Wood Laser Cutter Router: Revolutionizing Woodworking with Precision and Efficiency

Introduction

Wood laser cutter routers are innovative tools that combine the precision of laser cutting with the versatility of a CNC router, enabling woodworkers to create intricate and precise designs with unparalleled efficiency. This comprehensive guide will delve into the world of wood laser cutter routers, exploring their capabilities, benefits, and considerations for choosing the right model.

Table of Content

- 1 Wood Laser Cutter Router: Revolutionizing Woodworking with Precision and Efficiency

- 1.1 Introduction

- 1.2 Understanding Wood Laser Cutter Routers

- 1.2.1 H2.2: Types of Wood Laser Cutter Routers

- 1.3 Benefits of Wood Laser Cutter Routers

- 1.3.2 H3.1: Precision and Accuracy

- 1.4 Understanding Wood Laser Cutter Routers

- 1.4.3 H2.1: Laser Cutting vs. CNC Routing

- 1.4.4 H2.2: Types of Wood Laser Cutter Routers

- 1.4.5 H3.2: Versatility and Flexibility

- 1.4.6 H3.3: Speed and Efficiency

- 1.4.7 H3.4: Reduced Material Waste

- 1.5 Considerations for Choosing a Wood Laser Cutter Router

- 1.5.8 H4.1: Laser Power

- 1.5.9 H4.2: Bed Size

- 1.5.10 H4.3: Software Compatibility

- 1.5.11 H4.4: Safety Features

- 1.6 Conclusion

- 1.7 FAQs

- 1.7.12 Q1: What materials can a wood laser cutter router cut?

- 1.7.13 Q2: What is the difference between a CO2 and a fiber laser cutter?

- 1.7.14 Q3: How do I ensure safety when using a wood laser cutter router?

- 1.7.15 Q4: What software is used to control a wood laser cutter router?

Understanding Wood Laser Cutter Routers

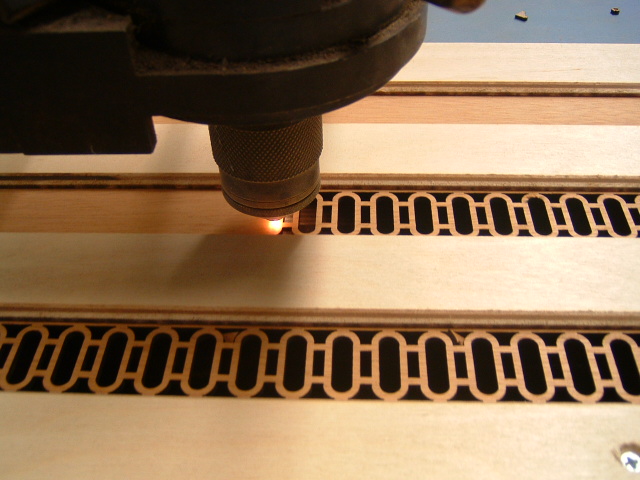

Laser cutting involves using a high-powered laser to vaporize or burn away material, creating precise cuts. CNC routing, on the other hand, uses a rotating cutting tool to remove material, providing versatility for shaping and carving. Wood laser cutter routers combine these technologies, allowing for both precise laser cutting and intricate routing operations.

H2.2: Types of Wood Laser Cutter Routers

Wood laser cutter routers come in two primary types:

- CO2 Laser Cutters: These lasers emit carbon dioxide and are suitable for cutting a wide range of materials, including wood, acrylic, and leather.

- Fiber Laser Cutters: These lasers use a fiber optic cable to deliver the laser energy, resulting in higher precision and faster cutting speeds compared to CO2 lasers.

Benefits of Wood Laser Cutter Routers

H3.1: Precision and Accuracy

Laser cutting offers exceptional precision, allowing for intricate designs and precise cuts with minimal material waste. The laser beam’s narrow focus and controlled power output result in clean, burr-free edges.

Wood laser cutter routers are innovative tools that combine the precision of laser cutting with the versatility of a CNC router, enabling woodworkers to create intricate and precise designs with unparalleled efficiency. This comprehensive guide will delve into the world of wood laser cutter routers, exploring their capabilities, benefits, and considerations for choosing the right model.

- Laser Cut Wooden Calendar Laser Cut Wooden Calendar: A Timeless And Customizable Timepiece

- Laser Cut Wooden Hammer Laser Cut Wooden Hammer: The Ultimate Guide To Precision And Craftsmanship

- Wooden Laser Cut Boxes H1: Wooden Laser Cut Boxes: A Comprehensive Guide To Elegance And Functionality

- Laser Cut Wooden Business Cards Laser Cut Wooden Business Cards: A Unique And Eco-Friendly Way To Make A Statement

- Etching Wood Laser Cutter Etching Wood Laser Cutter: A Comprehensive Guide To Precision Woodworking

Understanding Wood Laser Cutter Routers

H2.1: Laser Cutting vs. CNC Routing

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting involves using a high-powered laser to vaporize or burn away material, creating precise cuts. CNC routing, on the other hand, uses a rotating cutting tool to remove material, providing versatility for shaping and carving. Wood laser cutter routers combine these technologies, allowing for both precise laser cutting and intricate routing operations.

H2.2: Types of Wood Laser Cutter Routers

Wood laser cutter routers come in two primary types:

H3.2: Versatility and Flexibility

Wood laser cutter routers provide versatility by combining laser cutting with CNC routing capabilities. They can create a wide range of designs, from intricate inlays to complex carvings, with ease.

H3.3: Speed and Efficiency

Laser cutting is a fast and efficient process, reducing production time and increasing output. CNC routing further enhances efficiency by automating the cutting process, eliminating the need for manual labor.

H3.4: Reduced Material Waste

Laser cutting minimizes material waste by vaporizing or burning away only the necessary material, resulting in cost savings and reduced environmental impact.

Considerations for Choosing a Wood Laser Cutter Router

H4.1: Laser Power

Laser power is a crucial factor that determines the thickness and materials that the laser can cut. Higher laser power allows for cutting thicker materials and achieving faster cutting speeds.

H4.2: Bed Size

The bed size of the laser cutter router determines the maximum size of the materials that can be processed. Consider the size of the projects you intend to create when selecting the appropriate bed size.

H4.3: Software Compatibility

The software used to control the laser cutter router is essential for designing and operating the machine. Ensure compatibility with the design software you use and the ability to import various file formats.

H4.4: Safety Features

Laser cutting involves the use of high-power lasers, so it’s crucial to prioritize safety. Look for machines with safety features such as enclosed workspaces, fume extraction systems, and emergency stop buttons.

Conclusion

Wood laser cutter routers are indispensable tools for woodworkers seeking precision, versatility, and efficiency. By combining the strengths of laser cutting and CNC routing, these machines empower craftsmen to create intricate and unique designs with ease. When selecting a wood laser cutter router, consider the laser power, bed size, software compatibility, and safety features to find the optimal model for your needs.

FAQs

Q1: What materials can a wood laser cutter router cut?

A1: Wood laser cutter routers can cut a wide range of materials, including wood, acrylic, leather, fabric, and thin metals.

Q2: What is the difference between a CO2 and a fiber laser cutter?

A2: CO2 lasers are suitable for cutting a wide range of materials, while fiber lasers offer higher precision and faster cutting speeds.

Q3: How do I ensure safety when using a wood laser cutter router?

A3: Always wear appropriate safety gear, operate the machine in a well-ventilated area, and follow the manufacturer’s safety guidelines.

Q4: What software is used to control a wood laser cutter router?

A4: Wood laser cutter routers use specialized software that allows for designing, importing files, and controlling the machine’s operations.