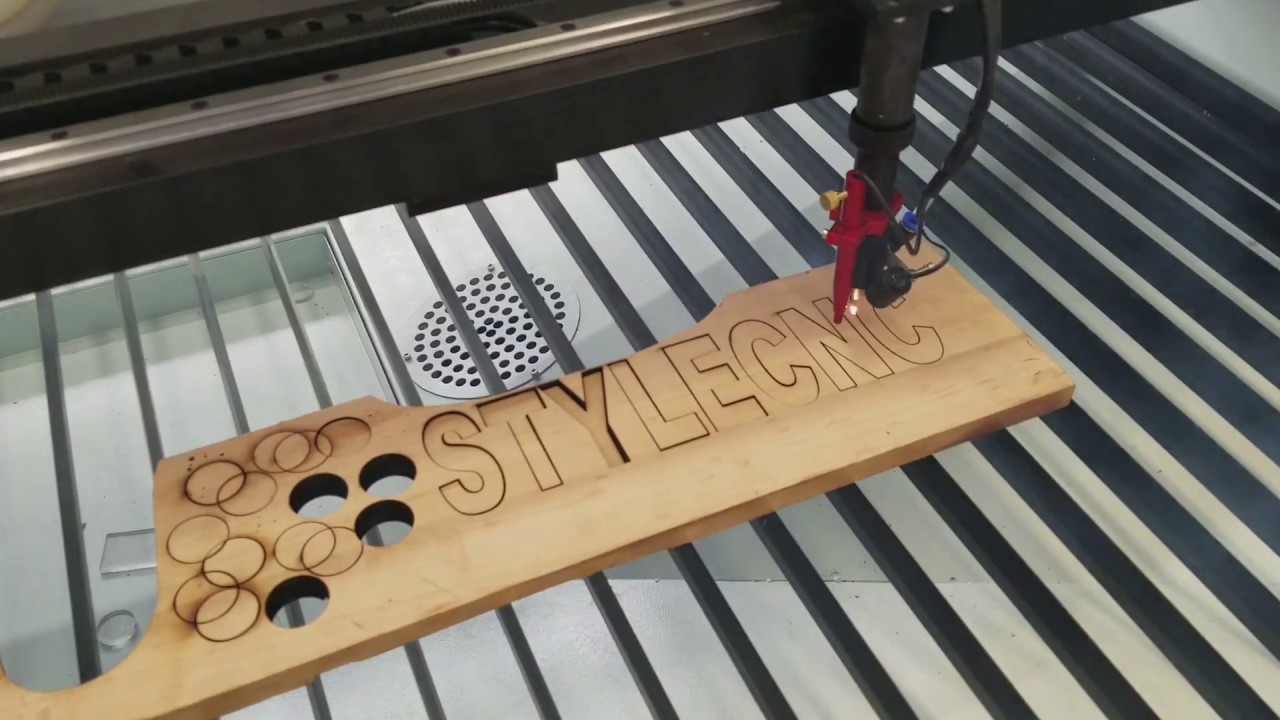

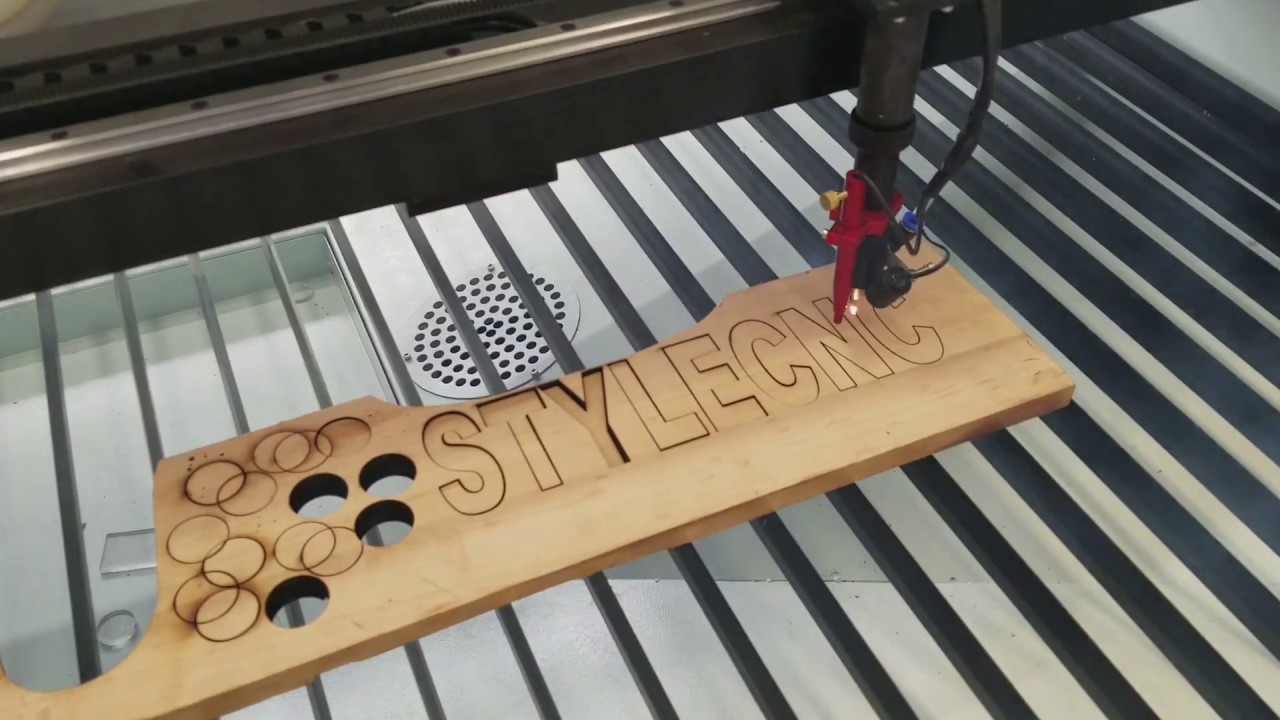

Wood Laser Cutting Machine: Precision and Versatility for Woodworking

Wood laser cutting machines have revolutionized the woodworking industry, providing unparalleled precision, efficiency, and versatility. These machines harness the power of lasers to cut, engrave, and mark wood, enabling artisans and manufacturers to create intricate designs and high-quality products with exceptional accuracy.

Advantages of Wood Laser Cutting Machines

Table of Content

- 1 Wood Laser Cutting Machine: Precision and Versatility for Woodworking

- 1.1 Advantages of Wood Laser Cutting Machines

- 1.2 Applications of Wood Laser Cutting Machines

- 1.3 Advantages of Wood Laser Cutting Machines

- 1.4 Applications of Wood Laser Cutting Machines

- 1.5 Types of Wood Laser Cutting Machines

- 1.6 Selecting the Right Wood Laser Cutting Machine

- 1.7 Conclusion

- 1.8 FAQs

Precision Cutting: Laser cutting machines utilize a highly focused laser beam to precisely cut wood, resulting in clean, smooth edges without the need for secondary finishing.

Non-Contact Cutting: Unlike traditional cutting methods, laser cutting does not require physical contact with the wood, eliminating the risk of material distortion or damage.

Speed and Efficiency: Laser cutting machines operate at high speeds, enabling rapid production of high-volume orders while maintaining consistent quality.

Applications of Wood Laser Cutting Machines

Wood laser cutting machines find applications in a wide range of industries, including:

- Furniture Making: Creating custom furniture designs, cutting intricate patterns, and engraving decorative details.

- Home Decor: Producing unique home decor items such as wall art, lamps, and decorative boxes.

- Sign Making: Cutting and engraving signs for businesses, events, and personal use.

- Musical Instruments: Crafting guitar bodies, violin scrollwork, and other musical instrument components.

- Toy Making: Creating wooden toys with intricate designs and precise cuts.

- Laser Cut Wood Houses Laser Cut Wood Houses: A Comprehensive Guide To Design, Construction, And Benefits

- Cnc Cut Wood Panels CNC Cut Wood Panels: Precision And Versatility For Diverse Applications

- Wood Laser Signs Wood Laser Signs: A Comprehensive Guide To Crafting Personalized And Eye-Catching Decor

- Wood Laser Cutouts Wood Laser Cutouts: A Versatile Solution For Diverse Applications

- Laser To Engrave Wood Laser Engraving Wood: A Comprehensive Guide

DOWNLOAD SVG FILES FOR LASER CUTTING

Advantages of Wood Laser Cutting Machines

