Wooden Laser Cutting Design: A Comprehensive Guide

Introduction

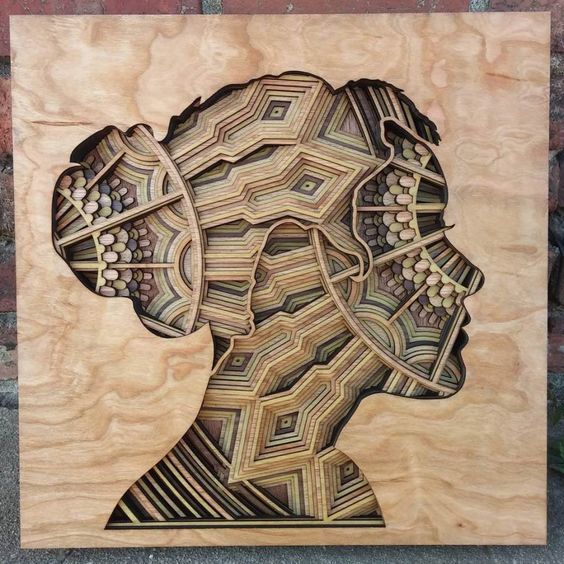

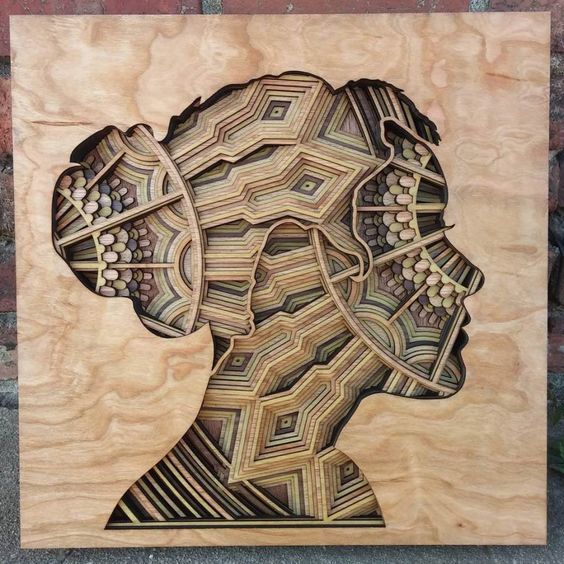

Laser cutting technology has revolutionized the woodworking industry, enabling intricate designs and precise cuts with unparalleled accuracy. Wooden laser cutting offers a wide range of possibilities for creating unique and functional objects, from home décor to industrial components. This comprehensive guide will explore the world of wooden laser cutting design, providing a detailed overview of techniques, applications, and best practices.

Table of Content

- 1 Wooden Laser Cutting Design: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Techniques of Wooden Laser Cutting

- 1.3 Applications of Wooden Laser Cutting

- 1.4 Techniques of Wooden Laser Cutting

- 1.5 Design Considerations for Wooden Laser Cutting

- 1.6 Best Practices for Wooden Laser Cutting

- 1.7 Conclusion

- 1.8 FAQs

Techniques of Wooden Laser Cutting

Vector cutting is the most common method of laser cutting wood. It involves directing a laser beam along a predefined path, creating precise and clean cuts. The laser beam vaporizes the wood along the cut line, resulting in smooth edges and sharp corners.

Raster Engraving

Raster engraving uses a raster pattern to create images or text on wood surfaces. The laser beam moves across the wood in a series of parallel lines, varying the laser power to produce different shades and textures. Raster engraving allows for detailed designs with intricate shading.

Perforation

Perforation creates a series of small holes in the wood, producing a lace-like effect. It is often used for decorative purposes or to reduce the weight of the material.

Applications of Wooden Laser Cutting

DOWNLOAD SVG FILES FOR LASER CUTTING

Home Décor

Laser cutting is widely used in home décor applications, such as custom furniture, wall art, and lighting fixtures. The ability to create intricate designs and precise cuts makes it ideal for creating unique and stylish pieces that complement any décor style.

Industrial Components

Wooden laser cutting also finds applications in industrial settings, such as the production of prototypes, packaging materials, and components for machinery. The precision and speed of laser cutting make it a cost-effective solution for producing high-quality industrial components.

