Wood Laser Cutter: The Ultimate Guide for Beginners and Professionals

Introduction

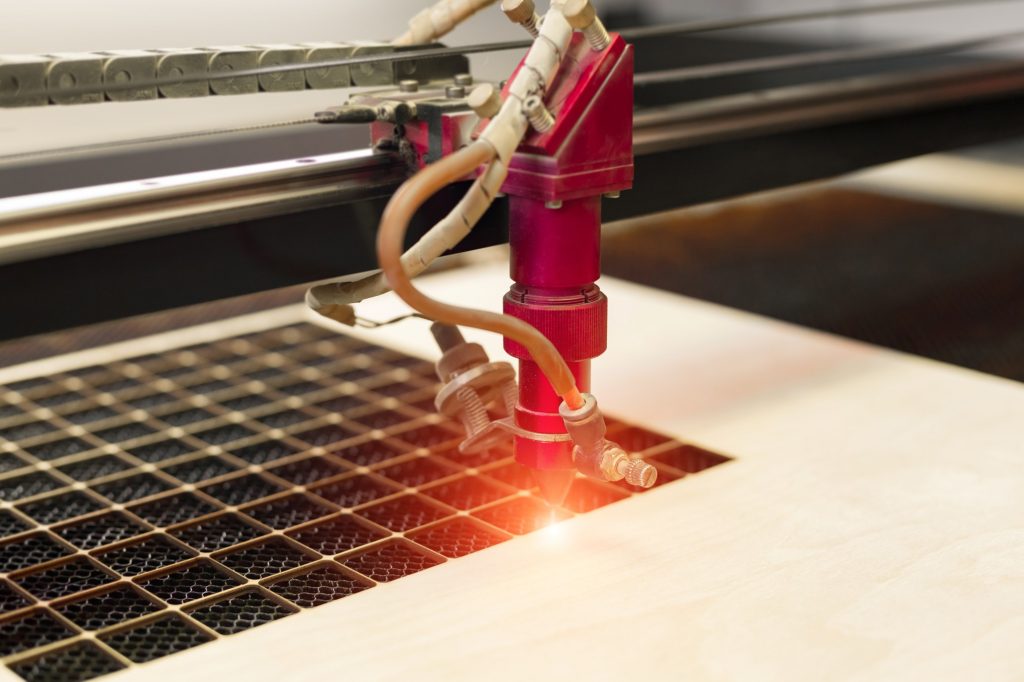

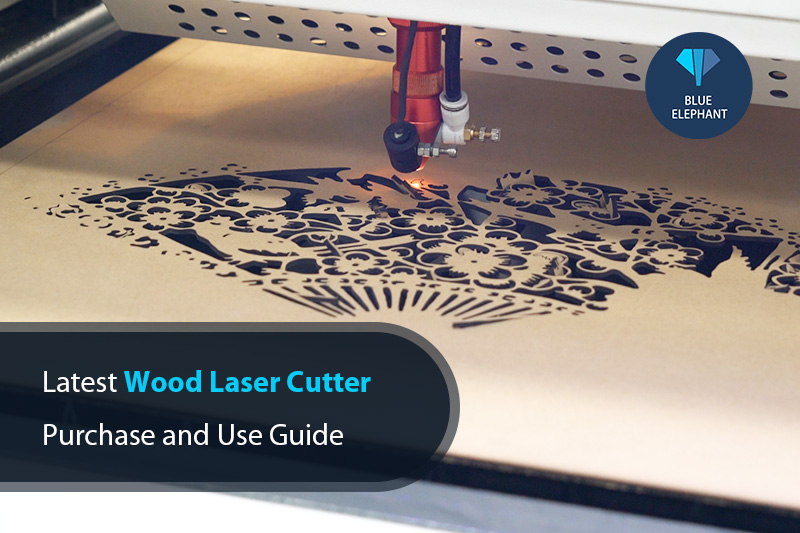

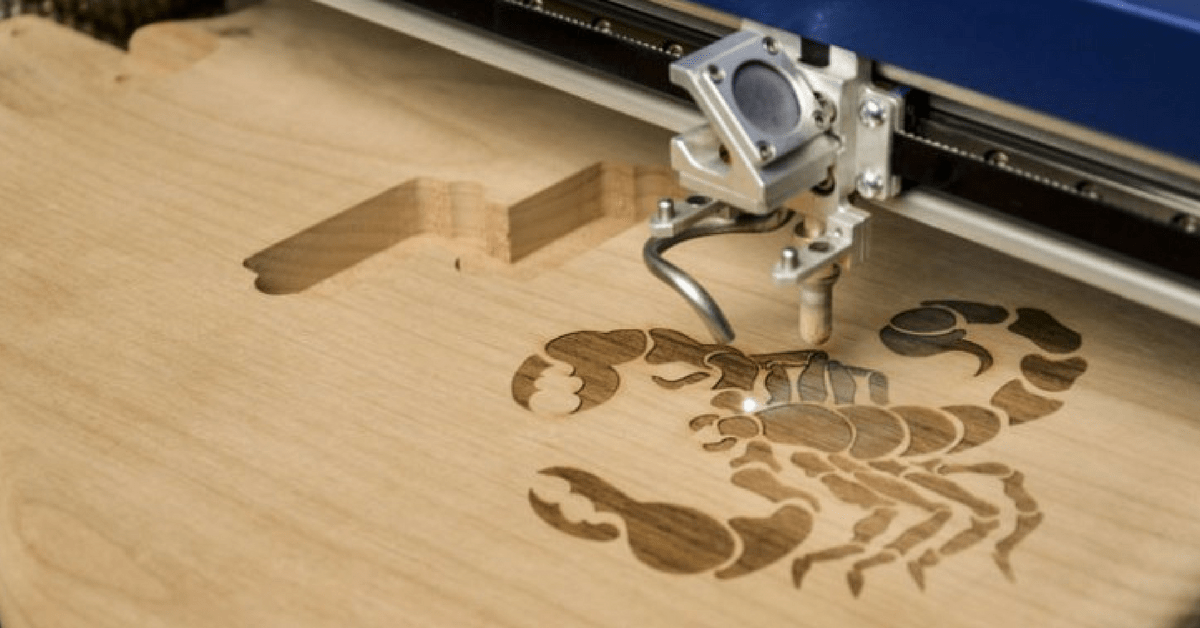

Wood laser cutters are revolutionary tools that have transformed the woodworking industry. These machines use high-powered lasers to cut, engrave, and etch intricate designs into wood, offering unparalleled precision and versatility. In this comprehensive guide, we will explore everything you need to know about wood laser cutters, from their types and features to their applications and benefits.

Table of Content

- 1 Wood Laser Cutter: The Ultimate Guide for Beginners and Professionals

- 1.1 Introduction

- 1.2 Types of Wood Laser Cutters

- 1.2.1 Fiber Laser Cutters

- 1.2.2 Diode Laser Cutters

- 1.3 Features to Consider

- 1.4 Types of Wood Laser Cutters

- 1.4.3 CO2 Laser Cutters

- 1.4.4 Fiber Laser Cutters

- 1.5 Applications of Wood Laser Cutters

- 1.6 Benefits of Wood Laser Cutters

- 1.7 How to Use a Wood Laser Cutter

- 1.8 Safety Precautions

- 1.9 Conclusion

- 1.10 FAQs

Types of Wood Laser Cutters

CO2 laser cutters are the most common type used for woodcutting. They emit a continuous beam of laser energy, which is absorbed by the wood and converted into heat. This heat vaporizes the wood, creating a clean and precise cut. CO2 lasers are known for their high power and cutting speed, making them suitable for large-scale production.

Fiber Laser Cutters

Fiber laser cutters are a newer technology that uses a solid-state fiber laser to generate the laser beam. They offer several advantages over CO2 lasers, including higher precision, faster cutting speeds, and lower maintenance costs. However, fiber laser cutters are more expensive and may not be suitable for all applications.

