Woodworking Laser Cutter: A Comprehensive Guide

Introduction

Woodworking laser cutters have revolutionized the woodworking industry, enabling precise, efficient, and versatile cutting of various wood materials. This article provides a comprehensive guide to woodworking laser cutters, covering their benefits, types, applications, and factors to consider when choosing the right cutter for your needs.

Table of Content

- 1 Woodworking Laser Cutter: A Comprehensive Guide

- 1.1 Introduction

- 2 H1: Benefits of Woodworking Laser Cutters

- 2.2 H2: Efficient Production

- 2.3 H2: Versatility

- 3 H1: Types of Woodworking Laser Cutters

- 3.4 H2: CO2 Laser Cutters

- 3.5 H2: Fiber Laser Cutters

- 4 H1: Benefits of Woodworking Laser Cutters

- 4.6 H2: Precision Cutting

- 4.7 H2: Efficient Production

- 5 H1: Applications of Woodworking Laser Cutters

- 5.8 H2: Furniture Making

- 5.9 H2: Cabinetry

- 5.10 H2: Toys and Games

- 6 H1: Factors to Consider When Choosing a Woodworking Laser Cutter

- 6.11 H2: Power

- 6.12 H2: Bed Size

- 6.13 H2: Software and Controls

- 7 H1: Conclusion

- 8 FAQs

H1: Benefits of Woodworking Laser Cutters

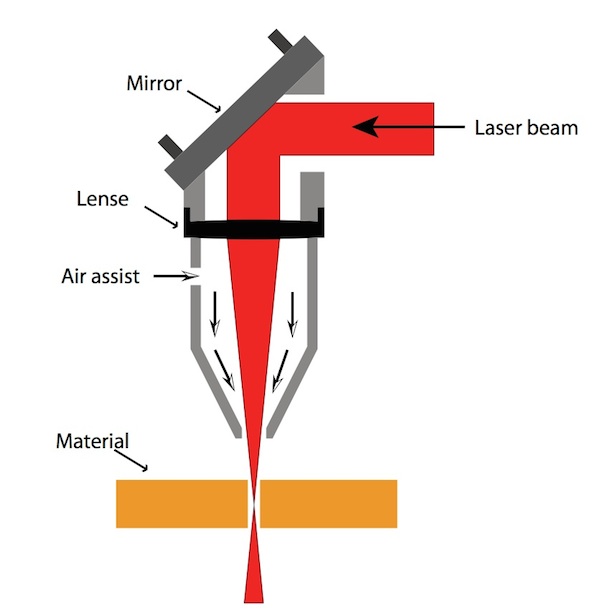

Laser cutters utilize a focused beam of light to vaporize material, resulting in highly precise cuts with minimal distortion. This precision enables intricate designs and complex cuts, making it ideal for creating custom furniture, cabinetry, and other detailed woodworking projects.

H2: Efficient Production

Laser cutters automate the cutting process, increasing productivity and reducing labor costs. By eliminating the need for manual cutting, businesses can produce high volumes of parts quickly and consistently.

H2: Versatility

Woodworking laser cutters can process a wide range of wood materials, including hardwoods, softwoods, plywood, and MDF. This versatility allows for the production of a diverse array of products, from furniture and cabinetry to toys and decorative items.

H1: Types of Woodworking Laser Cutters

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: CO2 Laser Cutters

CO2 laser cutters are the most common type used in woodworking. They emit a beam of carbon dioxide gas, which is heated to produce a focused laser. CO2 lasers offer high power and precision, making them suitable for a wide range of applications.

H2: Fiber Laser Cutters

Fiber laser cutters utilize a beam of fiber-optic cable, which is pumped with a laser diode to produce a high-energy beam. Fiber lasers are known for their speed, efficiency, and ability to cut reflective materials like metals.

Woodworking laser cutters have revolutionized the woodworking industry, enabling precise, efficient, and versatile cutting of various wood materials. This article provides a comprehensive guide to woodworking laser cutters, covering their benefits, types, applications, and factors to consider when choosing the right cutter for your needs.

- Wooden Laser Cut Flowers H1: Wooden Laser Cut Flowers: A Guide To Crafting Enchanting Floral Decor

- Best Wood Laser Engraver Best Wood Laser Engraver: A Comprehensive Guide To Choosing The Perfect Machine

- Wood Laser Cutter Lamp H1: Illuminate Your Space With A Captivating Wood Laser Cutter Lamp

- Wooden Laser Cut Christmas Tree Wooden Laser Cut Christmas Tree: A Unique And Eco-Friendly Holiday Decoration

- A Wood Laser Cutter A Comprehensive Guide To Wood Laser Cutters

H1: Benefits of Woodworking Laser Cutters

H2: Precision Cutting

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutters utilize a focused beam of light to vaporize material, resulting in highly precise cuts with minimal distortion. This precision enables intricate designs and complex cuts, making it ideal for creating custom furniture, cabinetry, and other detailed woodworking projects.

H2: Efficient Production

Laser cutters automate the cutting process, increasing productivity and reducing labor costs. By eliminating the need for manual cutting, businesses can produce high volumes of parts quickly and consistently.

H1: Applications of Woodworking Laser Cutters

H2: Furniture Making

Laser cutters are widely used in furniture making to create intricate designs, custom shapes, and precise joinery. They can cut complex curves, curves, and intricate patterns with ease.

H2: Cabinetry

Laser cutters are essential in cabinetry for creating precise cuts, miter joints, and dovetails. They enable the production of high-quality cabinets with consistent dimensions and finishes.

H2: Toys and Games

Woodworking laser cutters are perfect for creating custom toys, games, and puzzles. The precision cutting capabilities allow for the creation of detailed and intricate designs.

H1: Factors to Consider When Choosing a Woodworking Laser Cutter

H2: Power

The power of a laser cutter determines its cutting speed and depth. Higher-power lasers can cut thicker materials and achieve faster cutting speeds.

H2: Bed Size

The bed size of a laser cutter refers to the maximum size of material it can cut. Consider the size of your projects when selecting a laser cutter with an appropriate bed size.

H2: Software and Controls

The software and controls of a laser cutter determine its ease of use and the level of precision it offers. Look for cutters with user-friendly software and intuitive controls.

H1: Conclusion

Woodworking laser cutters have become indispensable tools in the woodworking industry, offering precision, efficiency, and versatility. By understanding the benefits, types, applications, and factors to consider when choosing a laser cutter, you can make an informed decision that will enhance your woodworking capabilities and take your projects to the next level.

FAQs

Q: What materials can a woodworking laser cutter cut?

A: Woodworking laser cutters can cut a wide range of wood materials, including hardwoods, softwoods, plywood, and MDF.

Q: How does a laser cutter work?

A: Laser cutters emit a focused beam of light that vaporizes material, resulting in highly precise cuts.

Q: What is the difference between a CO2 laser cutter and a fiber laser cutter?

A: CO2 laser cutters use carbon dioxide gas, while fiber laser cutters use fiber-optic cable to generate the laser beam. Fiber laser cutters are faster and more efficient, but CO2 lasers offer higher power and precision.