Laser cutting technology has revolutionized the woodworking industry, enabling intricate designs and precise cuts with unparalleled accuracy. Wooden laser cutting offers a wide range of possibilities for creating unique and functional objects, from home décor to industrial components. This comprehensive guide will explore the world of wooden laser cutting design, providing a detailed overview of techniques, applications, and best practices.

- Best Laser For Wood Engraving Best Laser For Wood Engraving: A Comprehensive Guide To Choosing The Right Tool

- Custom Laser Cut Wood Panels Custom Laser Cut Wood Panels: Elevate Your Designs With Precision And Versatility

- Laser Cut Wood Plaque Laser Cut Wood Plaques: A Comprehensive Guide To Customization And Design

- Laser Engraving Wood Near Me Laser Engraving Wood Near Me: A Comprehensive Guide

- Laser Cut Wood Panels Near Me Laser Cut Wood Panels Near Me: A Comprehensive Guide

Techniques of Wooden Laser Cutting

Vector Cutting

DOWNLOAD SVG FILES FOR LASER CUTTING

Vector cutting is the most common method of laser cutting wood. It involves directing a laser beam along a predefined path, creating precise and clean cuts. The laser beam vaporizes the wood along the cut line, resulting in smooth edges and sharp corners.

Raster Engraving

Raster engraving uses a raster pattern to create images or text on wood surfaces. The laser beam moves across the wood in a series of parallel lines, varying the laser power to produce different shades and textures. Raster engraving allows for detailed designs with intricate shading.

Toys and Games

Laser cutting is an excellent technique for creating custom toys and games. The ability to cut complex shapes and engrave intricate details allows for the production of unique and engaging playthings.

Design Considerations for Wooden Laser Cutting

Wood Selection

The type of wood used for laser cutting plays a crucial role in the final product. Hardwoods, such as oak and maple, produce clean cuts and are suitable for intricate designs. Softwoods, such as pine and cedar, are easier to cut but may produce more charring.

Laser Power and Speed

The power and speed of the laser beam must be adjusted according to the thickness and density of the wood. Higher power and slower speeds produce cleaner cuts, while lower power and faster speeds may result in more charring.

Vectorization

Vectorizing is the process of converting images or text into a vector format, which is required for laser cutting. The accuracy of the vectorization process is essential for achieving precise cuts and smooth edges.

Best Practices for Wooden Laser Cutting

Ventilation

Laser cutting wood produces fumes, so it is crucial to ensure proper ventilation during the process. A fume extractor or exhaust system should be used to remove harmful gases from the work area.

Laser Focus

The laser beam must be properly focused to achieve clean cuts. The optimal focus depends on the thickness of the wood and the laser power.

Hold-Downs

Hold-downs are used to keep the wood in place during the cutting process. This prevents the wood from moving and ensures accurate cuts.

Cleanliness

The laser cutting bed and lens should be kept clean to prevent debris buildup. This ensures consistent beam quality and prevents damage to the laser system.

Conclusion

Wooden laser cutting design offers a vast array of possibilities for creating unique and functional objects. By understanding the techniques, applications, and best practices outlined in this guide, you can harness the power of laser cutting to produce stunning designs with unparalleled precision. Whether you are a hobbyist or a professional, wooden laser cutting is a versatile and rewarding craft that can bring your creative visions to life.

FAQs

Q: What is the best type of wood for laser cutting?

A: Hardwoods, such as oak and maple, are ideal for laser cutting due to their clean cuts and ability to handle intricate designs.

Q: How do I ventilate my workspace for laser cutting?

A: Use a fume extractor or exhaust system to remove harmful gases produced during the cutting process.

Q: How do I ensure precise cuts with laser cutting?

A: Proper vectorization, laser focus, and the use of hold-downs are essential for achieving accurate and clean cuts.

Q: Can I cut other materials besides wood with a laser cutter?

A: Yes, laser cutters can also cut a variety of other materials, such as acrylic, leather, and fabric. However, the specific materials that can be cut depend on the laser system and its capabilities.

Q: How do I maintain my laser cutting system?

A: Regular cleaning of the laser cutting bed and lens, as well as proper maintenance of the laser system, are crucial for optimal performance and longevity.