Wood Laser Cutting: A Comprehensive Guide to Precision and Versatility

Introduction

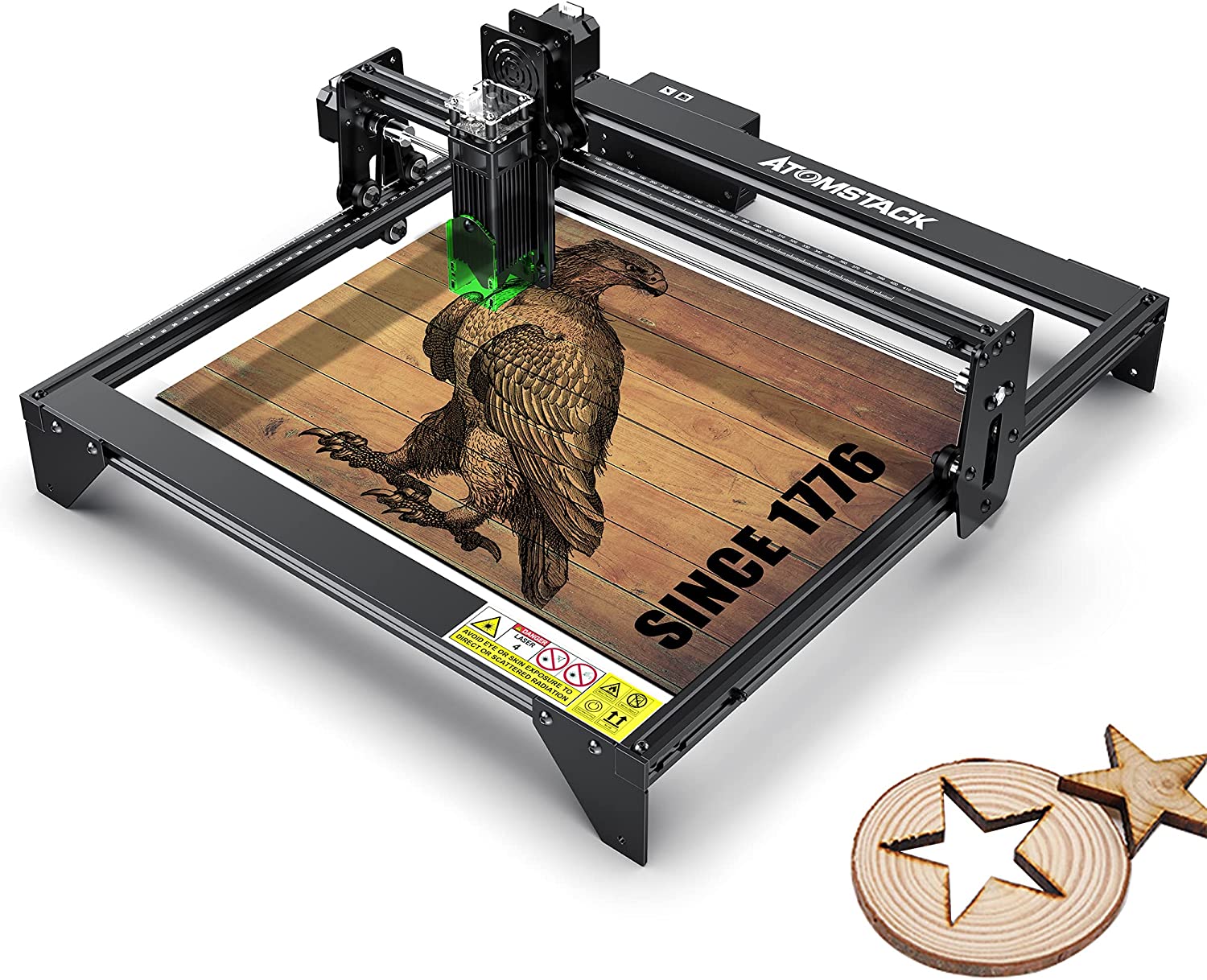

Wood laser cutting has revolutionized the manufacturing and design industries, offering unparalleled precision, versatility, and efficiency in cutting and engraving wood. This cutting-edge technology employs a focused laser beam to vaporize or melt the material, resulting in intricate and detailed designs with minimal waste. In this comprehensive guide, we delve into the world of wood laser cutting, exploring its benefits, applications, techniques, and industry advancements.

