Wooden for Laser Cut: A Comprehensive Guide to Materials, Techniques, and Applications

Introduction

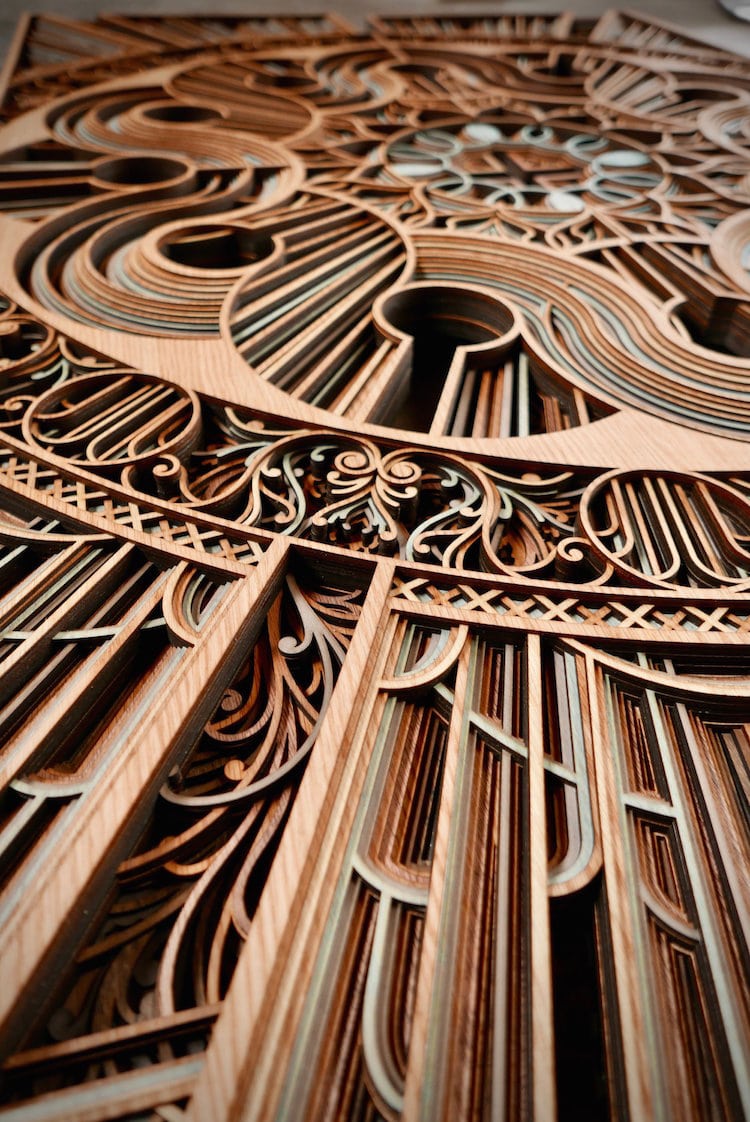

Laser cutting has emerged as a revolutionary technology in the woodworking industry, enabling the precise and efficient creation of intricate designs and complex shapes. Wooden materials offer a versatile and aesthetic base for laser cutting, allowing artisans and manufacturers to produce a wide range of products from decorative items to functional components. This comprehensive guide will delve into the intricacies of wooden for laser cut, exploring its material properties, laser cutting techniques, and diverse applications.

Table of Content

- 1 Wooden for Laser Cut: A Comprehensive Guide to Materials, Techniques, and Applications

- 1.1 Introduction

- 1.2 H1: Material Properties of Wooden for Laser Cut

- 1.3 H1: Material Properties of Wooden for Laser Cut

- 1.4 H1: Laser Cutting Techniques for Wooden

- 1.5 H1: Applications of Wooden for Laser Cut

- 1.6 Conclusion

- 1.7 FAQs

H1: Material Properties of Wooden for Laser Cut

The type of wood used for laser cutting significantly influences the final product’s appearance, durability, and cutting characteristics. Common wood species for laser cutting include:

- Hardwoods: Oak, mahogany, walnut, and cherry are known for their strength, durability, and intricate grain patterns.

- Softwoods: Pine, cedar, and fir are softer and more economical, making them suitable for larger projects or where strength is not a primary concern.