Diode Laser Cutters

Diode laser cutters use semiconductor diodes to produce the laser beam. They are the most affordable and compact type of wood laser cutter, making them ideal for hobbyists and small workshops. However, diode laser cutters have lower power and slower cutting speeds compared to CO2 and fiber lasers.

Features to Consider

DOWNLOAD SVG FILES FOR LASER CUTTING

When choosing a wood laser cutter, consider the following features:

- Laser Power: Measured in watts, laser power determines the thickness of wood that can be cut.

- Cutting Speed: The rate at which the laser cuts through the wood, affecting production efficiency.

- Custom Laser Cut Wood Panels Custom Laser Cut Wood Panels: Elevate Your Designs With Precision And Versatility

- Laser Cutting Mdf Laser Cutting MDF: A Comprehensive Guide

- Wooden Laser Printing Wooden Laser Printing: The Ultimate Guide To Precision Engraving On Wood

- Wood Laser Engraver And Cutter Wood Laser Engraver And Cutter: A Comprehensive Guide

- Large Wood Laser Cutter Large Wood Laser Cutter: The Ultimate Guide For Woodworking Professionals

- Cutting Area: The maximum size of the material that can be cut by the laser.

- Laser Source: The type of laser used (CO2, fiber, or diode) affects power, precision, and cost.

- Software Compatibility: Ensure that the laser cutter is compatible with your design software.

- Safety Features: Look for laser cutters with safety features such as enclosed workspaces and fume extraction systems.