Precision Cutting: Laser cutting machines utilize a highly focused laser beam to precisely cut wood, resulting in clean, smooth edges without the need for secondary finishing.

Intricate Designs: Lasers can create intricate and detailed designs with exceptional accuracy, making it possible to produce complex shapes and patterns with ease.

DOWNLOAD SVG FILES FOR LASER CUTTING

Non-Contact Cutting: Unlike traditional cutting methods, laser cutting does not require physical contact with the wood, eliminating the risk of material distortion or damage.

Speed and Efficiency: Laser cutting machines operate at high speeds, enabling rapid production of high-volume orders while maintaining consistent quality.

Applications of Wood Laser Cutting Machines

Types of Wood Laser Cutting Machines

There are two main types of wood laser cutting machines:

- CO2 Laser Machines: These machines use carbon dioxide lasers to cut wood, offering high power and fast cutting speeds.

- Fiber Laser Machines: These machines use fiber lasers to cut wood, providing higher precision and faster speeds than CO2 lasers.

Selecting the Right Wood Laser Cutting Machine

When selecting a wood laser cutting machine, consider the following factors:

- Power: The power of the laser determines the thickness of wood that can be cut.

- Cutting Area: Choose a machine with a cutting area large enough to accommodate the size of your projects.

- Laser Type: CO2 lasers are suitable for general-purpose cutting, while fiber lasers offer higher precision and speed.

- Software: Ensure the machine is compatible with software that supports the design and cutting process.

Conclusion

Wood laser cutting machines offer a powerful and versatile solution for woodworking, enabling the creation of intricate designs and high-quality products with precision and efficiency. By understanding the advantages, applications, and selection criteria, you can choose the right machine to meet your specific needs and elevate your woodworking capabilities.

FAQs

Q: What is the difference between CO2 and fiber laser cutting machines?

A: CO2 lasers offer high power and fast cutting speeds, while fiber lasers provide higher precision and faster speeds.

Q: What thickness of wood can wood laser cutting machines cut?

A: The thickness of wood that can be cut depends on the power of the laser.

Q: What types of wood can wood laser cutting machines cut?

A: Laser cutting machines can cut a wide range of wood types, including hardwoods, softwoods, and plywood.

Q: Is it safe to use a wood laser cutting machine?

A: Yes, laser cutting machines are generally safe to use, provided proper safety precautions are followed.