H1: Unveiling the Versatility of Wooden Sheets for Laser Cutting: A Comprehensive Guide

H2: Introduction

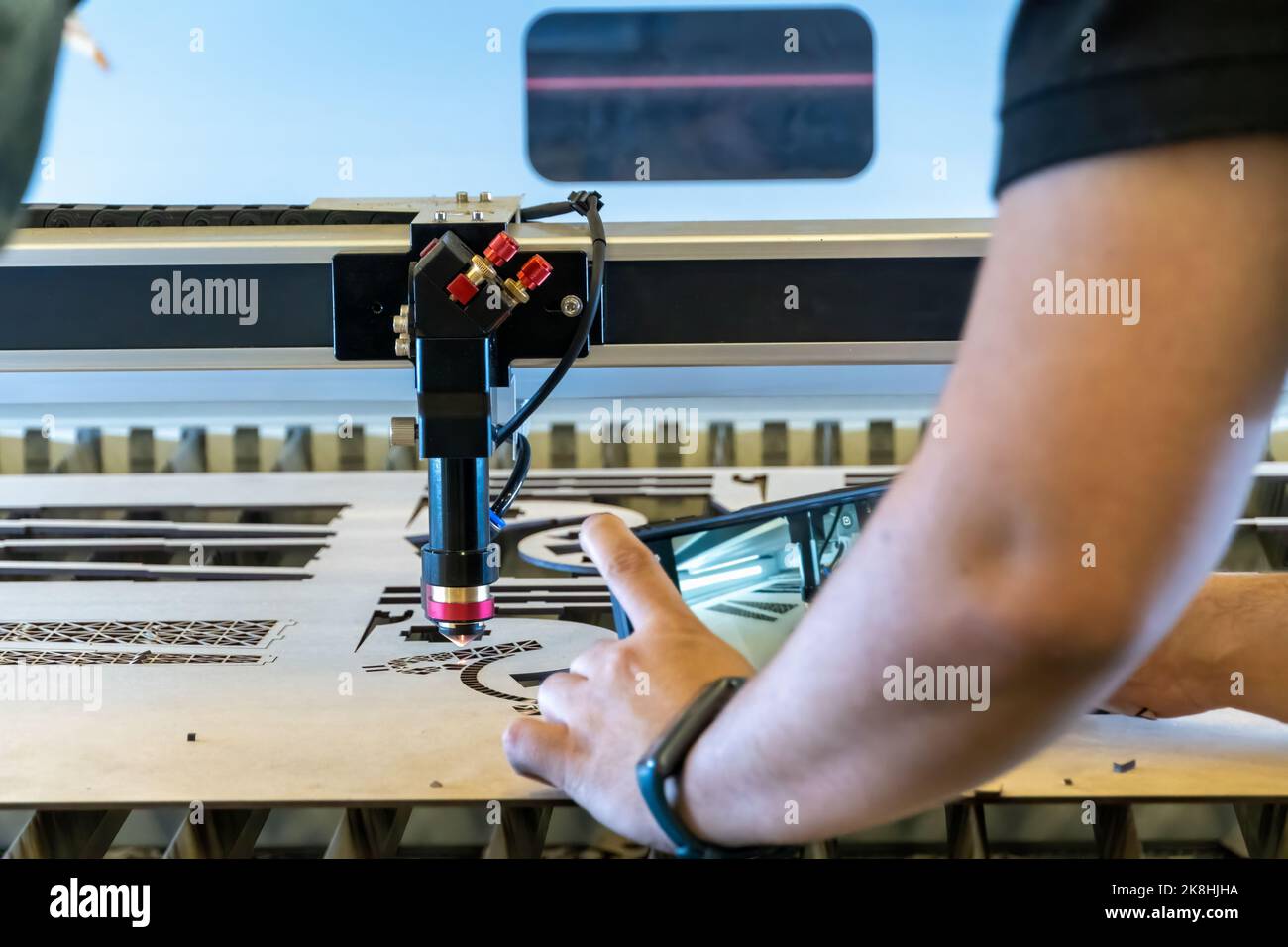

Laser cutting technology has revolutionized the manufacturing industry, enabling precise and intricate designs on a wide range of materials. Among these materials, wooden sheets have emerged as a versatile option, offering unique advantages for a diverse range of applications. This article delves into the world of wooden sheets for laser cutting, exploring their properties, benefits, and practical uses.

