intricate, and versatile products. From industrial applications to small business and home use, laser cutting offers numerous benefits over traditional methods. By carefully considering your needs and selecting the right laser cutter, you can unlock the full potential of this transformative technology.

H1: FAQs

H2: What are the safety precautions for using a wood laser cutter?

- Always wear appropriate safety gear, including laser safety glasses and gloves.

- Operate the laser cutter in a well-ventilated area.

- Keep flammable materials away from the cutting area.

H2: Can wood laser cutters cut metal?

- Fiber laser cutters can cut thin sheets of metal, but they are not as effective as dedicated metal laser cutters.

H2: How do I maintain a wood laser cutter?

- Regularly clean the laser lens and mirrors.

- Calibrate the laser cutter periodically to ensure optimal performance.

- Check the fume extraction system to ensure proper airflow.