Wood laser cutters are revolutionary tools that have transformed the woodworking industry. These machines use high-powered lasers to cut, engrave, and etch intricate designs into wood, offering unparalleled precision and versatility. In this comprehensive guide, we will explore everything you need to know about wood laser cutters, from their types and features to their applications and benefits.

Types of Wood Laser Cutters

CO2 Laser Cutters

DOWNLOAD SVG FILES FOR LASER CUTTING

CO2 laser cutters are the most common type used for woodcutting. They emit a continuous beam of laser energy, which is absorbed by the wood and converted into heat. This heat vaporizes the wood, creating a clean and precise cut. CO2 lasers are known for their high power and cutting speed, making them suitable for large-scale production.

Fiber Laser Cutters

Fiber laser cutters are a newer technology that uses a solid-state fiber laser to generate the laser beam. They offer several advantages over CO2 lasers, including higher precision, faster cutting speeds, and lower maintenance costs. However, fiber laser cutters are more expensive and may not be suitable for all applications.

Applications of Wood Laser Cutters

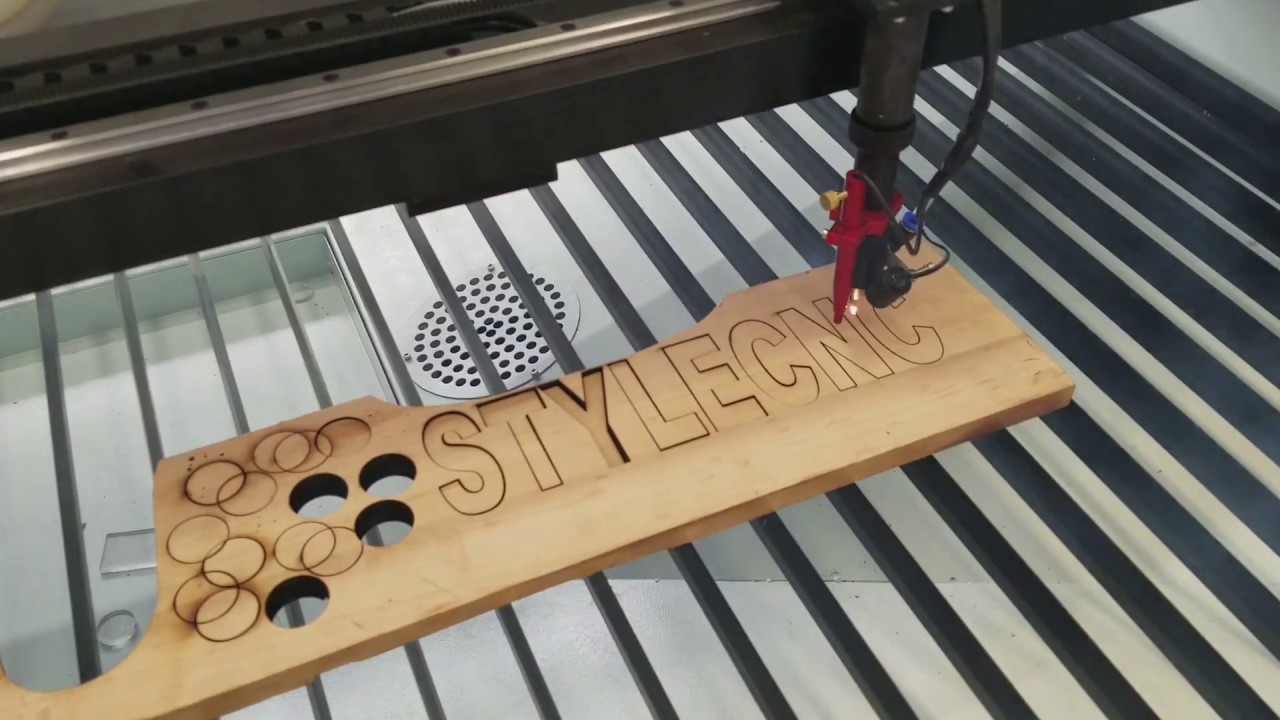

Wood laser cutters have a wide range of applications, including:

- Furniture Making: Cutting and engraving intricate designs into furniture pieces.

- Sign Making: Creating custom signs, logos, and lettering.

- Model Making: Building detailed architectural models and prototypes.

- Decorative Items: Producing unique home décor, such as coasters, wall art, and picture frames.

- Industrial Applications: Cutting and engraving wood components for industries such as automotive and construction.

Benefits of Wood Laser Cutters

- Precision Cutting: Laser cutters offer unmatched precision, producing clean and accurate cuts.

- Versatility: They can cut, engrave, and etch various wood species and thicknesses.