Table of Content

- 1 H1: Unveiling the Versatility of Wooden Sheets for Laser Cutting: A Comprehensive Guide

- 1.1 H2: Introduction

- 2 H2: Properties of Wooden Sheets for Laser Cutting

- 2.2 H2.2: Thickness and Grain Patterns

- 2.3 H2.3: Surface Quality and Finishing

- 3 H2: Benefits of Laser Cutting Wooden Sheets

- 3.4 H2.1: Precision and Intricacy

- 3.5 H2.2: Clean and Burr-Free Cuts

- 4 H2: Properties of Wooden Sheets for Laser Cutting

- 4.6 H2.1: Material Composition

- 4.7 H2.2: Thickness and Grain Patterns

- 4.8 H2.3: Versatility and Customization

- 5 H2: Applications of Laser-Cut Wooden Sheets

- 5.9 H2.1: Decorative Arts and Crafts

- 5.10 H2.2: Architectural Elements

- 5.11 H2.3: Industrial Applications

- 6 H2: Conclusion

- 7 H3: FAQs

H2: Properties of Wooden Sheets for Laser Cutting

Wooden sheets for laser cutting are typically made from various types of wood, including plywood, MDF (Medium Density Fiberboard), and HDF (High Density Fiberboard). These materials consist of wood fibers bonded together with adhesives or resins, resulting in sheets that are both durable and lightweight.

H2.2: Thickness and Grain Patterns

Wooden sheets come in a range of thicknesses, from thin veneers to thicker planks. The thickness of the sheet determines its strength and suitability for different applications. Additionally, wooden sheets exhibit natural grain patterns, which can enhance the aesthetic appeal of laser-cut designs.

H2.3: Surface Quality and Finishing

Wooden sheets can have various surface finishes, such as sanded, smooth, or textured. The surface quality influences the precision and detail of laser-cut designs. Post-processing techniques like sanding or staining can further enhance the appearance and durability of the finished product.

H2: Benefits of Laser Cutting Wooden Sheets

DOWNLOAD SVG FILES FOR LASER CUTTING

H2.1: Precision and Intricacy

Laser cutting offers unparalleled precision and accuracy, allowing for complex designs and intricate cuts with minimal waste. This makes wooden sheets ideal for applications requiring high levels of detail, such as decorative panels, signage, and model making.

H2.2: Clean and Burr-Free Cuts

Unlike traditional cutting methods, laser cutting produces clean and burr-free edges on wooden sheets. This eliminates the need for additional finishing steps, saving time and effort. The laser’s focused beam also minimizes charring and discoloration, resulting in a high-quality finish.

Laser cutting technology has revolutionized the manufacturing industry, enabling precise and intricate designs on a wide range of materials. Among these materials, wooden sheets have emerged as a versatile option, offering unique advantages for a diverse range of applications. This article delves into the world of wooden sheets for laser cutting, exploring their properties, benefits, and practical uses.

- Wooden Laser Cut Gifts Wooden Laser Cut Gifts: A Timeless Expression Of Creativity And Thoughtfulness

- Laser Cut Wooden Necklace Laser Cut Wooden Necklace: A Timeless Accessory For Style And Sentiment

- Laser Cut Wooden Bow Tie Laser Cut Wooden Bow Tie: A Stylish And Sustainable Accessory

- Laser Cut Wooden Tree Shapes H1: Laser Cut Wooden Tree Shapes: Elevate Your Décor With Nature’s Charm

- Wooden Laser Cut Magnet Wooden Laser Cut Magnets: A Unique And Customizable Way To Display Your Memories

H2: Properties of Wooden Sheets for Laser Cutting

H2.1: Material Composition

DOWNLOAD SVG FILES FOR LASER CUTTING

Wooden sheets for laser cutting are typically made from various types of wood, including plywood, MDF (Medium Density Fiberboard), and HDF (High Density Fiberboard). These materials consist of wood fibers bonded together with adhesives or resins, resulting in sheets that are both durable and lightweight.