Table of Content

- 1 Wood Laser Cutting: A Comprehensive Guide to Precision and Versatility

- 1.1 Introduction

- 1.2 Benefits of Wood Laser Cutting

- 1.3 Applications of Wood Laser Cutting

- 1.4 Benefits of Wood Laser Cutting

- 1.5 Techniques in Wood Laser Cutting

- 1.6 Industry Advancements in Wood Laser Cutting

- 1.7 Conclusions

- 1.8 FAQs

Benefits of Wood Laser Cutting

- Precision: Lasers produce highly precise cuts with minimal deviation, ensuring consistent and accurate results.

- Versatility: Wood laser cutters can handle various wood types and thicknesses, allowing for a wide range of applications.

- Speed: Laser cutting is significantly faster than manual or CNC cutting, increasing productivity and efficiency.

- Minimal Waste: The focused laser beam minimizes material waste, resulting in cost savings and reduced environmental impact.

- Intricate Designs: Lasers can create complex and intricate designs that are difficult or impossible to achieve with other cutting methods.

Applications of Wood Laser Cutting

Wood laser cutting finds applications in a diverse range of industries, including:

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Wooden Laser Cut Christmas Tree Wooden Laser Cut Christmas Tree: A Unique And Eco-Friendly Holiday Decoration

- Laser Cut Wooden Animal Puzzles Laser Cut Wooden Animal Puzzles: Unlocking Educational And Creative Potential

- Laser Engraving Wood Near Me Laser Engraving Wood Near Me: A Comprehensive Guide

- Laser Cut Wooden Bowls Laser Cut Wooden Bowls: A Comprehensive Guide

- Precision: Lasers produce highly precise cuts with minimal deviation, ensuring consistent and accurate results.

- Versatility: Wood laser cutters can handle various wood types and thicknesses, allowing for a wide range of applications.

- Furniture and Home Decor: Cutting intricate designs for furniture, cabinets, decorative panels, and wall art.

- Toys and Games: Creating precise components for wooden toys, puzzles, and game boards.

- Art and Crafts: Engraving or cutting designs for artwork, sculptures, and personalized gifts.

- Industrial Products: Manufacturing wooden components for machinery, tools, and other industrial applications.

- Packaging: Cutting and engraving wooden boxes, crates, and other packaging materials.

- Vector Cutting: Cutting along predefined paths to create intricate designs with sharp edges.

- Raster Engraving: Burning or etching patterns into the wood surface, resulting in detailed images or textures.

- Combined Cutting and Engraving: Combining both techniques to create designs with both cutouts and engraved elements.

- 3D Laser Engraving: Engraving designs into the wood surface with varying depths, creating a three-dimensional effect.

- High-Power Lasers: Lasers with higher power output enable faster cutting and engraving of thicker materials.

- Ultraviolet Lasers: UV lasers offer finer and more precise cuts, ideal for intricate designs and delicate materials.

- Galvo Systems: Galvo systems provide high-speed and accurate laser beam movement, enhancing cutting efficiency.

- Software Innovations: Advanced software optimizes laser cutting parameters, reducing setup time and improving accuracy.

- Wear appropriate safety gear, including safety glasses, gloves, and respiratory protection.

- Ensure proper ventilation to remove fumes and particles.

- Keep the laser cutting area clean and free of flammable materials.

- Select hardwoods like oak or maple for durability and fine detail.

- Softwoods like pine or cedar are easier to cut but may require higher laser power.

- Consider the thickness and grain direction of the wood for optimal results.

- Regularly clean the laser lens and mirrors to prevent power loss.

- Calibrate the laser system periodically to ensure accuracy and precision.

- Replace consumable parts like nozzles and filters as needed.

Wood laser cutting has revolutionized the manufacturing and design industries, offering unparalleled precision, versatility, and efficiency in cutting and engraving wood. This cutting-edge technology employs a focused laser beam to vaporize or melt the material, resulting in intricate and detailed designs with minimal waste. In this comprehensive guide, we delve into the world of wood laser cutting, exploring its benefits, applications, techniques, and industry advancements.

Benefits of Wood Laser Cutting

Wood laser cutting offers a multitude of benefits that set it apart from traditional cutting methods:

DOWNLOAD SVG FILES FOR LASER CUTTING

Techniques in Wood Laser Cutting

Various techniques are employed in wood laser cutting to achieve specific effects:

Industry Advancements in Wood Laser Cutting

The wood laser cutting industry is constantly evolving with technological advancements:

Conclusions

Wood laser cutting has proven to be an indispensable tool in the manufacturing and design industries. Its precision, versatility, and efficiency make it ideal for a wide range of applications, from intricate furniture designs to industrial components. As technology continues to advance, wood laser cutting will continue to push the boundaries of what is possible, enabling the creation of innovative and aesthetically pleasing products.

FAQs

What are the safety considerations for wood laser cutting?

How to choose the right wood for laser cutting?

How to maintain a wood laser cutter?