Wooden Laser Cut: A Comprehensive Guide

Introduction

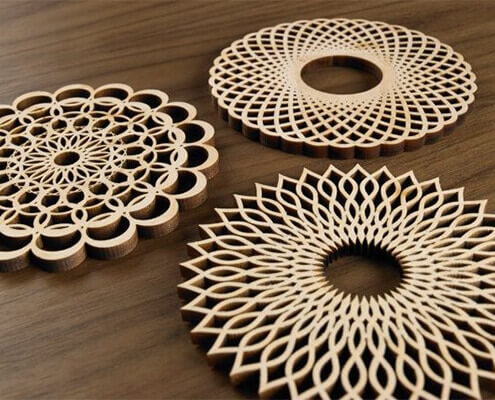

Laser cutting is a versatile manufacturing technique that utilizes a high-powered laser to precisely cut or engrave materials. When applied to wood, laser cutting offers numerous advantages, making it a popular choice for various applications. This comprehensive guide explores the intricacies of wooden laser cutting, from its benefits to its limitations and practical applications.

Table of Content

- 1 Wooden Laser Cut: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Benefits of Wooden Laser Cut

- 1.2.1 Versatility

- 1.2.2 Speed and Efficiency

- 1.2.3 Non-Contact Process

- 1.2.4 Customization and Personalization

- 1.3 Limitations of Wooden Laser Cut

- 1.4 Benefits of Wooden Laser Cut

- 1.4.5 Precision and Accuracy

- 1.4.6 Versatility

- 1.4.7 Material Thickness

- 1.4.8 Smoke and Fumes

- 1.4.9 Cost

- 1.5 Applications of Wooden Laser Cut

- 1.5.10 Home Décor

- 1.5.11 Signage

- 1.5.12 Toys and Games

- 1.5.13 Industrial Applications

- 1.6 Conclusion

- 1.7 FAQs

Benefits of Wooden Laser Cut

Laser cutting boasts exceptional precision, enabling intricate designs and precise cuts with minimal deviations. This accuracy ensures high-quality products and reduces the need for manual adjustments or post-processing.

Versatility

Laser cutting can process a wide range of wood species, including hardwoods, softwoods, and engineered wood. This versatility allows for the creation of products with varying characteristics and applications.

Speed and Efficiency

Laser cutting is a relatively fast process, especially for intricate designs that would be time-consuming to cut manually. The high speed of laser cutting enhances production efficiency and reduces lead times.

Non-Contact Process

DOWNLOAD SVG FILES FOR LASER CUTTING

Unlike traditional cutting methods, laser cutting does not require direct contact with the material. This non-contact process minimizes material deformation and ensures clean, burr-free cuts.

Customization and Personalization

Laser cutting enables the creation of customized and personalized products. From unique home décor to personalized gifts, laser cutting allows for the creation of one-of-a-kind items.

Limitations of Wooden Laser Cut

Laser cutting is a versatile manufacturing technique that utilizes a high-powered laser to precisely cut or engrave materials. When applied to wood, laser cutting offers numerous advantages, making it a popular choice for various applications. This comprehensive guide explores the intricacies of wooden laser cutting, from its benefits to its limitations and practical applications.

Benefits of Wooden Laser Cut

Precision and Accuracy

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting boasts exceptional precision, enabling intricate designs and precise cuts with minimal deviations. This accuracy ensures high-quality products and reduces the need for manual adjustments or post-processing.

Versatility

Laser cutting can process a wide range of wood species, including hardwoods, softwoods, and engineered wood. This versatility allows for the creation of products with varying characteristics and applications.

Material Thickness

While laser cutting can process a wide range of wood thicknesses, there is a limit to the thickness that can be cut. The maximum thickness varies depending on the laser power and the type of wood being cut.

Smoke and Fumes

Laser cutting wood produces smoke and fumes that may require ventilation or extraction systems to ensure a safe working environment.

Cost

Laser cutting equipment and materials can be relatively expensive, which may limit its accessibility for small-scale operations or hobbyists.

Applications of Wooden Laser Cut

Home Décor

Laser cutting is widely used in the creation of home décor items, such as wall art, furniture, and lighting fixtures. The intricate designs and precise cuts add a touch of elegance and sophistication to any living space.

Signage

Laser cutting is ideal for creating custom signage, from business logos to directional signs. The durability and weather resistance of laser-cut wood make it suitable for both indoor and outdoor applications.

Toys and Games

Laser cutting is a popular choice for manufacturing toys and games. The precision and versatility of laser cutting allow for the creation of intricate and engaging toys that meet safety standards.

Industrial Applications

Laser cutting is also used in industrial applications, such as cutting components for furniture, packaging, and musical instruments. The speed and efficiency of laser cutting enhance productivity and reduce production costs.

Conclusion

Wooden laser cutting offers a range of benefits, including precision, versatility, speed, and customization. While there are some limitations to consider, such as material thickness and cost, laser cutting remains a valuable manufacturing technique for a wide range of applications. From home décor to industrial products, laser cutting empowers creators and businesses to bring their designs to life with precision and efficiency.

FAQs

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness of wood that can be laser cut depends on the laser power and the type of wood being cut. Generally, laser cutters can cut wood up to a thickness of 0.5 inches (12.7 mm).

Q: What types of wood can be laser cut?

A: Laser cutting can process a wide range of wood species, including hardwoods, softwoods, and engineered wood. Some of the most commonly used woods for laser cutting include birch, maple, cherry, and MDF.

Q: Is laser cutting wood safe?

A: Laser cutting wood produces smoke and fumes, which may require ventilation or extraction systems to ensure a safe working environment. It is important to follow safety guidelines and use appropriate personal protective equipment.