Wooden Laser Cut Panels: A Comprehensive Guide

Introduction

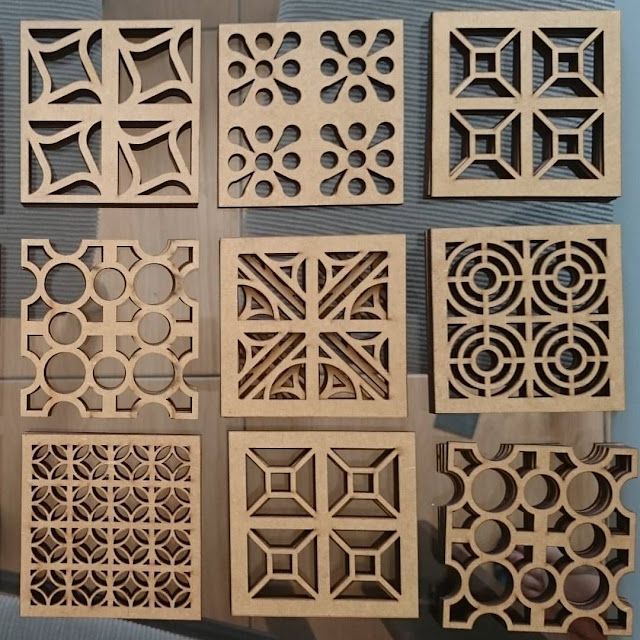

Wooden laser cut panels are versatile and aesthetically pleasing materials that have gained immense popularity in various industries. They offer a unique combination of precision, durability, and customization, making them ideal for a wide range of applications. This comprehensive guide will explore the benefits, types, applications, and fabrication process of wooden laser cut panels.

Table of Content

- 1 Wooden Laser Cut Panels: A Comprehensive Guide

- 1.1 Introduction

- 2 Benefits of Wooden Laser Cut Panels

- 3 Types of Wooden Laser Cut Panels

- 4 Benefits of Wooden Laser Cut Panels

- 4.2 Applications of Wooden Laser Cut Panels

- 5 Fabrication Process of Wooden Laser Cut Panels

- 5.3 Design Considerations

- 6 Conclusion

- 6.4 FAQs

Benefits of Wooden Laser Cut Panels

DOWNLOAD SVG FILES FOR LASER CUTTING

Types of Wooden Laser Cut Panels

Based on the wood species used, wooden laser cut panels can be classified into:

- Hardwood Panels: Made from hardwoods such as oak, maple, and walnut, these panels offer exceptional strength and durability.

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Wooden Laser Cut Models H1: Unleashing The Precision And Creativity Of Wooden Laser Cut Models

- Wood To Laser Cut Wood To Laser Cut: A Comprehensive Guide

- Mini Laser Cut Wood Shapes Mini Laser Cut Wood Shapes: A Comprehensive Guide To Precision And Versatility

- Portable Wood Laser Engraver Portable Wood Laser Engraver: The Ultimate Guide To Unleashing Your Creativity

- Precision Cutting: Laser cutting technology allows for intricate and precise cuts, resulting in panels with clean edges and sharp corners.

- Durable and Long-Lasting: Wood is a naturally durable material, and laser cutting enhances its strength and resistance to warping or cracking.

- Versatile Applications: Wooden laser cut panels can be used in a variety of settings, including furniture, signage, architectural elements, and decorative pieces.

- Softwood Panels: Derived from softwoods like pine, fir, and spruce, these panels are more lightweight and cost-effective.

- Plywood Panels: Consisting of multiple layers of wood glued together, plywood panels provide increased stability and resistance to moisture.

- MDF Panels: Made from compressed wood fibers, MDF panels are smooth and easy to cut, making them suitable for intricate designs.

- Furniture: Decorative panels for tables, chairs, cabinets, and headboards.

- Signage: Custom signs for businesses, events, and wayfinding systems.

- Architectural Elements: Decorative wall panels, ceiling tiles, and screens.

- Decorative Pieces: Artwork, wall hangings, and home accessories.

- Industrial Applications: Jigs, fixtures, and packaging components.

- Material Selection: Choosing the appropriate wood species based on the desired properties and application.

- Design Creation: Designing the panel’s shape, pattern, and dimensions using CAD software.

- Laser Cutting: Using a laser cutter to precisely cut the wood according to the design.

- Finishing: Sanding, staining, or painting the panel to enhance its appearance and protect it from the elements.

- Material Thickness: The thickness of the wood will affect the panel’s strength and rigidity.

- Cut Path: The path of the laser cutter should be optimized to minimize material waste and ensure a clean cut.

- Kerf Width: The width of the laser’s cut will determine the accuracy and precision of the panel’s dimensions.

- Grain Direction: The grain direction of the wood can affect the panel’s strength and appearance.

- Finishing Techniques: The type of finish applied to the panel will determine its durability and aesthetic appeal.

Wooden laser cut panels are versatile and aesthetically pleasing materials that have gained immense popularity in various industries. They offer a unique combination of precision, durability, and customization, making them ideal for a wide range of applications. This comprehensive guide will explore the benefits, types, applications, and fabrication process of wooden laser cut panels.

Benefits of Wooden Laser Cut Panels

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of Wooden Laser Cut Panels

Fabrication Process of Wooden Laser Cut Panels

The fabrication process of wooden laser cut panels involves several steps:

Design Considerations

When designing wooden laser cut panels, it is important to consider:

Conclusion

Wooden laser cut panels are versatile materials that offer numerous benefits and applications. Their precision cutting, durability, and customization capabilities make them an ideal choice for a variety of industries. By understanding the different types, fabrication process, and design considerations, you can effectively utilize wooden laser cut panels to create unique and visually appealing projects.

FAQs

Q: What is the difference between hardwood and softwood laser cut panels?

A: Hardwood panels are more durable and strong, while softwood panels are lighter and more cost-effective.

Q: Can wooden laser cut panels be painted or stained?

A: Yes, wooden laser cut panels can be painted or stained to enhance their appearance and protect them from the elements.

Q: What are the common applications of wooden laser cut panels?

A: Wooden laser cut panels are commonly used in furniture, signage, architectural elements, decorative pieces, and industrial applications.

Q: How do I choose the right material thickness for my laser cut panel?

A: The appropriate material thickness depends on the desired strength, rigidity, and application of the panel.

Q: What is the typical kerf width of a laser cutter?

A: The kerf width varies depending on the laser cutter’s power and the material being cut. It typically ranges from 0.005 to 0.02 inches.