- Automation: Laser cutters can be programmed to perform repetitive tasks, increasing efficiency.

- Design Flexibility: Digital design software allows for the creation of complex and intricate designs.

- Reduced Waste: Laser cutters minimize material waste by optimizing cutting patterns.

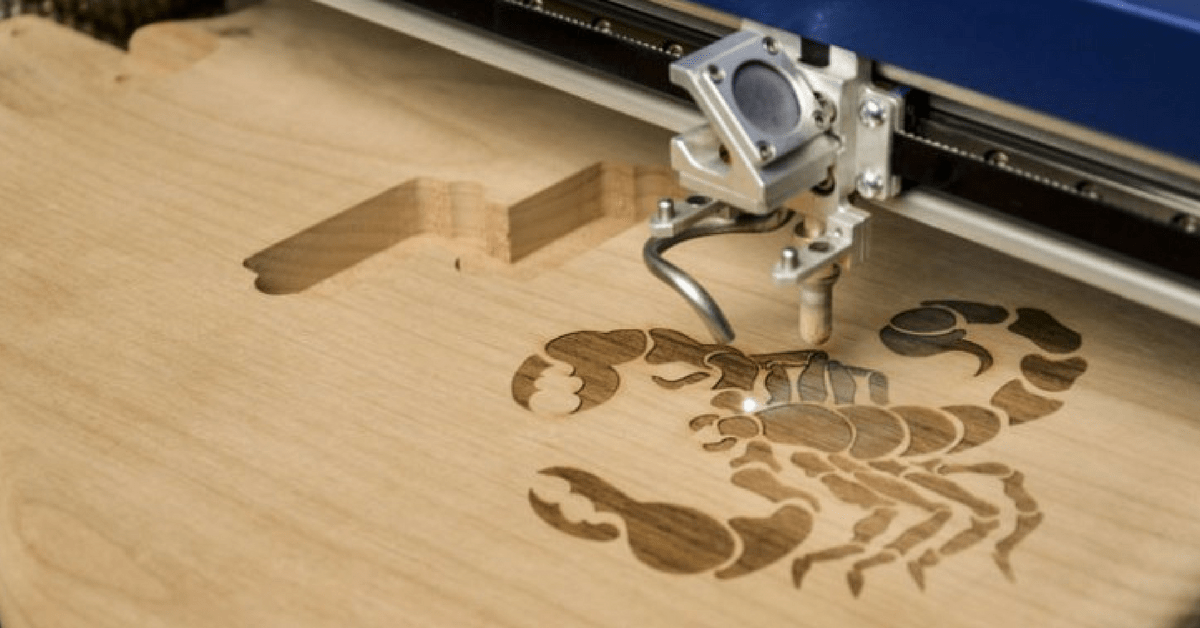

How to Use a Wood Laser Cutter

- Prepare the Wood: Choose the appropriate wood species and thickness for your project.

- Design the File: Create a digital design file in a compatible software program.

- Load the File: Transfer the design file to the laser cutter software.

- Set Up the Laser: Adjust the laser power, speed, and focus according to the wood type and desired cut quality.

- Start the Cutting Process: Place the wood in the laser cutter and initiate the cutting process.

- Post-Processing: Remove the cut or engraved wood and clean up any excess material.

Safety Precautions

- Wear Protective Gear: Use safety glasses, gloves, and a respirator to protect yourself from laser emissions and fumes.

- Enclosed Workspace: Operate the laser cutter in an enclosed workspace with proper ventilation.

- Fire Safety: Have a fire extinguisher nearby and be aware of potential fire hazards.

- Electrical Safety: Ensure proper electrical connections and grounding.

Conclusion

Wood laser cutters are indispensable tools for woodworking professionals and hobbyists alike. They offer precision, versatility, automation, and design flexibility. By understanding the different types, features, and applications of wood laser cutters, you can make an informed decision when selecting a machine that meets your specific needs. With proper safety precautions, you can safely and effectively use a wood laser cutter to create stunning and intricate designs in wood.

FAQs

-

What is the difference between a CO2 laser cutter and a fiber laser cutter?

- CO2 laser cutters use a gas-filled tube to generate the laser beam, while fiber laser cutters use a solid-state fiber laser. Fiber laser cutters offer higher precision and faster cutting speeds.

-

What is the maximum thickness of wood that a wood laser cutter can cut?

- The maximum thickness depends on the laser power and the type of wood. Generally, CO2 laser cutters can cut up to 1 inch of wood, while fiber laser cutters can cut up to 0.5 inches.

-

Is it safe to use a wood laser cutter?

- Yes, it is safe to use a wood laser cutter with proper safety precautions. Wear protective gear, operate the cutter in an enclosed workspace, and follow electrical safety guidelines.