Wood Metal Laser Cutter: The Ultimate Guide

Introduction

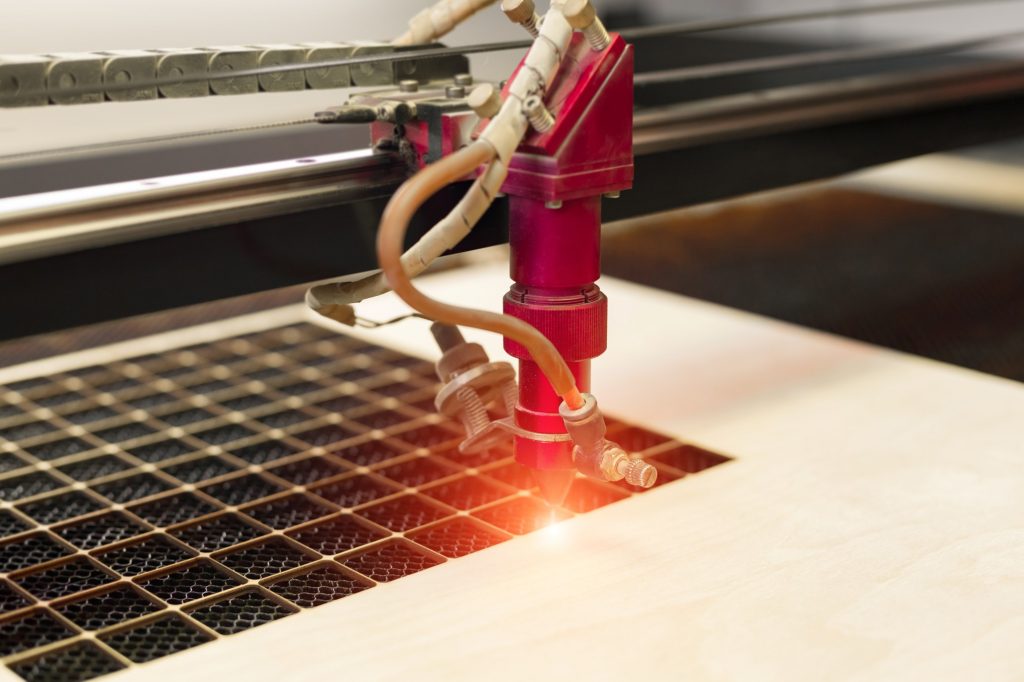

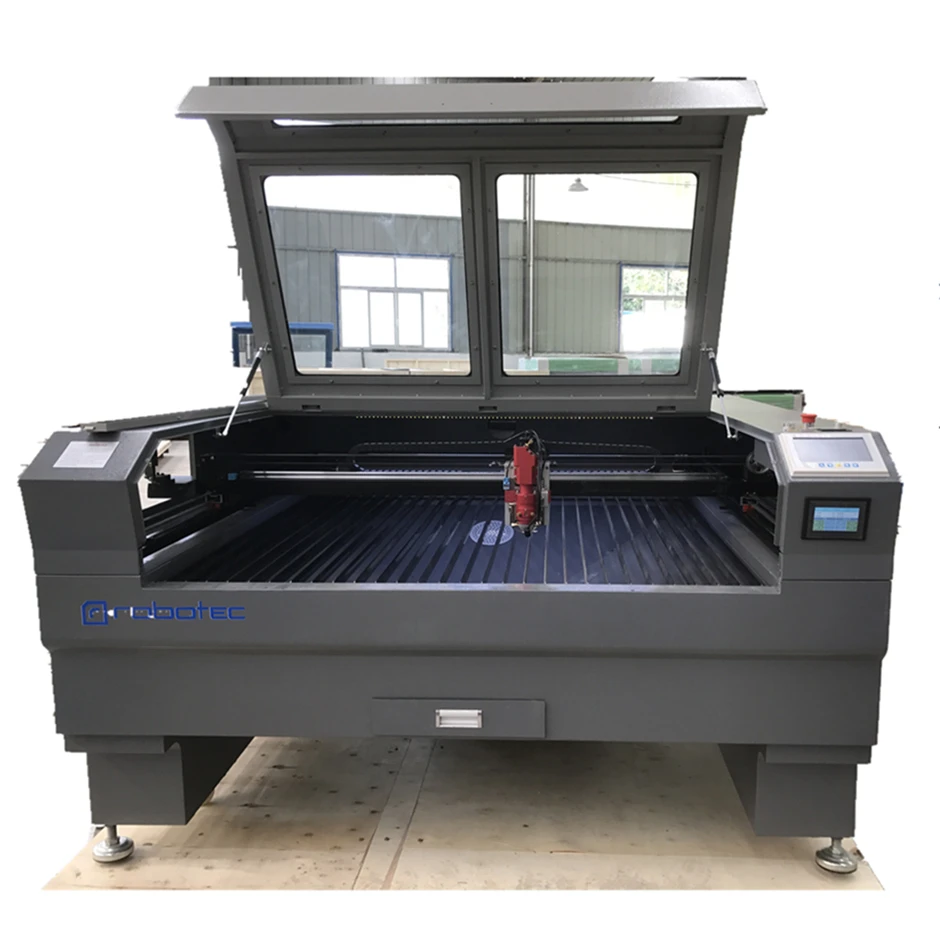

Laser cutting technology has revolutionized the manufacturing industry, enabling precise and efficient cutting of various materials, including wood and metal. Wood metal laser cutters are specifically designed to handle the unique properties of these materials, offering exceptional accuracy, speed, and versatility.