H2.2: Thickness and Grain Patterns

Wooden sheets come in a range of thicknesses, from thin veneers to thicker planks. The thickness of the sheet determines its strength and suitability for different applications. Additionally, wooden sheets exhibit natural grain patterns, which can enhance the aesthetic appeal of laser-cut designs.

H2.3: Versatility and Customization

Wooden sheets can be laser-cut into a wide range of shapes and sizes, making them suitable for various applications. From intricate designs to functional components, laser cutting enables the creation of customized products tailored to specific needs.

H2: Applications of Laser-Cut Wooden Sheets

H2.1: Decorative Arts and Crafts

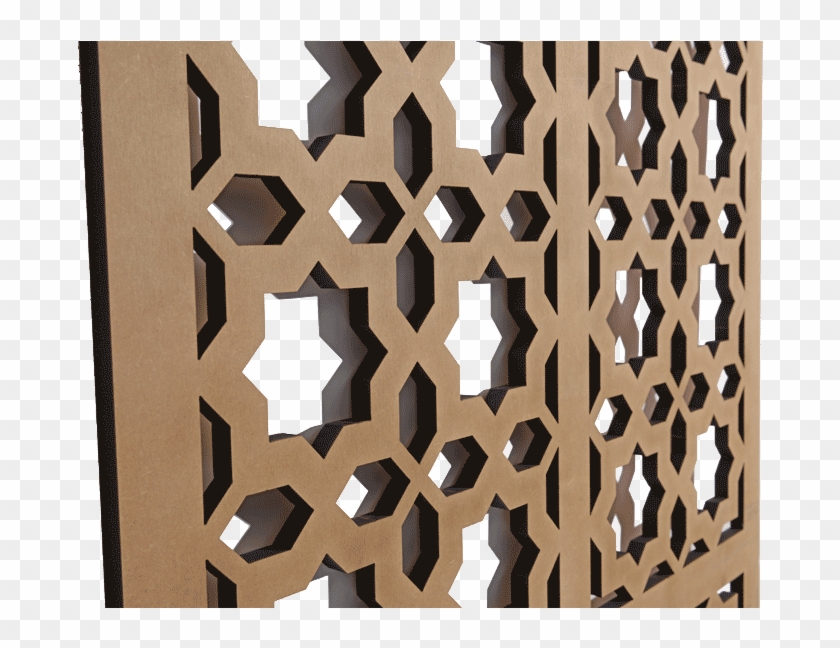

Laser-cut wooden sheets are extensively used in decorative arts and crafts. They can be transformed into intricate wall art, decorative panels, and custom furniture pieces. The natural beauty of wood combined with the precision of laser cutting creates unique and eye-catching designs.

H2.2: Architectural Elements

Laser-cut wooden sheets find application in architectural elements such as screens, dividers, and ceiling panels. These sheets can be cut into complex geometric patterns, creating visually stunning and functional spaces. The lightweight and durable nature of wooden sheets makes them ideal for these applications.

H2.3: Industrial Applications

Laser-cut wooden sheets are also utilized in industrial applications, including prototyping, model making, and packaging. The ability to create precise and intricate parts makes wooden sheets suitable for creating functional components and mock-ups for product development.

H2: Conclusion

Wooden sheets for laser cutting offer a myriad of benefits, including precision, versatility, and aesthetic appeal. Their unique properties make them suitable for a wide range of applications, from decorative arts and crafts to architectural elements and industrial uses. As laser cutting technology continues to advance, the potential for wooden sheets as a cutting-edge material is limitless.

H3: FAQs

Q: What is the best type of wood for laser cutting?

A: The ideal wood for laser cutting depends on the desired application. Plywood, MDF, and HDF are commonly used due to their durability and versatility.

Q: How thick can wooden sheets be laser-cut?

A: The thickness of laser-cut wooden sheets varies depending on the laser’s capabilities. Typically, sheets up to 1 inch thick can be cut with high precision.

Q: Can laser-cut wooden sheets be painted or stained?

A: Yes, laser-cut wooden sheets can be painted, stained, or finished to enhance their appearance and durability. Sanding the surface before finishing is recommended for a smooth finish.

Q: What are the safety precautions for laser cutting wooden sheets?

A: Proper ventilation is crucial to remove fumes and smoke produced during laser cutting. Eye protection and protective clothing should also be worn to prevent any potential hazards.