Wood Laser Cutter Cost: A Comprehensive Guide

Introduction

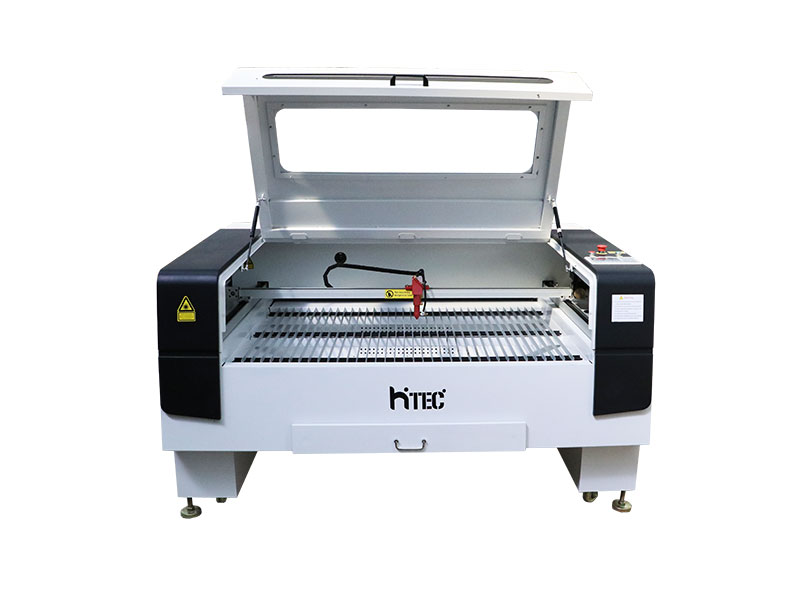

Laser cutters are revolutionizing the woodworking industry, enabling precise cutting, intricate designs, and rapid production. Understanding the cost of a wood laser cutter is crucial for businesses and individuals considering this technology. This article provides a comprehensive guide to wood laser cutter costs, covering factors that influence pricing and offering insights into the return on investment.

Table of Content

Factors Influencing Wood Laser Cutter Cost

The laser power determines the cutting speed, depth, and material compatibility. Higher-powered lasers cut faster and deeper, enabling thicker materials to be processed. Expect higher costs for lasers with increased wattage.

2. Laser Type:

Different laser types, such as CO2, fiber, and diode, have varying capabilities and price points. CO2 lasers are widely used for wood cutting, while fiber lasers offer higher precision and durability at a premium cost.

3. Bed Size:

The working area of the laser cutter determines the size of the materials that can be processed. Larger bed sizes allow for cutting larger projects, but come at a higher cost.

4. Automation: DOWNLOAD SVG FILES FOR LASER CUTTING

Automated features, such as auto-focus, nesting, and material handling, enhance efficiency and accuracy. These features increase the overall cost of the laser cutter.

5. Software:

Laser cutting software controls the machine’s operation, design creation, and material optimization. Advanced software with comprehensive features commands a higher price.

6. Brand Reputation:

Laser cutters are revolutionizing the woodworking industry, enabling precise cutting, intricate designs, and rapid production. Understanding the cost of a wood laser cutter is crucial for businesses and individuals considering this technology. This article provides a comprehensive guide to wood laser cutter costs, covering factors that influence pricing and offering insights into the return on investment.

- Laser Drawing On Wood Laser Drawing On Wood: A Comprehensive Guide To Pyrography And Laser Engraving

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Wood Laser Cutter Australia Wood Laser Cutter Australia: The Ultimate Guide To Laser Cutting Technology

- Laser Cutouts Wood Laser Cutouts Wood: A Comprehensive Guide To Precision Cutting And Customization

- Wooden Laser Cut Easter Basket H1: Elevate Your Easter Celebrations With A Wooden Laser Cut Easter Basket: A Timeless Keepsake

Factors Influencing Wood Laser Cutter Cost

1. Laser Power: DOWNLOAD SVG FILES FOR LASER CUTTING

The laser power determines the cutting speed, depth, and material compatibility. Higher-powered lasers cut faster and deeper, enabling thicker materials to be processed. Expect higher costs for lasers with increased wattage.

2. Laser Type:

Different laser types, such as CO2, fiber, and diode, have varying capabilities and price points. CO2 lasers are widely used for wood cutting, while fiber lasers offer higher precision and durability at a premium cost.

Established brands with a track record of reliability and support typically charge a premium for their laser cutters.

Cost Breakdown

The average cost of a wood laser cutter can range from $10,000 to $100,000 depending on the aforementioned factors.

Entry-Level (Under $20,000):

Suitable for hobbyists and small businesses. Offers basic features, limited power, and a small bed size.

Mid-Range ($20,000 – $50,000):

Ideal for small to medium-sized businesses. Provides enhanced power, bed size, and automation features.

High-End ($50,000 – $100,000):

Designed for large-scale production and demanding applications. Features high laser power, large bed size, and advanced automation capabilities.

Return on Investment (ROI)

The ROI of a wood laser cutter depends on factors such as:

1. Production Volume:

Higher production volumes lead to increased revenue and faster ROI.

2. Material Costs:

Laser cutting can significantly reduce material waste compared to traditional cutting methods, resulting in cost savings.

3. Labor Costs:

Automated laser cutters reduce labor requirements, freeing up resources for other tasks.

4. Product Value:

Laser-cut products offer increased precision, intricate designs, and higher perceived value, potentially commanding premium prices.

Conclusion

Understanding the cost of a wood laser cutter is essential for making an informed decision. By considering the factors that influence pricing and calculating the potential ROI, businesses and individuals can determine if a laser cutter is a viable investment for their specific needs.

FAQs

1. Is it cheaper to buy or lease a wood laser cutter?

Leasing can offer lower upfront costs, but buying provides long-term ownership and potential resale value.

2. What are the ongoing costs of owning a wood laser cutter?

Maintenance, consumables (e.g., lenses, nozzles), and electricity consumption are ongoing costs.

3. How can I reduce the cost of laser cutting?

Optimize material usage, use nesting software, and maintain the laser cutter regularly.

4. What is the lifespan of a wood laser cutter?

With proper maintenance, a wood laser cutter can last 5-10 years or more.

5. Where can I find a reputable supplier of wood laser cutters?

Research online marketplaces, attend industry events, and consult with experienced laser cutter users.