Table of Content

- 1 Wood Metal Laser Cutter: The Ultimate Guide

- 1.1 Introduction

- 1.2 Benefits of Wood Metal Laser Cutters

- 1.3 Types of Wood Metal Laser Cutters

- 1.4 Features to Consider When Choosing a Wood Metal Laser Cutter

- 1.5 Benefits of Wood Metal Laser Cutters

- 1.6 Applications of Wood Metal Laser Cutters

- 1.7 Maintenance and Safety Considerations

- 1.8 Conclusion

- 1.9 FAQs

Benefits of Wood Metal Laser Cutters

2. High Speed: Laser cutting is significantly faster than traditional cutting methods, allowing for increased productivity and reduced lead times.

3. Versatility: Wood metal laser cutters can handle a wide range of materials, including different types of wood, metal sheets, acrylics, and plastics.

4. Automation: Laser cutters can be integrated into automated systems, eliminating the need for manual labor and reducing errors.

Types of Wood Metal Laser Cutters

1. CO2 Laser Cutters: Ideal for cutting wood and thin metals, CO2 laser cutters offer high cutting speeds and excellent edge quality.

2. Fiber Laser Cutters: Designed for thicker metals and harder materials, fiber laser cutters provide faster cutting speeds and deeper penetration than CO2 lasers.

DOWNLOAD SVG FILES FOR LASER CUTTING

Features to Consider When Choosing a Wood Metal Laser Cutter

1. Laser Power: The laser power determines the thickness and type of material that can be cut. Higher laser power allows for cutting thicker materials.

2. Cutting Speed: The cutting speed determines the productivity of the laser cutter. Faster cutting speeds are desirable for high-volume production.

3. Cutting Quality: The cutting quality refers to the accuracy, smoothness, and cleanliness of the cuts. Look for laser cutters that produce high-quality cuts with minimal burrs.

Laser cutting technology has revolutionized the manufacturing industry, enabling precise and efficient cutting of various materials, including wood and metal. Wood metal laser cutters are specifically designed to handle the unique properties of these materials, offering exceptional accuracy, speed, and versatility.

- Wood Laser Cutter Designs Wood Laser Cutter Designs: Unleashing Creativity And Precision In Woodworking

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Wood Laser Cutter Wood Laser Cutter: The Ultimate Guide For Beginners And Professionals

- Best Budget Laser Wood Cutter Best Budget Laser Wood Cutters: A Comprehensive Guide For Hobbyists And Small Businesses

- Wooden Die Cut Wooden Die Cut: A Comprehensive Guide To Precision Cutting And Customization

Benefits of Wood Metal Laser Cutters

1. Precision Cutting: Laser cutters utilize a highly focused laser beam to vaporize the material, resulting in clean and precise cuts with minimal burrs or distortion.

DOWNLOAD SVG FILES FOR LASER CUTTING

2. High Speed: Laser cutting is significantly faster than traditional cutting methods, allowing for increased productivity and reduced lead times.

3. Versatility: Wood metal laser cutters can handle a wide range of materials, including different types of wood, metal sheets, acrylics, and plastics.

4. Automation: Laser cutters can be integrated into automated systems, eliminating the need for manual labor and reducing errors.

4. Material Handling: Consider the size of the cutting bed and the material handling capabilities of the laser cutter to ensure it meets your specific needs.

Applications of Wood Metal Laser Cutters

1. Woodworking: Creating intricate patterns, cutting signs, engraving designs, and prototyping wooden products.

2. Metalworking: Cutting sheet metal, fabricating parts, creating prototypes, and producing small-batch products.

3. Prototyping and Design: Laser cutters are ideal for rapid prototyping and creating custom designs in wood or metal.

4. Art and Craft: Laser cutters can be used for creating unique artwork, decorative pieces, and customized gifts.

Maintenance and Safety Considerations

1. Maintenance: Regular maintenance is crucial to ensure optimal performance and longevity of the laser cutter. Follow the manufacturer’s instructions for cleaning, lubrication, and calibration.

2. Safety: Laser cutters emit high-power laser beams, which can be hazardous. Always wear appropriate safety gear, including laser-specific goggles, and follow proper safety protocols.

Conclusion

Wood metal laser cutters offer a combination of precision, speed, versatility, and automation, making them an indispensable tool for a wide range of industries. By carefully considering the features and applications of different laser cutters, you can select the optimal machine to meet your specific needs and unlock the full potential of laser cutting technology.

FAQs

1. What are the differences between CO2 and fiber laser cutters?

CO2 laser cutters are ideal for cutting wood and thin metals, while fiber laser cutters are designed for thicker metals and harder materials.

2. How thick of material can a wood metal laser cutter cut?

The thickness of material that can be cut depends on the laser power and type of material. Typically, CO2 laser cutters can cut up to 1 inch of wood and 1/4 inch of metal, while fiber laser cutters can cut thicker materials.

3. Are wood metal laser cutters safe to use?

Laser cutters emit high-power laser beams, which can be hazardous. Always wear appropriate safety gear and follow proper safety protocols when using laser cutters.