Wood Laser Cutter Images: Unlocking Precision and Creativity

Introduction

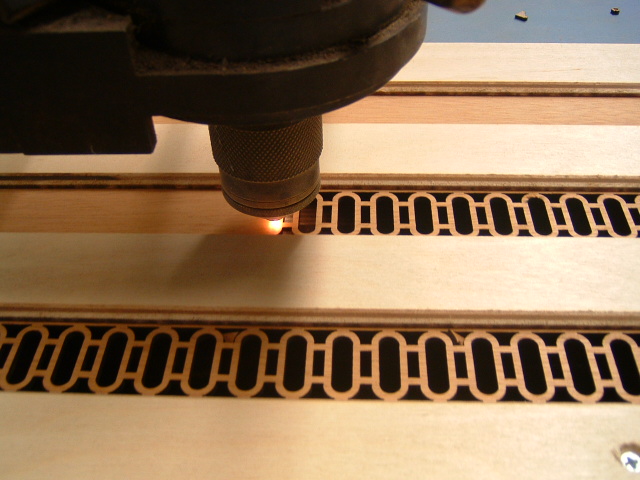

Laser cutting technology has revolutionized the woodworking industry, empowering makers and businesses to create intricate and precise designs with unprecedented accuracy. Wood laser cutter images have become an essential tool for producing high-quality wood products, from custom furniture and home décor to architectural elements and industrial applications.

Table of Content

- 1 Wood Laser Cutter Images: Unlocking Precision and Creativity

- 1.1 Introduction

- 1.2 Advantages of Laser Cutting Wood

- 1.3 Choosing the Right Wood Laser Cutter

- 1.4 Types of Wood Laser Cutter Images

- 1.5 Advantages of Laser Cutting Wood

- 1.6 Design Considerations for Wood Laser Cutter Images

- 1.7 Safety Precautions

- 1.8 Conclusion

- 2 FAQs

Advantages of Laser Cutting Wood

2. Intricate Designs: Laser cutting allows for the creation of complex and intricate designs that would be difficult or impossible to achieve with traditional woodworking methods.

3. High Speed and Efficiency: Laser cutters operate at high speeds, significantly reducing production time and increasing efficiency.

4. Reduced Material Waste: Laser cutting minimizes material waste by precisely cutting only the desired shapes, reducing material consumption and costs.

Choosing the Right Wood Laser Cutter

When selecting a wood laser cutter, consider the following factors:

1. Laser Power: The laser power determines the thickness and types of wood that can be cut. Higher power lasers are capable of cutting through thicker materials.

DOWNLOAD SVG FILES FOR LASER CUTTING

2. Bed Size: The bed size determines the maximum size of wood that can be cut. Choose a bed size that accommodates your project requirements.

3. Cutting Speed: The cutting speed affects production time. Opt for a laser cutter with a high cutting speed to maximize efficiency.

4. Software Compatibility: Ensure that the laser cutter is compatible with your preferred design software to facilitate seamless workflow.

Types of Wood Laser Cutter Images

Laser cutting technology has revolutionized the woodworking industry, empowering makers and businesses to create intricate and precise designs with unprecedented accuracy. Wood laser cutter images have become an essential tool for producing high-quality wood products, from custom furniture and home décor to architectural elements and industrial applications.

- Laser Cut Wooden Combs H1: Laser Cut Wooden Combs: A Guide To Crafting Unique And Eco-Friendly Hair Accessories

- Laser Cut Wood Images Laser Cut Wood Images: A Comprehensive Guide

- Laser Cut Wooden Signs Australia Laser Cut Wooden Signs Australia: The Ultimate Guide To Custom Engraved Decor

- Laser Cut Wooden Plaques Laser Cut Wooden Plaques: A Timeless Art Form For Recognition And Decor

- Wood Laser Cutter Cost Wood Laser Cutter Cost: A Comprehensive Guide

Advantages of Laser Cutting Wood

1. Precision and Accuracy: Laser cutters utilize focused laser beams to cut through wood with pinpoint accuracy, eliminating human error and ensuring consistent results.

DOWNLOAD SVG FILES FOR LASER CUTTING

2. Intricate Designs: Laser cutting allows for the creation of complex and intricate designs that would be difficult or impossible to achieve with traditional woodworking methods.

3. High Speed and Efficiency: Laser cutters operate at high speeds, significantly reducing production time and increasing efficiency.

4. Reduced Material Waste: Laser cutting minimizes material waste by precisely cutting only the desired shapes, reducing material consumption and costs.

1. Vector Images: Vector images are composed of lines and curves defined by mathematical equations. They are ideal for cutting precise shapes and patterns.

2. Raster Images: Raster images are made up of pixels and are suitable for creating images with gradients and textures.

Design Considerations for Wood Laser Cutter Images

1. Image Resolution: High-resolution images produce sharp and detailed cuts. Use images with a resolution of at least 300 dpi.

2. Image Format: Vector images are preferred for laser cutting due to their precise nature. Convert raster images to vector format for optimal results.

3. Kerf Width: The kerf width is the width of the material removed by the laser. Consider the kerf width when designing your images to ensure proper fit and alignment.

Safety Precautions

1. Eye Protection: Always wear appropriate eye protection when operating a laser cutter to prevent eye damage from the laser beam.

2. Ventilation: Ensure adequate ventilation to remove fumes and particles generated during laser cutting.

3. Fire Safety: Keep a fire extinguisher nearby and take precautions to prevent fires.

Conclusion

Wood laser cutter images have revolutionized the woodworking industry, providing makers and businesses with the ability to create intricate and precise designs with ease. By understanding the advantages, choosing the right laser cutter, and following design considerations, you can unlock the full potential of laser cutting technology and produce stunning wood products.

FAQs

Q: What types of wood can be laser cut?

A: Most types of wood can be laser cut, including hardwoods, softwoods, and engineered wood.

Q: Can laser cutters engrave wood?

A: Yes, laser cutters can engrave wood by rastering a design onto the surface.

Q: How thick can wood be laser cut?

A: The maximum thickness of wood that can be laser cut depends on the laser power and the type of wood. Typically, lasers with higher power can cut thicker materials.

Q: Is laser cutting wood dangerous?

A: Laser cutting wood can be dangerous if proper safety precautions are not followed. Always wear eye protection, ensure adequate ventilation, and take fire safety measures.

Q: What software is used for laser cutting wood?

A: Laser cutters are compatible with a variety of design software, such as AutoCAD, CorelDRAW, and Adobe Illustrator.