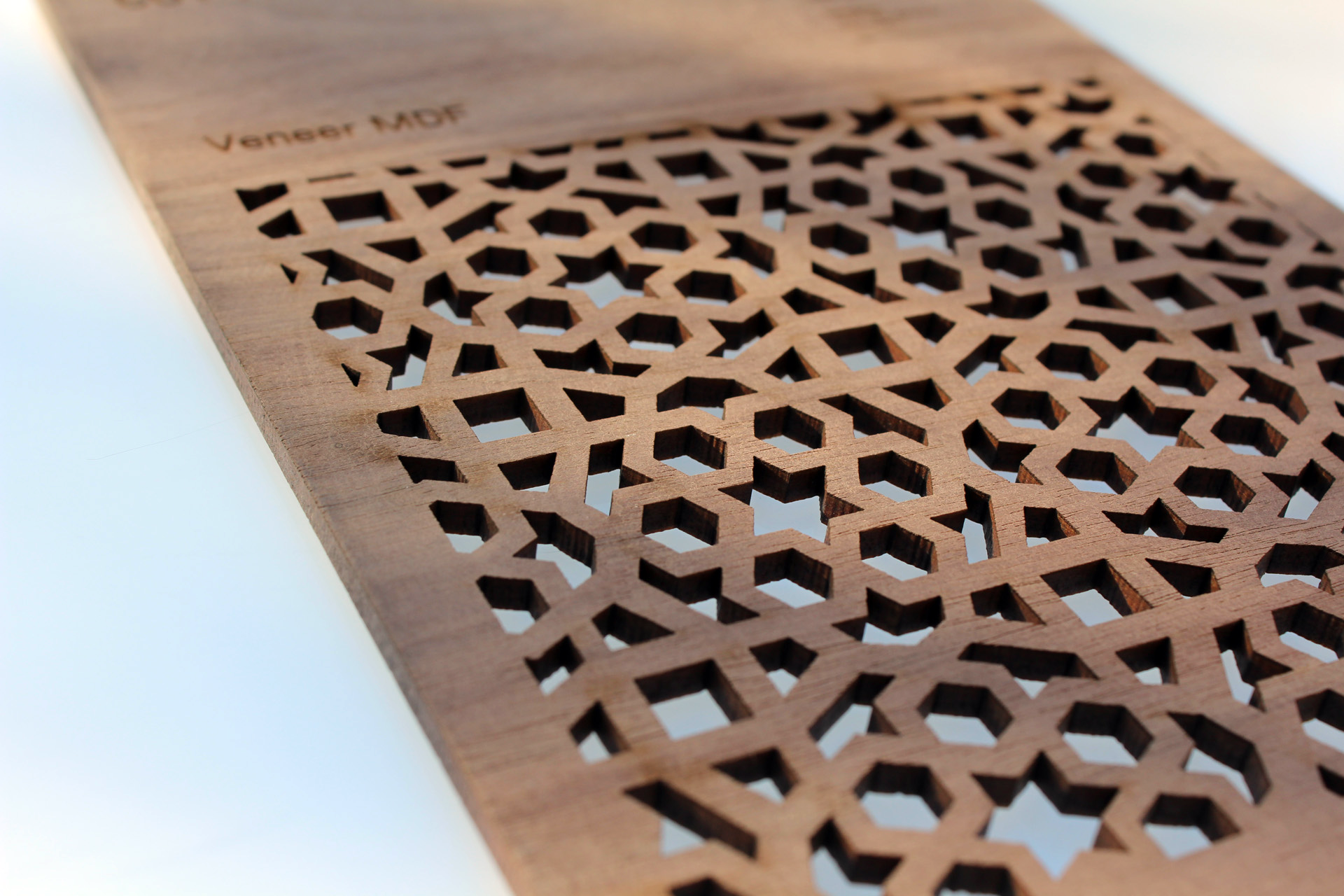

- Engineered Woods: Plywood, MDF, and particle board offer uniform thickness and consistency, reducing the likelihood of warping or cracking during laser cutting.

DOWNLOAD SVG FILES FOR LASER CUTTING

2. Grain Orientation

The grain orientation of the wood refers to the direction of the wood fibers. Cutting with the grain (parallel to the fibers) results in cleaner cuts and less charring, while cutting against the grain (perpendicular to the fibers) can produce a more textured or distressed finish.

3. Moisture Content

The moisture content of the wood is crucial for laser cutting. Dry wood is less likely to warp or crack during the cutting process, ensuring precision and minimizing waste. The ideal moisture content for laser cutting typically ranges from 6% to 12%.

Laser cutting has emerged as a revolutionary technology in the woodworking industry, enabling the precise and efficient creation of intricate designs and complex shapes. Wooden materials offer a versatile and aesthetic base for laser cutting, allowing artisans and manufacturers to produce a wide range of products from decorative items to functional components. This comprehensive guide will delve into the intricacies of wooden for laser cut, exploring its material properties, laser cutting techniques, and diverse applications.

- Moroccan Laser Cut Wood Moroccan Laser Cut Wood: A Timeless Art With Modern Applications

- Laser Cut Folding Wood Laser Cut Folding Wood: A Comprehensive Guide

- Laser Branding Wood Laser Branding Wood: A Comprehensive Guide

- Cricut Wood Etching Cricut Wood Etching: A Comprehensive Guide For Beginners And Experts

- Best Wood For Glowforge Best Wood For Glowforge: A Comprehensive Guide To Choosing The Perfect Material

H1: Material Properties of Wooden for Laser Cut

1. Wood Species

DOWNLOAD SVG FILES FOR LASER CUTTING

The type of wood used for laser cutting significantly influences the final product’s appearance, durability, and cutting characteristics. Common wood species for laser cutting include:

- Hardwoods: Oak, mahogany, walnut, and cherry are known for their strength, durability, and intricate grain patterns.

- CO2 Lasers: Best suited for cutting thick hardwoods and producing clean, polished edges.

- Fiber Lasers: Ideal for cutting thin woods and producing high-speed cuts with minimal heat distortion.

- Diode Lasers: Suitable for low-power cutting of thin woods, often used for engraving and detail work.

- Vector Cutting: Creates precise lines and shapes by following a predetermined path.

- Raster Cutting: Scans the laser beam over the surface to produce detailed engravings or images.

- Perforation Cutting: Creates a series of holes to reduce material thickness or create decorative patterns.

- Intricate wall art

- Personalized home accessories

- Custom furniture and cabinetry

- Jewelry and accessories

- Scrapbooking and papercraft

- Model making and prototyping

- Precision components for manufacturing

- Architectural models

- Packaging and display products

H1: Laser Cutting Techniques for Wooden

1. Laser Types

The type of laser used for cutting wood depends on the desired results and the specific wood material. Common laser types include:

2. Cutting Parameters

The laser cutting parameters, including power, speed, and focal distance, must be carefully adjusted to optimize the cutting process. Higher power settings result in deeper cuts, while faster speeds reduce the heat input and minimize charring. The focal distance affects the beam’s focus and can influence the cut quality.

3. Cutting Techniques

Various cutting techniques can be employed for wooden, including:

H1: Applications of Wooden for Laser Cut

The versatility of wooden for laser cut opens up a wide range of applications across various industries:

1. Home Decor

2. Arts and Crafts

3. Industrial Applications

Conclusion

Wooden for laser cut is a versatile and aesthetically pleasing material that enables the creation of intricate designs and complex shapes. Understanding the material properties, laser cutting techniques, and diverse applications of wooden for laser cut empowers artisans and manufacturers to produce a wide range of products with precision, efficiency, and creativity.

FAQs

1. What is the best wood for laser cutting?

The best wood for laser cutting depends on the desired results. Hardwoods provide strength and durability, while softwoods are more economical. Engineered woods offer uniform thickness and consistency.

2. How do I prevent warping and cracking during laser cutting?

Ensure the wood has a low moisture content, typically between 6% and 12%. Use appropriate cutting parameters to minimize heat input and stress on the wood.

3. Can I cut wood with a diode laser?

Yes, diode lasers can cut thin woods, but they are primarily used for engraving and detail work. CO2 and fiber lasers are better suited for cutting thicker woods.